Double-particle-size pitch repeatedly-coated shaped graphite silicon-carbon negative electrode material as well as preparation method and application of graphite silicon carbon negative electrode material

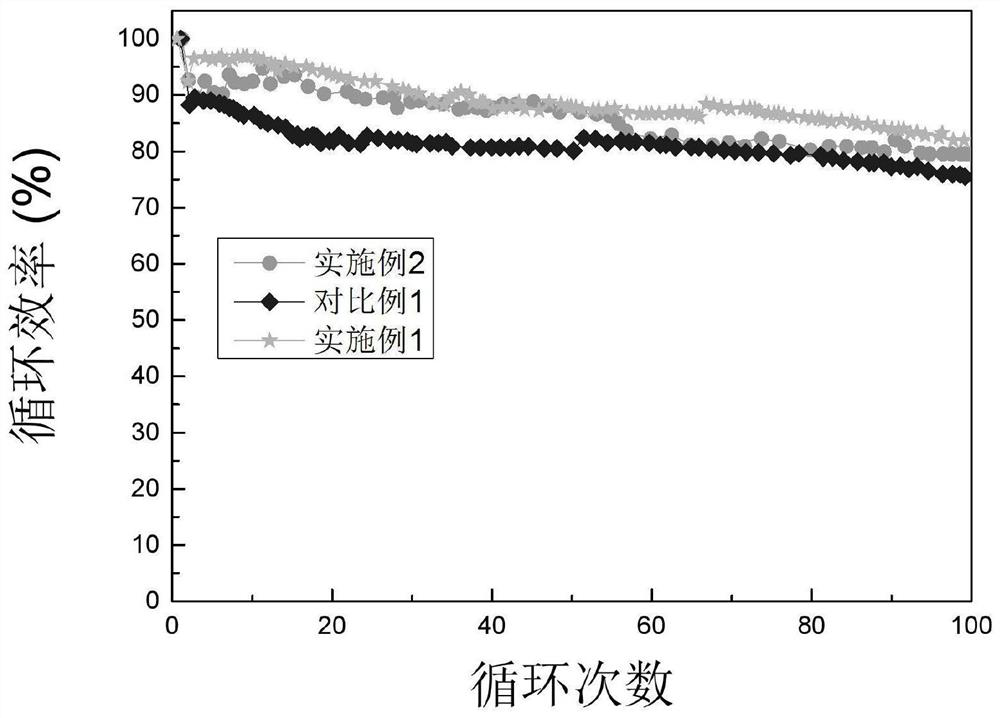

A negative electrode material, multiple coating technology, applied in the direction of nanotechnology for materials and surface science, negative electrodes, battery electrodes, etc., can solve the unsatisfactory coating effect of porous graphite, the difficulty of compounding nano-silicon, Poor material conductivity and other issues, to avoid nano-silicon exposure, improve high-rate discharge capacity, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment 1 provides a method for preparing a graphite silicon carbon negative electrode material coated with double particle size pitch multiple times, which specifically includes the following steps:

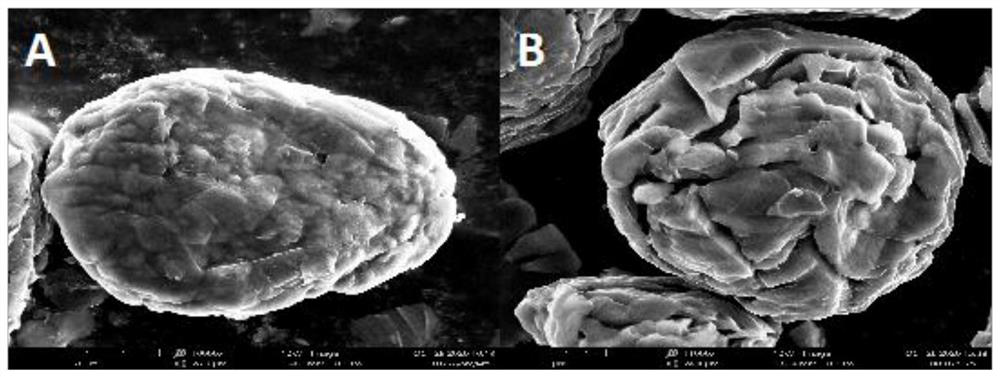

[0028] (1) Place shaped graphite (1600g) with a D50 average particle size of 17μm in a chemical vapor deposition furnace, pump it to a vacuum state, fill it with nitrogen at a rate of 12L / h, and raise the temperature to 420°C at a rate of 8°C / min. After reaching 420°C, fill in silane at a rate of 25L / h, keep the temperature for 2 hours, close the silicon source gas pipeline, enter the automatic cooling program, and take it out after cooling down to normal temperature to obtain shaped graphite with deposited nano-silicon;

[0029] (2) Combine 900g of shaped graphite deposited with silicon, and 100g of mesophase pitch, with an average particle size of D50 of 5.72μm, a rotation speed of 900r / min, and a stirring time of 20min. With circulating water to stabilize the te...

Embodiment 2

[0033] This embodiment 1 provides a method for preparing a graphite silicon carbon negative electrode material coated with double particle size pitch multiple times, which specifically includes the following steps:

[0034] (1) Place shaped graphite (1600g) with a D50 average particle size of 17μm in a chemical vapor deposition furnace, pump it to a vacuum state, fill it with nitrogen at a rate of 12L / h, and raise the temperature to 420°C at a rate of 8°C / min. After reaching 420°C, fill in silane at a rate of 25L / h, keep the temperature for 2 hours, close the silicon source gas pipeline, enter the automatic cooling program, and take it out after cooling down to normal temperature to obtain shaped graphite with deposited nano-silicon;

[0035] (2) Combine 900g of shaped graphite deposited with silicon, and 100g of mesophase pitch, with an average particle size of D50 of 10.27μm, a rotation speed of 900r / min, and a stirring time of 20min. With circulating water to stabilize the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com