Hard carbon binder, negative plate containing hard carbon binder and sodium ion battery

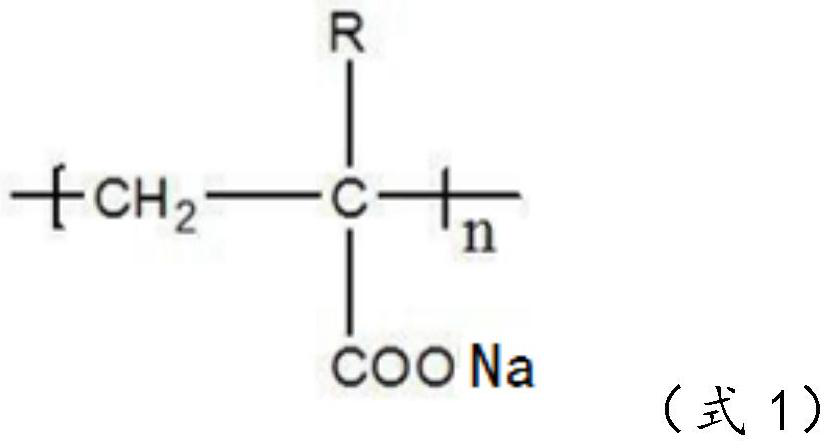

A sodium-ion battery and binder technology, which is applied to battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve problems such as easy decomposition, and achieve the effects of low environmental requirements, short process time, and low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

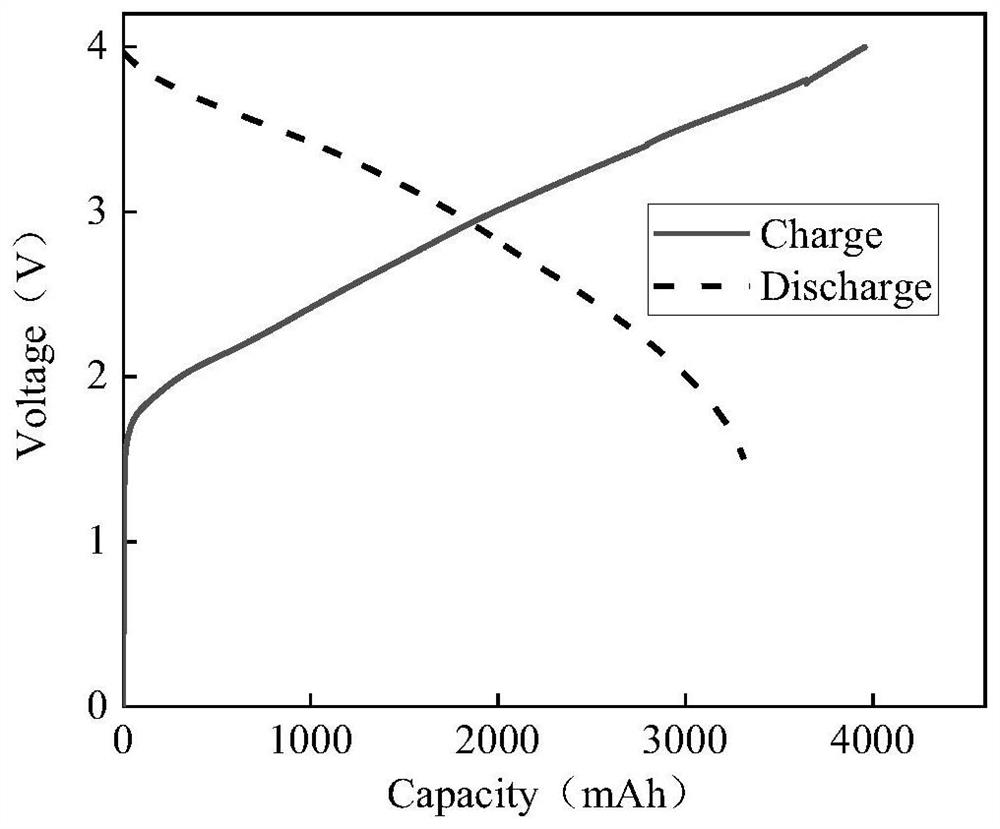

Embodiment 1

[0049] 1) Preparation of positive pole piece: 95wt% copper iron manganese sodium oxide O3-Na[Cu 0.22 Fe 0.3 Mn 0.48] O 2 Mix with 3wt% acetylene black, use a low-speed mixer to stir at 30r / min for 20min, then add 40% solid content polytetrafluoroethylene (PTFE) emulsion, the addition amount is 2wt%, stir at 30r / min for 2 Hour. Then, the prepared slurry was evenly rolled on an aluminum foil with a thickness of 20 μm, with an areal density of 100 mg / cm 2 , the positive electrode sheet is prepared after drying, slitting and die-cutting.

[0050] 2) Preparation of negative pole piece: 95wt% of anthracite-based hard carbon material and 3wt% of acetylene black were mixed, stirred at a speed of 30r / min for 20min with a low-speed mixer, and then added with 40% solid content of sodium polyacrylate emulsion, and the addition amount was 2 wt %, stirring at 30 r / min for 2 hours. Then, the prepared slurry was evenly rolled on an aluminum foil with a thickness of 20 μm, with an areal ...

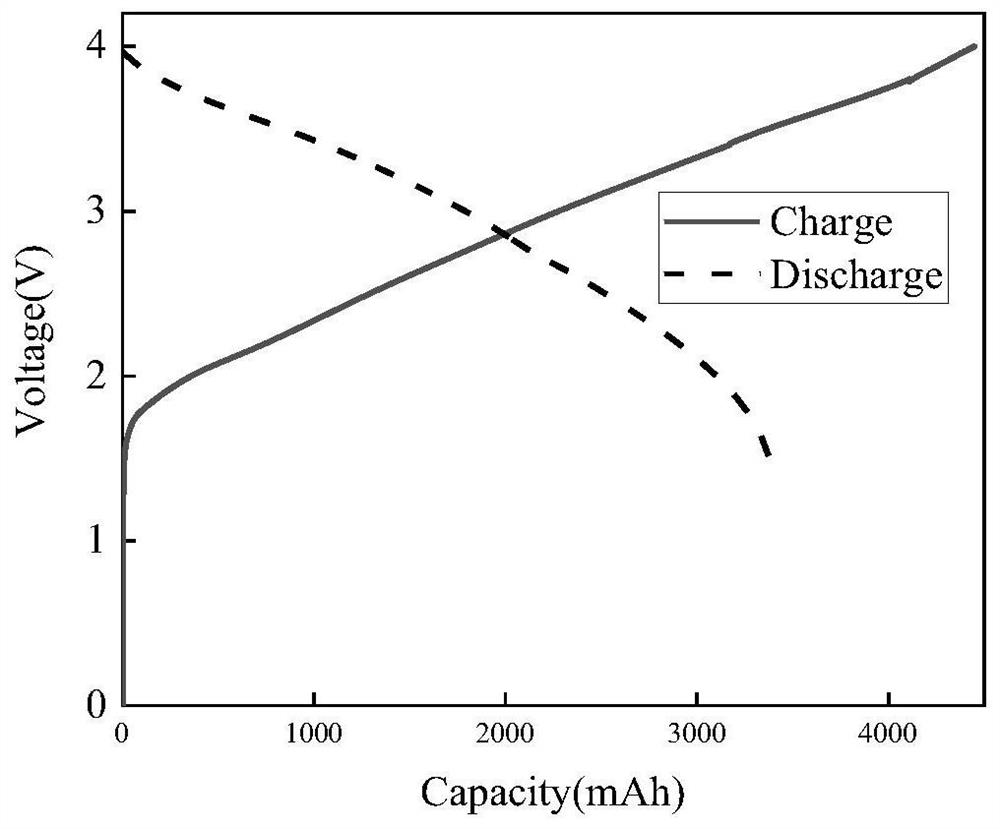

Embodiment 2

[0061] 1) The preparation of the positive electrode plate is the same as that of Example 1.

[0062] 2) Preparation of negative pole piece: 95wt% of anthracite-based hard carbon material and 3wt% of acetylene black were mixed, stirred at a speed of 30r / min for 20min with a low-speed mixer, and then added with 40% solid content of PAAS and the monomer acrylic acid on the chain. The ester copolymer was added in an amount of 2 wt %, and the mixture was stirred at a rotational speed of 30 r / min for 2 hours. Then, the prepared slurry was evenly rolled on an aluminum foil with a thickness of 20 μm, with an areal density of 63 mg / cm 2 After drying, slitting and die-cutting, the dry-process negative electrode sheet is prepared.

[0063] 3) 0880138 dry-process sodium ion half-cell was prepared according to the same method as in Example 1 above; the design capacity was 4.5Ah;

[0064] 4) the sodium ion half-cell of gained is baked in the high temperature vacuum box for 24 hours, the l...

Embodiment 3

[0067] 1) The preparation of the positive electrode plate is the same as that of Example 1.

[0068] 2) Preparation of negative pole piece: 95wt% of anthracite-based hard carbon material and 3wt% of acetylene black were mixed, stirred at a speed of 30r / min for 20min using a low-speed mixer, and then added 40% solid content of PAAS and the monomer vinyl acetate on the chain The ester copolymer was added in an amount of 2 wt %, and the mixture was stirred at a rotational speed of 30 r / min for 2 hours. Then, the prepared slurry was evenly rolled on an aluminum foil with a thickness of 20 μm, with an areal density of 63 mg / cm 2 After drying, slitting and die-cutting, the dry-process negative electrode sheet is prepared.

[0069] 3) 0880138 dry-process sodium ion half-cell was prepared according to the same method as in Example 1 above; the design capacity was 4.5Ah;

[0070] 4) the sodium ion half-cell of gained is baked in the high temperature vacuum box for 24 hours, the liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com