Preparation method of carbon-containing carrier containing cross-linked intercommunicated micron pore channels

A carbon carrier and pore technology, which is applied in the field of preparation of carbon-containing carriers, can solve problems such as the inability to form unobstructed pores, and achieve the effects of improving rapid adsorption capacity, high surface area, and improving mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

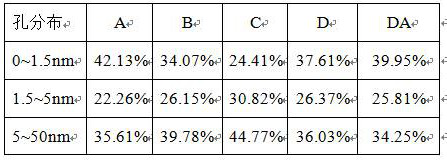

[0031] Roast the silicon-aluminum composite soil at 600°C in a high-temperature furnace, mix 978g with 109g of activated carbon and 100g of polyethylene fiber silk, add 1359g of silica sol with a content of 20% and an appropriate amount of water, mix well, knead and extrude, 90 Dry at ℃ for 6 hours, roast at 300℃ for 4 hours under nitrogen protection, soak in DMF for 24 hours, filter out the solids and dry them, circulate the solids with an aqueous solution containing 1060g of sodium hydroxide for 5 hours, then filter them, dry at 90 for 6 hours, and use nitrogen protection conditions Calcined at 900°C for 6 hours to obtain composite carrier A, the properties of composite carrier A are shown in Table 1.

Embodiment 2

[0033] Roast the silicon-aluminum composite soil at 700°C in a high-temperature furnace, mix 1111g with 444g of activated carbon and 231g of polyester fiber filaments, add 1945g of silica sol with a content of 20% and an appropriate amount of water, mix well, knead and extrude, 90 Dry at ℃ for 6 hours, roast at 280℃ for 4 hours under nitrogen protection, soak in acetone for 24 hours, filter out the solids and dry them, circulate the solids with an aqueous solution containing 1204g of sodium hydroxide for 5 hours, filter them, and dry them at 90 for 6 hours, under nitrogen protection conditions Calcined at 700°C for 6 hours to obtain composite carrier B, the properties of composite carrier B are shown in Table 1.

Embodiment 3

[0035] Roast the silicon-aluminum composite soil at 800°C in a high-temperature furnace, mix 1041g with 1040g of activated carbon and 161g of acrylic fiber filaments, add 2601g of silica sol with a content of 20% and an appropriate amount of water, mix well, knead and extrude, 90°C Dry for 6 hours, roast at 270°C for 4 hours under nitrogen protection, soak in acetone for 24 hours, filter out the solids and dry them, circulate the solids with an aqueous solution containing 1127g of sodium hydroxide for 5 hours, then filter them, and dry them at 90 for 6 hours, under nitrogen protection conditions Calcined at 800°C for 6 hours to obtain composite carrier C, the properties of composite carrier C are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com