Synthesis method of silane hybrid organic silicon resin emulsion

A technology of resin emulsion and synthesis method, which is applied in coatings, anti-corrosion coatings, fire-proof coatings, etc., and can solve the problems of poor storage stability of silicone resin emulsions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

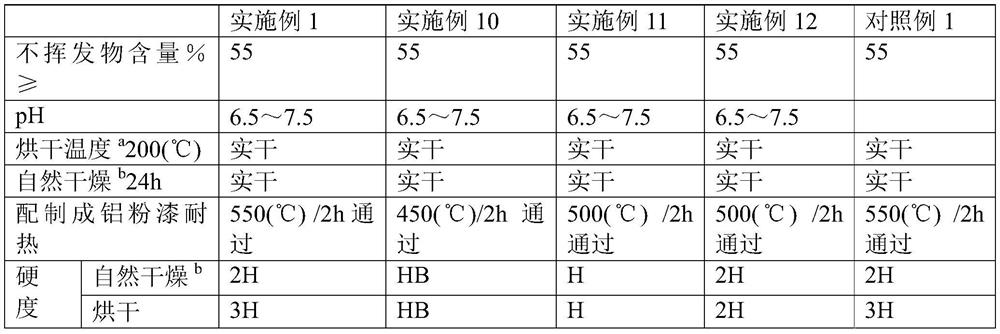

Embodiment 1

[0018] (1) The synthesis method of silicone prepolymer is as follows: the raw materials for synthetic silicone resin: 120 parts of monomethyltrichlorosilane (M1), 80 parts of dimethyldichlorosilane (M2), 1 phenyl trichlorosilane 80 parts of silane (P1), 120 parts of diphenyldichlorosilane (P2), and 120 parts of methylvinyl dichlorosilane were fully mixed in proportion and then added to 600 parts of xylene, 1200 parts of butanol and 600 parts of water were added, The hydrolysis temperature is controlled at 5°C, the hydrolysis is completed in 5 hours, the water is washed to pH ≈ 7, and the solvent is removed by pumping to obtain a silicone resin prepolymer.

[0019] (2) Add 100 parts of silicone prepolymer into the reaction kettle, then add 50 parts of ethylene glycol butyl ether and 50 parts of n-butanol, then raise the temperature to 60°C, and then add 32.5 parts of vinyltrimethoxy Silane, after dripping and keeping warm for 1 hour, vacuumize and desolventize to obtain a silan...

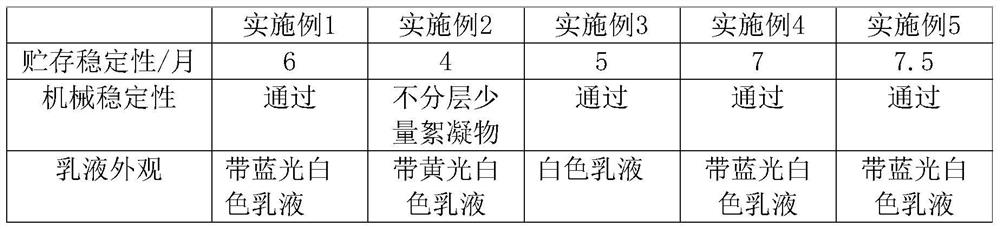

Embodiment 2

[0026] The amount of 2-acrylamido-2-methylpropanesulfonic acid in this example is 8 parts, and the rest are the same as in Example 1.

Embodiment 3

[0028] The amount of 2-acrylamido-2-methylpropanesulfonic acid in this example is 11 parts, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com