PCL/PLA composite foaming oil absorption material and preparation method thereof

A technology of composite foaming and oil-absorbing materials, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve problems such as inability to achieve fast and efficient oil absorption, low mechanical strength of film materials, and inability to be recycled multiple times. Achieve the effects of increasing the nucleation rate and the uniformity of the nucleation point, avoiding the cavitation effect, and increasing the foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

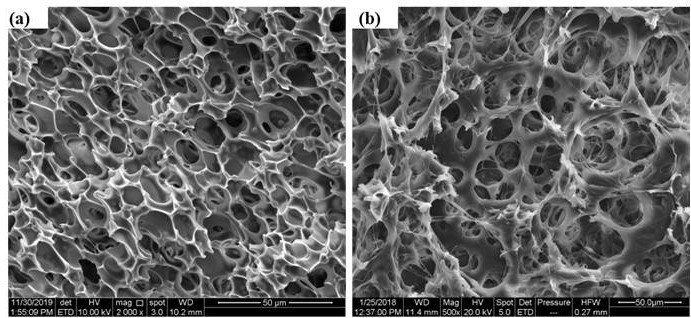

[0038] Embodiment 1: The preparation method of PCL / PLA composite foam oil-absorbing material

[0039] The preparation method of PCL / PLA composite foaming oil-absorbing material comprises the following steps:

[0040] (1) PCL and PLA are melt blended to make a thin plate

[0041] With the PCL (number average molecular weight 50000) of 68wt%, the PLA (weight average molecular weight 210000) of 30wt%, the antioxidant 1010 of 0.5wt%, the lubricating agent polytetrafluoroethylene of 1.0wt%, the antihydrolysis agent of 0.5wt% Bio Adimide 100 was melt blended and granulated on a twin-screw extruder to obtain PCL / PLA blended particles; the PCL / PLA blended particles were placed on a vacuum hot press, and the temperature and pressure were respectively 100 ° C and 1200 psi Under the condition of hot pressing for 5 minutes, the PCL / PLA blended particles were prepared into thin plates with length, width and height of 300mm, 200mm and 1mm respectively.

[0042] (2) High temperature pretre...

Embodiment 2

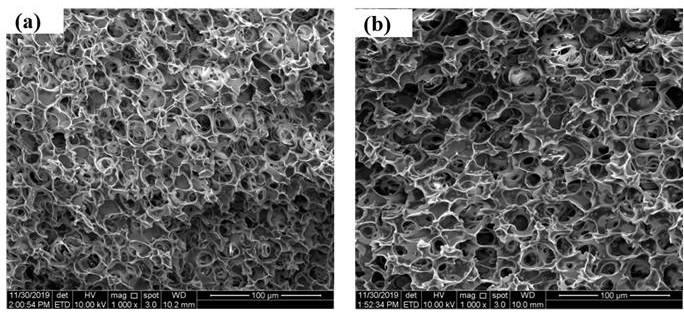

[0052] Example 2: Effect of high temperature pretreatment before saturation on the performance of PCL / PLA composite foamed oil-absorbing material

[0053] 1. Specimen Preparation

[0054] Sample 1: The PCL / PLA composite foamed oil-absorbing material prepared with reference to the steps (1) to (6) of the method described in Example 1, wherein the temperature of the high-temperature pretreatment in step (2) is 80°C, recorded as Sample 1.

[0055] Control Sample 1: The only difference between Control Sample 1 and Sample 1 in the preparation process is that Control Sample 1 has not undergone the high-temperature pretreatment process before step (2) saturation in Example 1. Specifically: the thin plate is prepared with reference to step (1) in Example 1. In step (3), the mold temperature is raised to 40° C., and 2000 psi of supercritical CO is introduced. 2 Saturation 1.0h, forming PCL / PLA polymer and CO 2 For the homogeneous system, the PCL / PLA composite foam oil-absorbing mate...

Embodiment 3

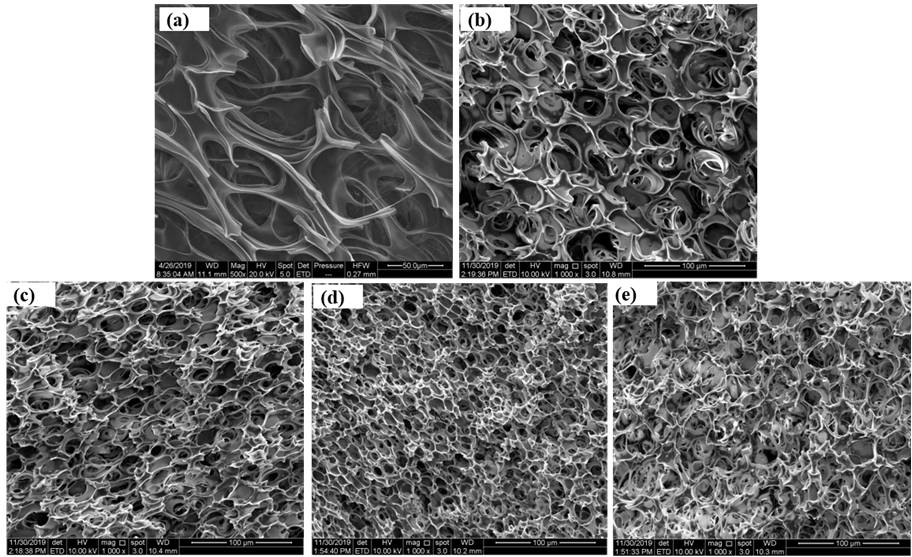

[0078] Embodiment 3: the impact of ultrasonic treatment in different stages on the performance of PCL / PLA composite foam material

[0079] 1. Specimen Preparation

[0080] 1) Sample 2

[0081]With 78wt% PCL (number average molecular weight 50000), 20wt% PLA (weight average molecular weight 210000), 0.5wt% antioxidant 1010, 1.0wt% lubricant polytetrafluoroethylene, 0.5wt% antihydrolysis agent Bio Adimide 100 was used as the raw material, and the PCL / PLA composite foamed oil-absorbing material sample prepared by referring to the preparation method in Example 1 was designated as sample 2. That is, during the preparation process of sample 2, the ultrasound only acts on the stage after saturation and before pressure release.

[0082] 2) Control sample 2

[0083] The preparation raw material of control sample 2 is the same as sample 2, also with reference to the preparation method given in Example 1, but ultrasonic treatment acts on step (4) and step (5) in the preparation proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com