A kind of nitrogen-doped phosphorene quantum dot and preparation method thereof

A nitrogen-doped, quantum dot technology, applied in the field of phosphorene quantum dots, can solve the problems of easy agglomeration and difficult dispersion of materials, and achieve the effects of easy dispersion, high water solubility, and avoidance of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

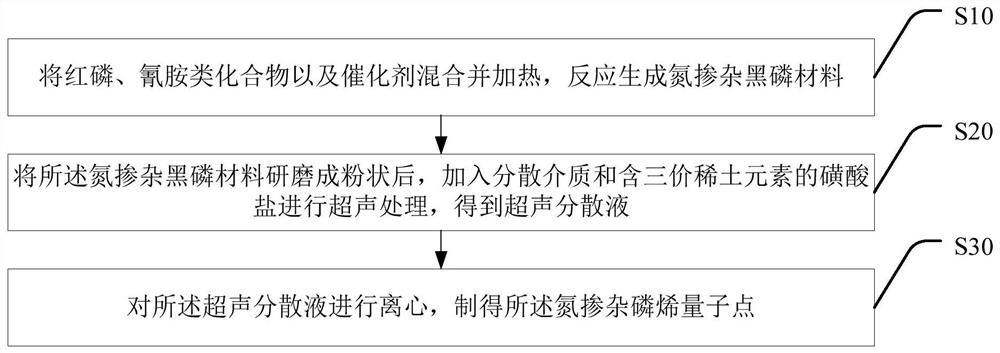

Method used

Image

Examples

Embodiment 1

[0039] (1) Preparation of nitrogen-doped black phosphorus material:

[0040] Blend 10g of red phosphorus, 2g of dicyandiamide, and 1g of tin iodide evenly, place them in a tubular muffle furnace, pass in argon as a protective gas, and increase the temperature of the furnace body at a heating rate of 1.5°C / min. Raised to 600 ° C, and constant temperature reaction for 3h. Then, the heating is stopped, and the furnace body is naturally lowered to room temperature, and the reaction product nitrogen-doped black phosphorus material is taken out.

[0041] (2) Preparation of nitrogen-doped phosphorene quantum dot materials:

[0042] Grind the nitrogen-doped black phosphorus material prepared in (1), and screen the powder with a particle size of 200 mesh, weigh 1g and place it in a 200mL beaker, add 100mL N-methylpyrrolidone as the dispersion medium, 0.1 g of europium trifluoromethanesulfonate was used as a stabilizer to obtain a mixed solution. The mixed solution was placed in an u...

Embodiment 2

[0046] (1) Preparation of nitrogen-doped black phosphorus material:

[0047] Blend 10g of red phosphorus, 2g of melamine, and 1g of tin iodide evenly, place them in a tubular muffle furnace, pass in argon as a protective gas, and raise the temperature of the furnace body at a heating rate of 1.5°C / min to 600°C, and keep the temperature constant for 3h. Then, the heating is stopped, and the furnace body is naturally lowered to room temperature, and the reaction product nitrogen-doped black phosphorus material is taken out.

[0048] (2) Preparation of nitrogen-doped phosphorene quantum dot materials:

[0049] Grind the nitrogen-doped black phosphorus material prepared in (1), and screen the powder with a particle size of 200 mesh, weigh 1g and place it in a 200mL beaker, add 100mL N-methylpyrrolidone as the dispersion medium, 0.1 g of europium trifluoromethanesulfonate was used as a stabilizer to obtain a mixed solution. The mixed solution was placed in an ultrasonic disperse...

Embodiment 3

[0053] (1) Preparation of nitrogen-doped black phosphorus material:

[0054] Blend 10g of red phosphorus, 2g of dicyandiamide, and 1g of tin iodide evenly, place them in a tubular muffle furnace, pass in argon as a protective gas, and increase the temperature of the furnace body at a heating rate of 1.5°C / min. Rise to 600 ° C, and keep the temperature for 3h. Then, the heating is stopped, and the furnace body is naturally lowered to room temperature, and the reaction product nitrogen-doped black phosphorus material is taken out.

[0055] (2) Preparation of nitrogen-doped phosphorene quantum dot materials:

[0056] Grind the nitrogen-doped black phosphorus material prepared in (1), and screen the powder with a particle size of 200 mesh, weigh 1g and place it in a 200mL beaker, add 100mL N-cyclohexylpyrrolidone in turn as the dispersion medium, 0.1 g of europium trifluoromethanesulfonate was used as a stabilizer to obtain a mixed solution. The mixed solution was placed in an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com