Preparation method of negative electrode powder of fast-charging type lithium ion battery and application of negative electrode powder in lithium ion battery

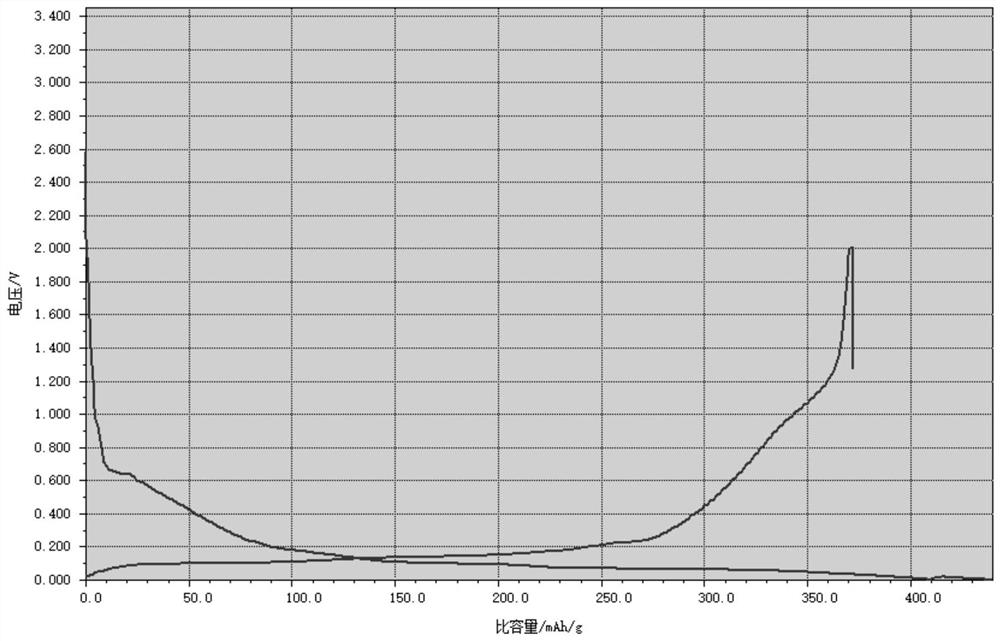

A lithium-ion battery and negative electrode technology, which is applied in the preparation of fast-charging lithium-ion battery negative electrode powder and its application in lithium-ion batteries, can solve the problems of reduced reversible capacity, deterioration of battery performance, and large polarization voltage. Achieve the effects of small distribution gradient of lithium intercalation, good battery cycle life, and high constant current and constant voltage ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

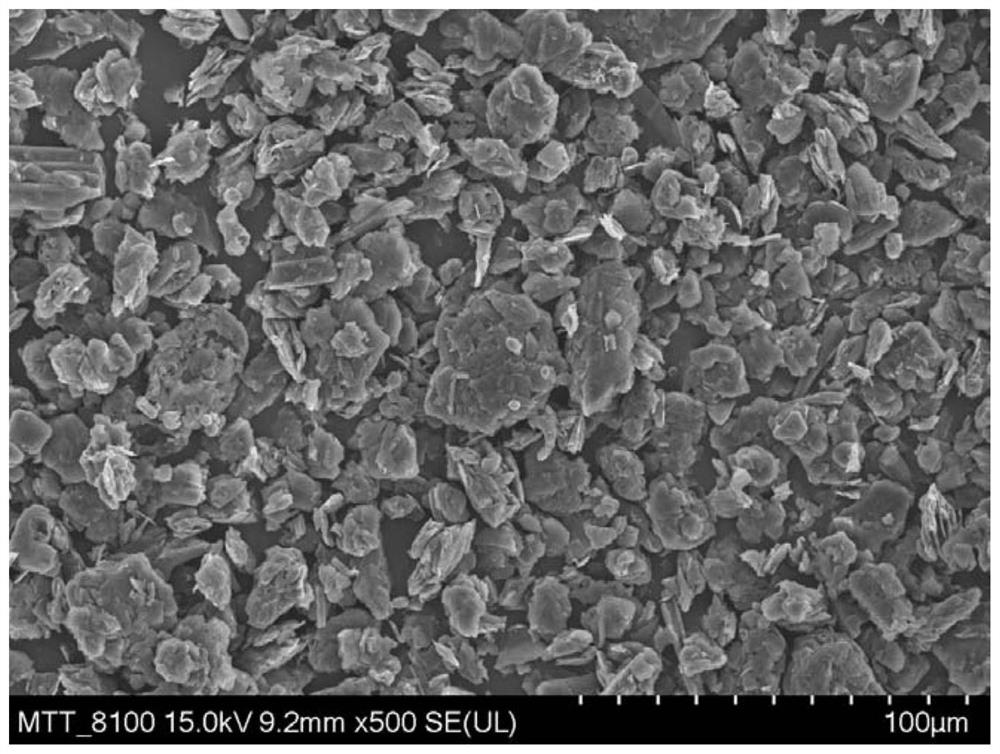

[0041] Weigh 5Kg of phenolic resin powder and fill it into a graphite crucible, put it into a box-type furnace and heat it according to the following program in an argon atmosphere: 150°C for 2h, 350°C for 5h, and 700°C for 5h. Use a pulverizer to pulverize to D50=5μm to obtain hard carbon particles; crush 12Kg needle coke raw coke to D50=5μm, fill the reshaped material into a graphite crucible, and heat it in an Acheson graphitization furnace for 2900 Graphite at high temperature above ℃, crush and sieve to obtain graphite particles; put the obtained hard carbon particles and graphite particles into the fusion machine, add 5Kg phenolic resin solution in stages, after fusion treatment for 5 hours, put the materials into the box furnace, Introduce argon gas and heat at 500°C for 5 hours, after cooling and taking out, crush and sieve to prepare carbon particles with porous double-layer structure; add carbon particles with porous double-layer structure and 2.3Kg high-temperature p...

Embodiment 2

[0043] Weigh 4Kg of phenolic resin powder and fill it into a graphite crucible, put it into a box-type furnace and heat it in an argon atmosphere according to the following program: 150°C for 2h, 400°C for 5h, and 800°C for 10h. Use a pulverizer to grind to D50=6μm to obtain hard carbon particles; grind 7.5Kg of needle coke raw coke to D50=5μm, fill the material after shaping into a graphite crucible, and pass through Acheson graphitization furnace Graphitization at a high temperature above 2900°C, crushing and sieving to obtain graphite particles; put the obtained hard carbon particles and graphite particles into the fusion machine, add 4Kg phenolic resin solution in stages, and after fusion treatment for 3 hours, put the materials into the box furnace , put in argon gas and heat at 700°C for 4 hours, after cooling and taking out, crush and sieve to prepare carbon particles with porous double-layer structure; add carbon particles with porous double-layer structure and 1.8Kg hi...

Embodiment 3

[0045] Weigh 6Kg of phenolic resin powder and fill it into a graphite crucible, put it into a box-type furnace and heat it in an argon atmosphere according to the following program: 150°C for 2h, 750°C for 5h, and 1200°C for 10h. Use a pulverizer to pulverize to D50=4μm to obtain hard carbon particles; crush 15Kg needle coke raw coke to D50=6μm, fill the reshaped material into a graphite crucible, and heat it in an Acheson graphitization furnace for 2900 Graphite at high temperature above ℃, crush and sieve to obtain graphite particles; put the obtained hard carbon particles and graphite particles into the fusion machine, add 6Kg phenolic resin solution in stages, and after fusion treatment for 4 hours, put the materials into the box furnace. Pass in argon gas and heat at 600°C for 7 hours. After cooling and taking out, crush and sieve to prepare carbon particles with a porous double-layer structure; add the carbon particles with a porous double-layer structure and 3Kg of high-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com