Anti-pollution and high-flux modified polymer separation membrane and preparation method thereof

A polymer and separation membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of harsh reaction conditions, increase the application cost of separation membranes, and difficult to control the reaction effectively, and achieve simple equipment. , to achieve large-scale industrial application, the effect of water content improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] First, prepare 500 mL of ferrous ammonium sulfate aqueous solution with a mass fraction of 0.1% with deionized water. The function of ferrous ammonium sulfate is to prevent homopolymerization of monomers in the solution. Then, drop 2.5g of acrylic acid in the ferrous ammonium sulfate aqueous solution that is prepared (in order to prevent acrylic acid from reacting in the air, when dropping, the tail of the dropping tube should extend below the liquid level of the ferrous ammonium sulfate aqueous solution ), that is, the grafting solution is prepared.

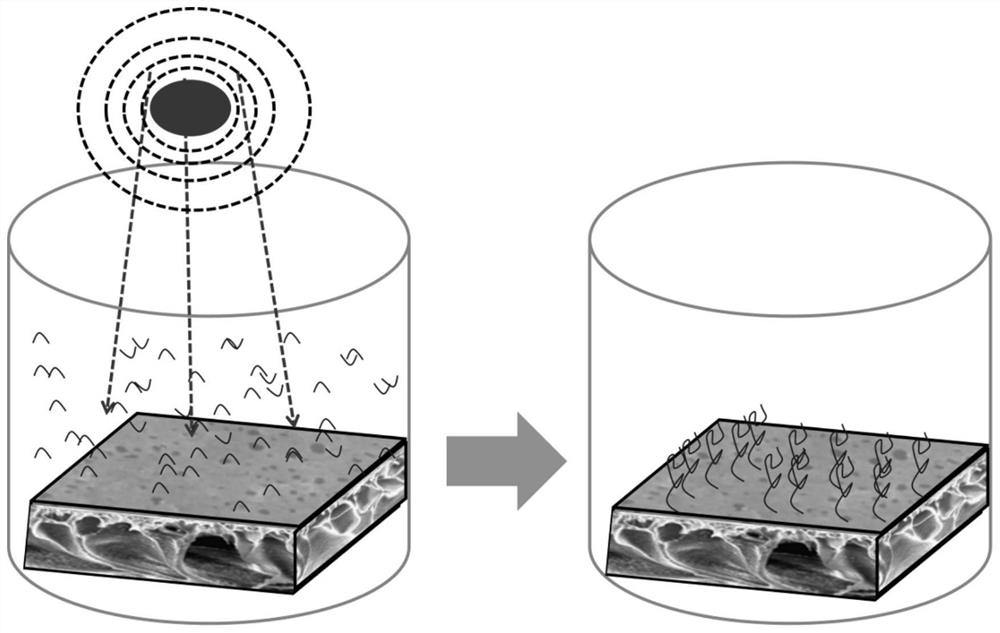

[0042] In the stage of preparing PVDF membrane, the PVDF with non-woven support with a pore size of 0.1 μm was cut into a membrane with a size of 10 cm×10 cm, rinsed with deionized water, and then soaked in deionized water for 24 hours. Then, put the clean PVDF membrane into the radiant tube, and add 200 mL of grafting solution into the radiant tube. The radiant tube was sealed with petroleum jelly and filled with nitrog...

Embodiment 2

[0044] First, prepare 500 mL of ferrous ammonium sulfate aqueous solution with a mass fraction of 0.1% with deionized water. The function of ferrous ammonium sulfate is to prevent homopolymerization of monomers in the solution. Then, in the ferrous ammonium sulfate aqueous solution that prepares, drop 3g acrylamide (in order to prevent acrylamide from reacting in the air, when dripping, the tail of the dropping tube should extend into the liquid level of the ferrous ammonium sulfate aqueous solution Below), the grafting solution is prepared.

[0045] In the stage of preparing PVDF membrane, the PVDF with non-woven support with a pore size of 0.1 μm was cut into a membrane with a size of 10 cm×10 cm, rinsed with deionized water, and then soaked in deionized water for 24 hours. Then, put the clean PVDF membrane into the radiant tube, and add 200 mL of grafting solution into the radiant tube. The radiant tube was sealed with petroleum jelly and filled with nitrogen for 30 min to...

Embodiment 3

[0047] First, 500 mL of ferrous ammonium sulfate aqueous solution with a mass fraction of 0.3% was prepared with deionized water. The function of ferrous ammonium sulfate was to prevent homopolymerization of monomers in the solution. Then, add 1g of acrylic acid and 2g of acrylamide dropwise to the prepared ferrous ammonium sulfate aqueous solution (in order to prevent the monomer from reacting in the air, when dropping, the tail of the dropping tube should extend into the ferrous ammonium sulfate aqueous solution below the liquid level), that is, the grafting solution is prepared.

[0048] In the stage of preparing PVDF membrane, the PVDF with non-woven support with a pore size of 0.1 μm was cut into a membrane with a size of 10 cm×10 cm, rinsed with deionized water, and then soaked in deionized water for 24 hours. Then, put the clean PVDF membrane into the radiant tube, and add 200 mL of grafting solution into the radiant tube. The radiant tube was sealed with petroleum jel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com