Phenanthroimidazole electroluminescent material with circular polarization luminescence as well as preparation method and application thereof

An electroluminescent material and phenanthroimidazole technology, which is applied in the directions of luminescent materials, chemical instruments and methods, circuits, etc., can solve the problems such as the scarcity of material types and the performance to be improved, and achieve commercial application and improve device electrical properties. The effect of electroluminescence performance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

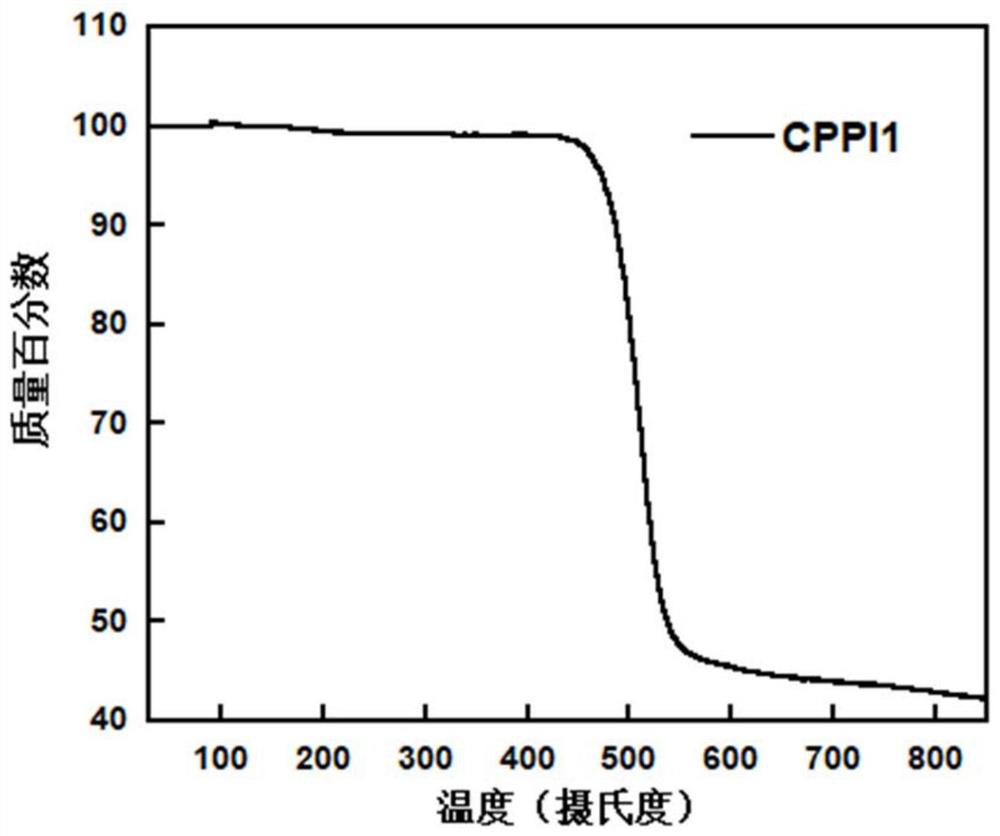

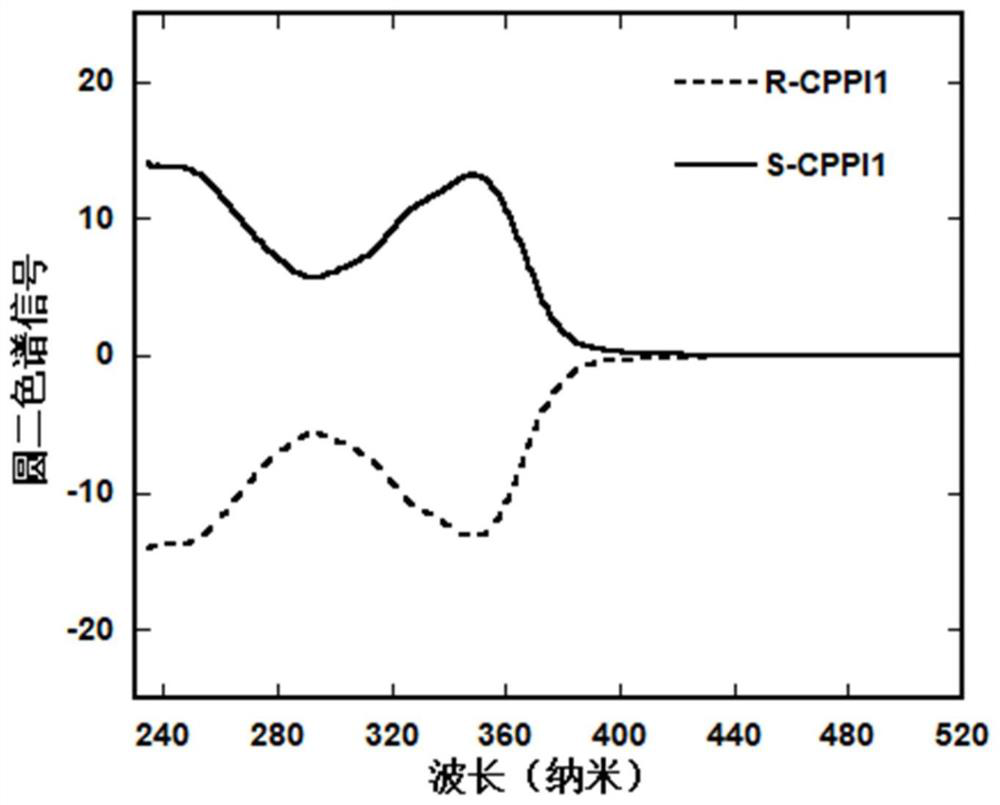

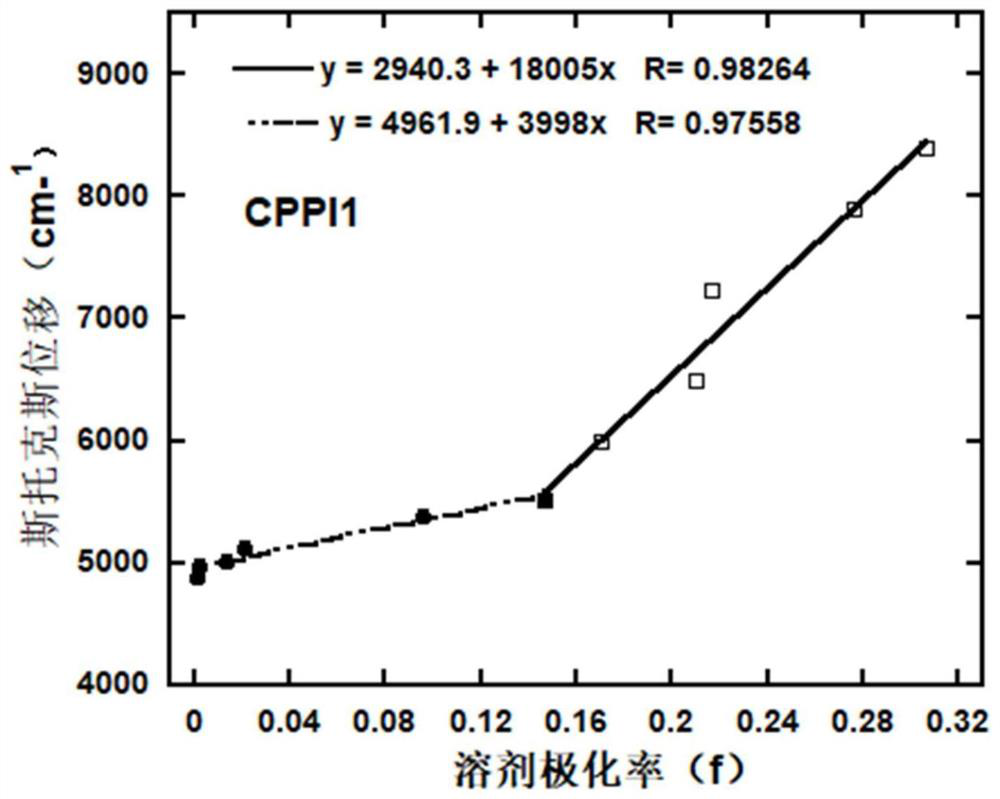

[0086] (5) Preparation of Compound CPPI1

[0087] In argon atmosphere, 2-fluorobenzene [b] naphthalene [2, 1-E: 1 ', 2'-g] [1,4] dioxus (1.89 g, 5 mmol) and 1- ( 4-tert-butylphenyl) -2- (4- (4, 4,4,5,5-tetramethyl-1,3,2-dioxane-2-yl) phenyl) -1H-Philippine [9, 10-D] Imidazole (4.26 g, 7.5 mmol), catalyst tetraphenylphosphine palladium (PD (PPH) 3 ) 4(0.29 g, 0.25 mmol) is dissolved in toluene, and then the potassium carbonate solution (50%, 3.45 g / 3.45 mL deionized water, 25 mmol), 100 ° C reaction for 16 h, stopped the reaction, and quenched with water The reaction was carried out with dichloromethane and dried with anhydrous magnesium sulfate. The solution was concentrated, and the soil yellow liquid was purified, purified, petroleum ether and dichloromethane mixed solvent (volume ratio 3: 1) as a collapse For the eluge, a white solid was obtained, and the yield was 72%. 1 H NMR, 13 C NMR, MS and element analysis results show that the resulting compound is a target product, an...

Embodiment example 18

[0108] Preparation of organic electroluminescent devices

[0109] 1) Cleaning of ITO conductive glass. Place the ITO glass substrate on the washing frame, using ultrasonic ultrasonic cleaning, the sequential sequence of washing liquid is acetone, isopropanol, detergent, deionized water, and isopropyl alcohol, the purpose is to sufficiently remove the ITO glass base Substatic stains such as photoresist, such as photoresist, etc., and improve interface contact. Then dry in a vacuum oven;

[0110] 2) Place ITO in an ion etch analyzer, use oxygen plasma (O 2 Plasma) For twenty-minute bombardment, completely remove the possible residual organic substances of the ITO glass substrate;

[0111] 3) Co-coated 40 nm thick hole injection layer PEDOT: PSS (Baytron P4083) on ITO, and then dried in a vacuum oven at 80 ° C for 12 hours;

[0112] 4) In the glove box of the nitrogen atmosphere, a layer of 80 nm thick with a layer of 80 nm thick, a layer of 80 nm thick, and a device based on the lig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com