Composite carrier containing activated carbon and preparation method of composite carrier

A technology of composite carrier and activated carbon, which is applied in the direction of catalyst carrier, chemical instruments and methods, and other chemical processes, can solve the problems of low utilization rate of bulk molecular sieves, improve utilization rate and catalytic efficiency, and solve slow mass transfer rate, The effect of promoting the adsorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

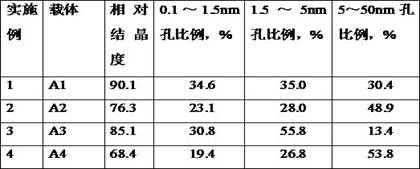

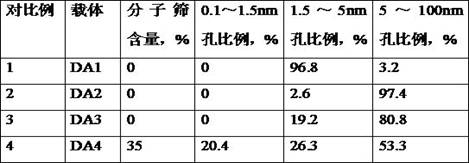

Examples

Embodiment 1

[0045] Wood activated carbon powder (200 mesh, specific surface area 840m 2 / g, average pore diameter 3.47nm) 125g, 325g of silica-alumina clay (46.1% by mass fraction of silica, 39.8% by mass of alumina) after roasting at 800°C, mix evenly, add 40% by mass of alkali-soluble carboxymethyl cellulose Mix and knead 100g of chopped fiber slurry evenly, then add 200g of sodium silicate binder with a mass content of 25% and knead evenly, add an appropriate amount of water and knead, then extrude into strips, dry at 110°C for 4 hours, and cure at 270°C for 3 hours under nitrogen protection. get the precursor. Take 5.0 g of the precursor and add it to 72.0 g of sodium hydroxide solution with a mass concentration of 7.5%, put it into a reactor and heat it in a water bath to 190°C for 4 hours; after cooling to room temperature, wash with distilled water until the pH is 7.9, filter, and dry at 90°C 6h, and roasted at 750°C for 3h under the protection of nitrogen to obtain the activated ...

Embodiment 2

[0048] Coconut shell activated carbon powder (200 mesh, specific surface area 1070m 2 / g, average pore diameter 3.86nm) 100g, 365g of silica-alumina clay (54.6% by mass fraction of silica, 43.5% by mass of alumina) after roasting at 900°C, mix evenly, add 20% by mass of polyester cellulose fiber chopped Mix 125g of silk slurry evenly, then add 100g of sodium silicate binder with a mass content of 35% and knead evenly, add an appropriate amount of water and knead, extrude into strips, dry at 90°C for 4 hours, and cure at 200°C for 5 hours under the protection of nitrogen to obtain a precursor . Add 7.8 g of the precursor to 80.4 g of sodium hydroxide solution with a mass concentration of 10.0%, heat it in a water bath to 130°C, stir evenly and then hydrothermally treat it for 6 hours; after cooling to room temperature, wash with distilled water until the pH is 7.2, filter, and dry at 80°C for 6 hours , and roasted at 700° C. for 3 h under the protection of nitrogen to obtain t...

Embodiment 3

[0051] Coal-based activated carbon powder (300 mesh, specific surface area 780m 2 / g, average pore diameter 4.36nm) 200g, 250g of silica-alumina clay (55.0% by mass fraction of silica, 40.9% by mass of alumina) after roasting at 1000°C, mix evenly, add 35% by mass of hydroxyethyl cellulose fiber short 100g of shredded slurry was mixed evenly, then 167g of sodium silicate binder with a mass content of 30% was added and mixed evenly, an appropriate amount of water was added, mixed and kneaded, extruded into strips, dried at 90°C for 4 hours, cured under nitrogen protection at 260°C for 4 hours, and the precursor body. Add 7.5 g of the precursor to 81.6 g of sodium hydroxide solution with a mass concentration of 8.2%, heat in an oven to 170°C, stir evenly and then hydrothermally treat it for 5 hours; after cooling to room temperature, wash with distilled water until the pH is 7.2, filter, and dry at 100°C for 6 hours , and roasted at 800° C. for 3 h under the protection of nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com