Preparation method of local anesthetic liposome

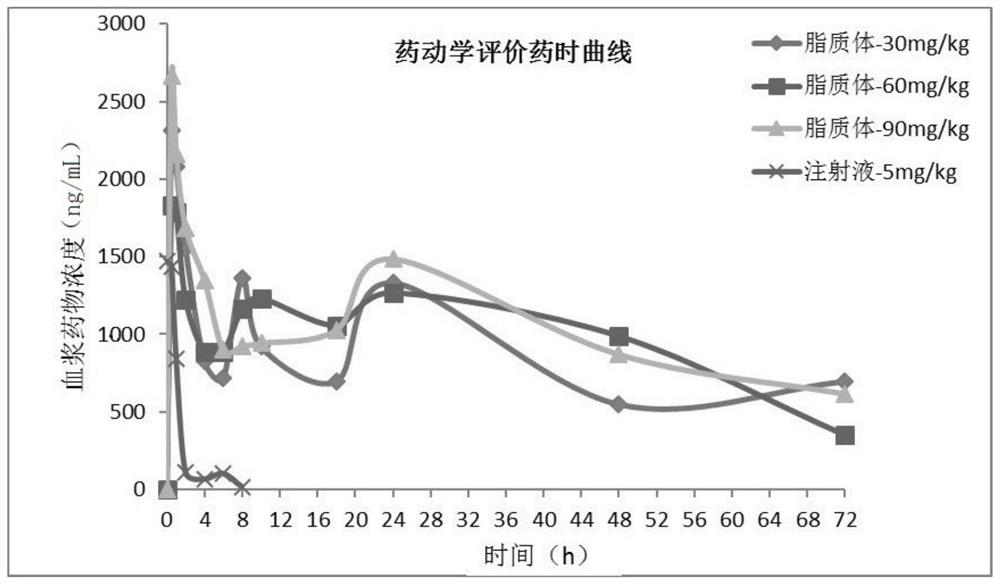

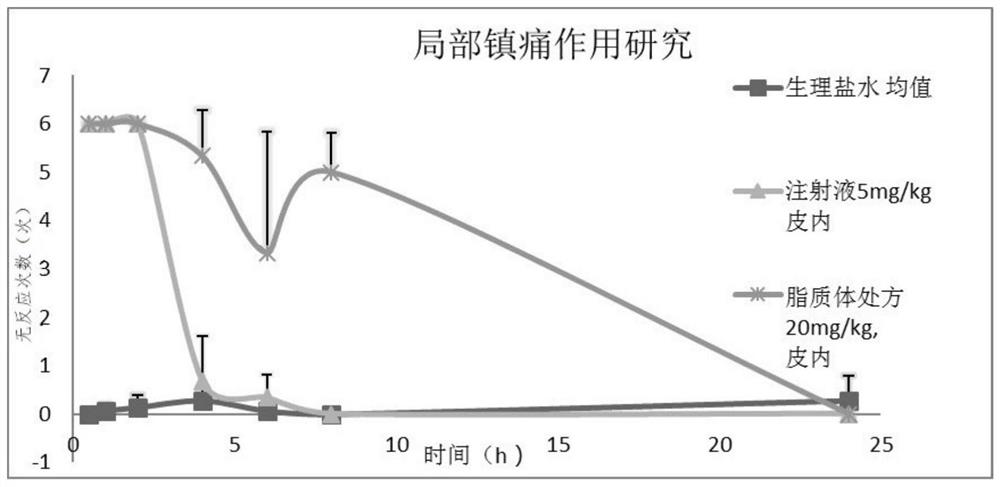

A technology of local anesthetics and liposomes, which is applied in the fields of anesthetics, liposome delivery, pharmaceutical formulations, etc., can solve the problems of low encapsulation efficiency of liposome products, low particle size uniformity, and complicated preparation methods, and achieve improved The effects of entrapment efficiency, prolonged residence time, and simple and easy preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method of preparation of ropivacin liposomes, the specific steps are as follows:

[0034] A. Preparation of white liposomes: 20 ml of 0.02 mol / L phosphate buffer, slowly added with a syringe to DEPC (diel phosphatidylcholine) 240 mg and chooseol 160 mg of trichloromethane solution (V organic phase: V water phase = 1: 1), high speed stirred emulsifue until a stable W / O type emulsion is formed, and the resulting emulsion is reduced to remove trichloromethane in a rotary evaporator (35 ° C) to form a uniform film, and then add appropriate amount of phosphate buffer. The phospholipin film was continued to evaporate, i.e., the uniform liposome mixing solution was obtained, and then the polycarbonate film was used to obtain a blank liposome.

[0035] B. Blank liposome ultrafiltration concentration: Overhaplify the blank liposomes in step A, wherein the film material is a polyether sulfone, and the elongated molecular weight is 300 kDa. The ultrafiltration membrane assembly ...

Embodiment 2

[0038] A method of preparation of ropivacin liposomes, the specific steps are as follows:

[0039] A. Preparation of white liposomes: 20 ml of 0.02 mol / L phosphate buffer, slowly added with a syringe to DEPC (diel phosphatidylcholine) 240 mg and chooseol 160 mg of trichloromethane solution (V organic phase: V water phase = 1: 1), high speed stirred emulsifue until a stable W / O type emulsion is formed, and the resulting emulsion is reduced to remove trichloromethane in a rotary evaporator (35 ° C) to form a uniform film, and then add appropriate amount of phosphate buffer. The phospholipin film was continued to evaporate, i.e., the uniform liposome mixing solution was obtained, and then the polycarbonate film was used to obtain a blank liposome.

[0040] B. Blank liposome ultrafiltration concentration: Ultrafiltrate the blank liposomes in step A. The film material is a polyether sulfone, and the molecular weight is 100 kDa. The ultrafiltration membrane assembly film is 0.5 μm. ...

Embodiment 3

[0044] A method of preparation of ropivacin liposomes, the specific steps are as follows:

[0045] A. Preparation of white liposomes: 20 ml of 0.02 mol / L phosphate buffer, slowly added with a syringe to DEPC (diel phosphatidylcholine) 240 mg and chooseol 160 mg of trichloromethane solution (V organic phase: V water phase = 1: 1), high speed stirred emulsifue until a stable W / O type emulsion is formed, and the resulting emulsion is reduced to remove trichloromethane in a rotary evaporator (35 ° C) to form a uniform film, and then add appropriate amount of phosphate buffer. The phospholipin film was continued to evaporate, i.e., the uniform liposome mixing solution was obtained, and then the polycarbonate film was used to obtain a blank liposome.

[0046] B. Blank liposome ultrafiltration concentration: Ultrafiltrate the blank liposomes in step A. The membrane material is a polyether sulfone, and the medium is 100 kDa, the ultrafiltration membrane assembly film is 0.5 μm, the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com