Bimetal composite radiator capable of reducing friction abnormal sound and preparation method thereof

A bimetallic composite pipe and radiator technology, applied in heat exchange equipment, lighting and heating equipment, coating, etc., can solve the problems of difficult operation, time-consuming and laborious, etc., and achieve improved heat conduction effect, simple preparation method, quiet and comfortable The effect of using the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 50kg of environmentally friendly water-based epoxy resin emulsion, 5kg of titanium dioxide, 20kg of graphene powder, 3kg of water-based paint additives, 3kg of surfactants, 5kg of defoamers, 5kg of polyurethane thickeners, 3kg of kaolin, 3kg of pure acrylic emulsion, anti-corrosion 3kg of the agent was stirred and mixed, and the thermally conductive coating was obtained after mixing evenly.

Embodiment 2

[0045](1) Select high-quality low-carbon steel pipes for pickling and phosphating (oil removal---rust removal---water washing---neutralization---water washing---surface adjustment---phosphating---water washing-- -passivation---drying) treatment to lay a good surface foundation for strengthening the coating adhesion in the next step. Put the phosphating steel pipe on the automatic assembly line of the special tooling table to coat the heat-conducting paint, and avoid the close contact between the pipe and the pipe to prevent the adhesion between the coatings. The thermally conductive coating has good thermal conductivity and strong adhesion. The thickness of the coating should be uniform and controlled at about 40um. Put the coated steel pipe into a baking oven for drying at a temperature of 130°C for 9 minutes.

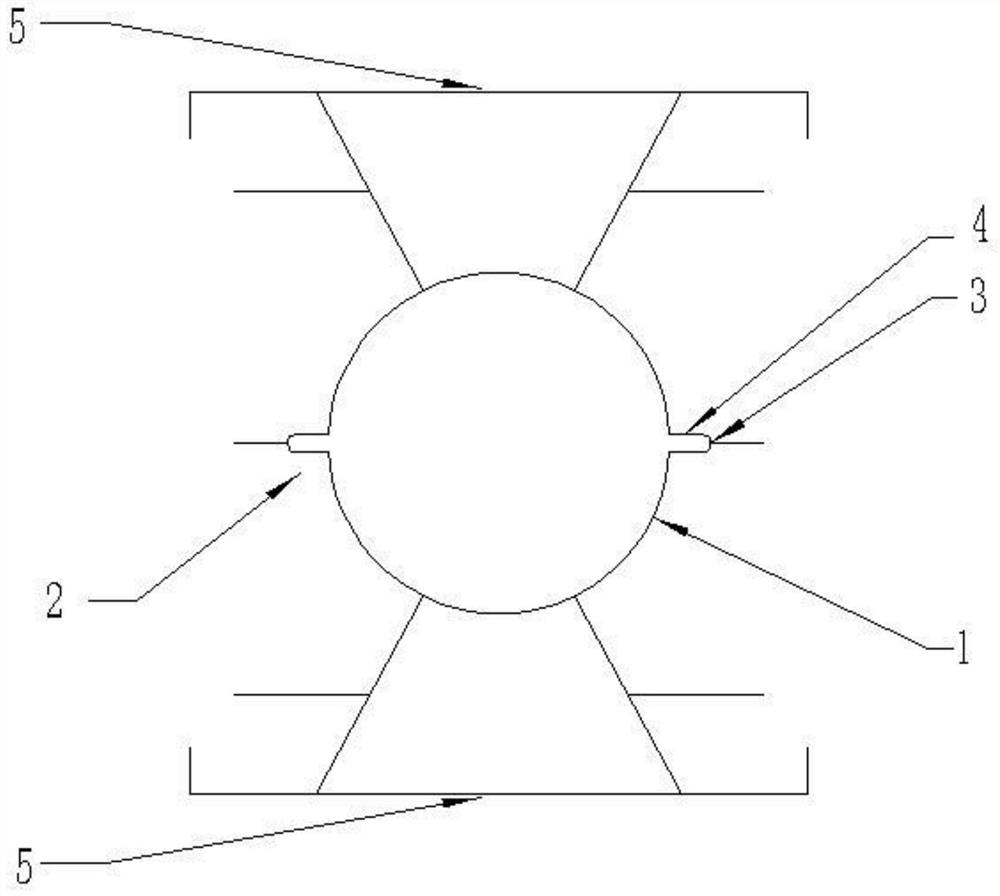

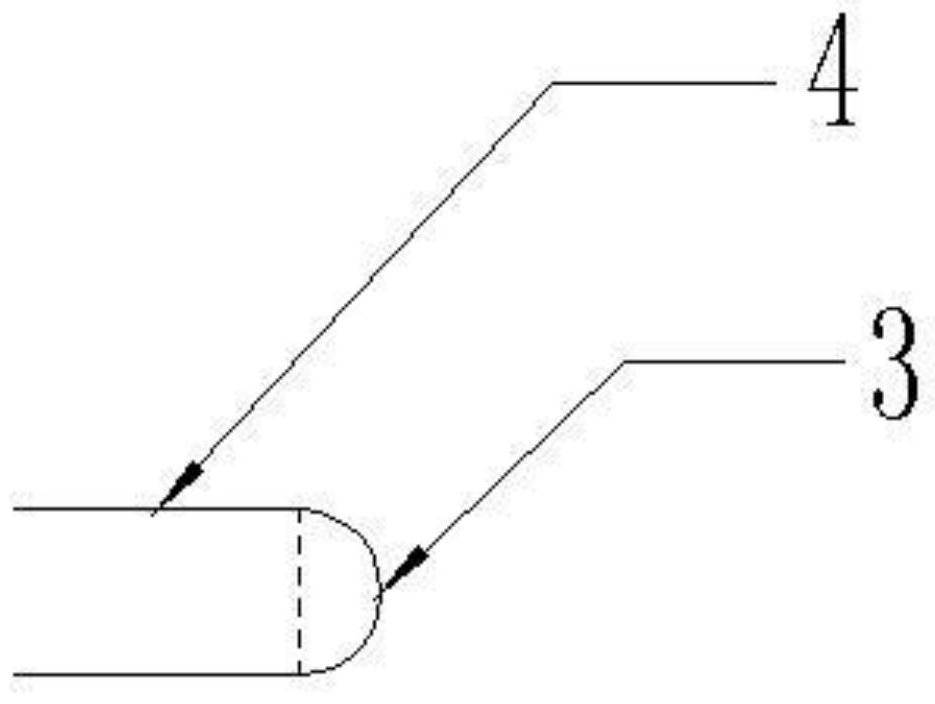

[0046] (2) The aluminum profile should also undergo strict pickling-water washing-alkali corrosion-water washing-chromizing treatment; the coated steel pipe is insert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com