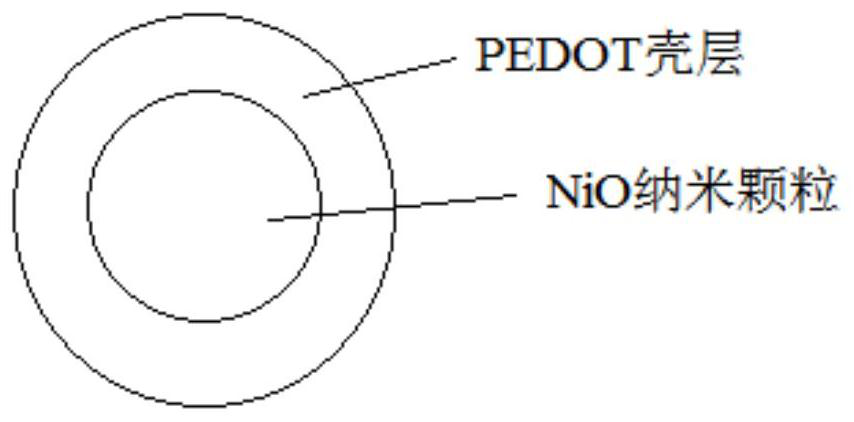

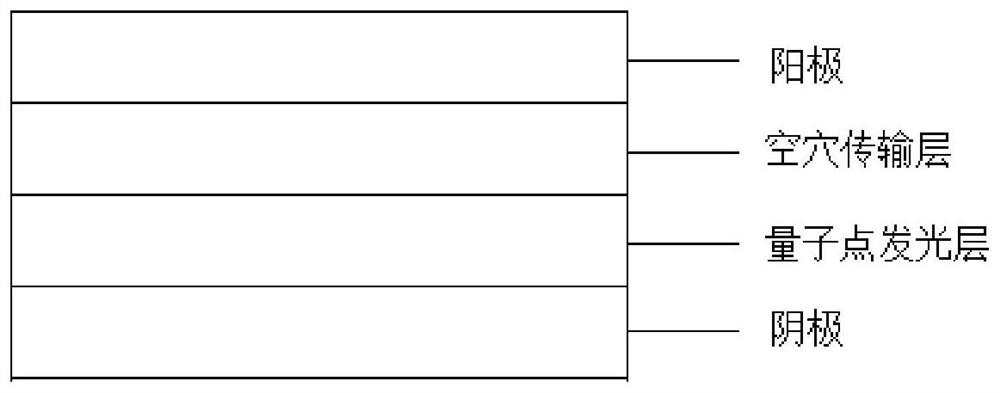

Nano material, preparation method thereof, quantum dot light-emitting diode and preparation method of quantum dot light-emitting diode

A technology of quantum dot luminescence and nanomaterials, applied in the field of display, can solve the problems of easy agglomeration and low hole transport performance, and achieve the effects of improving performance, improving luminous efficiency, and reducing the influence of luminous efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

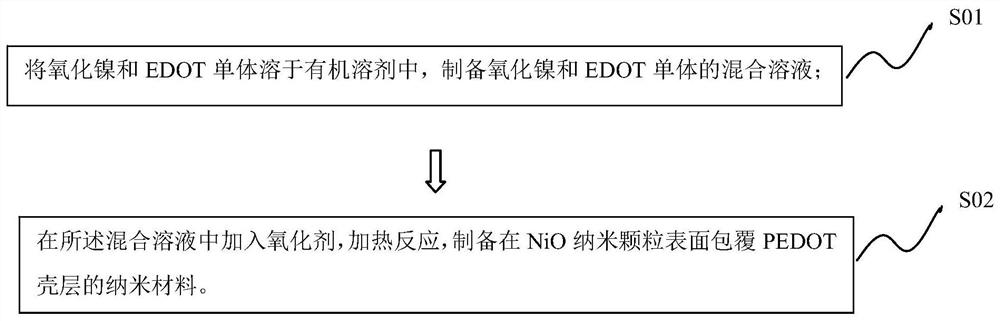

[0031] Correspondingly, combine figure 2 , The second aspect of the embodiment of the present invention provides a method for preparing a nanomaterial, comprising the following steps:

[0032] S01. dissolving nickel oxide and EDOT monomer in an organic solvent to prepare a mixed solution of nickel oxide and EDOT monomer;

[0033] S02. Adding an oxidant to the mixed solution, heating and reacting to prepare a nanomaterial coated with a PEDOT shell on the surface of the NiO nanoparticle.

[0034] The preparation method of the nanomaterial provided in the embodiment of the present invention only needs to dissolve nickel oxide and EDOT monomer in an organic solvent, and then add an oxidizing agent to react. The method is simple to operate and easy to realize large-scale preparation. More importantly, the nanomaterial prepared by the method provided in the embodiment of the present invention can improve the hole transport ability, and when used as the hole transport layer materi...

Embodiment 1

[0083] A preparation method of NiO / PEDOT core-shell nanomaterial, comprising the following steps:

[0084] Add an appropriate amount of nickel chloride to 50ml of ethanol to form a nickel salt solution with a nickel ion concentration of 0.5mol / L, stir and dissolve at a temperature of 70°C, and follow the OH - : Ni 2+ Add sodium hydroxide ethanol solution (10ml ethanol) at a molar ratio of 2:1 (pH=12). Stirred at 70°C for 4 h to obtain a homogeneous transparent solution. After the solution was cooled, it was precipitated with ethyl acetate, and after centrifugation, it was dissolved with a small amount of ethanol (repeated operation, washed 3 times), and dried to obtain NiO nanoparticles.

[0085] Add NiO nanoparticles and EDOT monomer into 30ml ethanol to form a solution with a total concentration of 0.5mol / L, in which the molar ratio of Ni:EDOT is 1:0.5. Then stir and dissolve at a temperature of 70°C, according to EDOT monomer: Fe 3+ The molar ratio is 1:1 ratio, adding ...

Embodiment 2

[0087] A preparation method of NiO / PEDOT core-shell nanomaterial, comprising the following steps:

[0088] Add an appropriate amount of nickel chloride to 50ml of methanol to form a nickel salt solution with a nickel ion concentration of 0.5mol / L, stir and dissolve at a temperature of 60°C, and - : Ni 2+ A methanol solution of sodium hydroxide (10 ml of methanol) was added at a molar ratio of 2:1 (pH=12). Stirring at 60° C. for 4 h gave a homogeneous transparent solution. After the solution was cooled, it was precipitated with ethyl acetate, and after centrifugation, it was dissolved with a small amount of ethanol (repeated operation, washed 3 times), and dried to obtain NiO nanoparticles.

[0089] Add NiO nanoparticles and EDOT monomer into 30ml methanol to form a solution with a total concentration of 0.8mol / L, in which the molar ratio of Ni:EDOT is 1:0.6. Then stir and dissolve at a temperature of 60° C., and add a methanol solution of ammonium persulfate (5 ml of methan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com