Lutein compound micro-capsule powder and preparation method and application thereof

A technology of lutein and microcapsule powder, applied in the field of lutein compound microcapsule powder and preparation thereof, can solve the problems of complex preparation process, existence of safety risks, oxidation of unsaturated fatty acids, etc., achieves wide application prospect, improves Bioavailability, the effect of increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

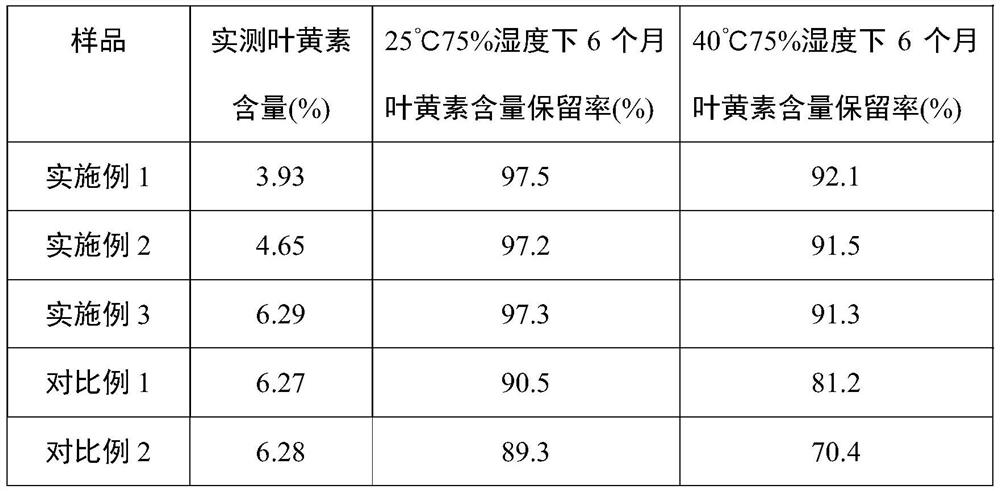

Examples

Embodiment 1

[0036] This embodiment provides a kind of lutein compound microcapsule powder, and its preparation method is as follows:

[0037] (1) Add 10 g of lutein (content 80%) into 65 g of seabuckthorn oil and 15 g of walnut oil, stir and dissolve, then add 0.4 g of vitamin E, and mix evenly to obtain an oil phase.

[0038] (2) Add 70g of maltodextrin, 17g of solid corn syrup, 10g of trehalose, 15g of sodium caseinate, 0.08g of tea polyphenols, 1.5g of sodium ascorbate, 2g of sodium stearoyl lactylate, and 2g of monoglyceride succinate into 200g of pure Dissolve in water at 60°C for 30 minutes with stirring to obtain an aqueous phase.

[0039] (3) Slowly add the oil phase to the water phase for high-speed stirring and emulsification for 60 minutes, and then pass through a high-pressure homogenizer twice, with a homogenization pressure of 40 MPa.

[0040] (4) Dry the emulsion with a spray dryer to obtain lutein compound microcapsule powder. The spray drying conditions are: the air inle...

Embodiment 2

[0042] This embodiment provides a kind of lutein compound microcapsule powder, and its preparation method is as follows:

[0043] (1) Add 10g of lutein (content 80%) into 38g of seabuckthorn oil and 12g of walnut oil and stir to dissolve, then add 0.3g of vitamin E and 0.04g of ascorbyl palmitate, and mix well to obtain an oil phase.

[0044] (2) Add 50g of modified starch, 20g of solid corn syrup, 10g of lactose, 20g of whey protein isolate, 3.5g of sodium ascorbate, 1.5g of monoglyceride fatty acid esters, and 1.7g of sodium stearoyl lactylate into 150g of purified water, and stir at 65°C The aqueous phase was obtained by dissolving for 40 min.

[0045] (3) Slowly add the oil phase to the water phase for high-speed stirring and emulsification for 30 minutes, and then pass through a high-pressure homogenizer twice, with a homogenization pressure of 30 MPa.

[0046] (4) Dry the emulsion with a spray dryer to obtain lutein compound microcapsule powder. The spray drying conditi...

Embodiment 3

[0048] This embodiment provides a kind of lutein compound microcapsule powder, and its preparation method is as follows:

[0049] (1) Add 10g of lutein (content 80%) into 20g of seabuckthorn oil and 10g of walnut oil and stir to dissolve, then add 0.2g of vitamin E and 0.02g of ascorbyl palmitate, and mix evenly to obtain an oil phase.

[0050] (2) Add 40g of modified starch, 25g of zein, 10g of solid corn syrup, 3.5g of sodium ascorbate, 1.5g of monoglyceride fatty acid ester, and 1g of sucrose fatty acid ester into 120g of purified water, stir and dissolve at 65°C for 30 minutes. Aqueous phase was obtained.

[0051] (3) Slowly add the oil phase to the water phase, stir and emulsify at high speed for 40 minutes, and then pass through a high-pressure homogenizer twice, with a homogenization pressure of 40 MPa.

[0052] (4) Dry the emulsion with a spray dryer to obtain lutein compound microcapsule powder. The spray drying conditions are: the air inlet temperature is 180°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com