Ultra-small cobalt sulfide nanosheet/carbon cloth composite material and preparation method thereof

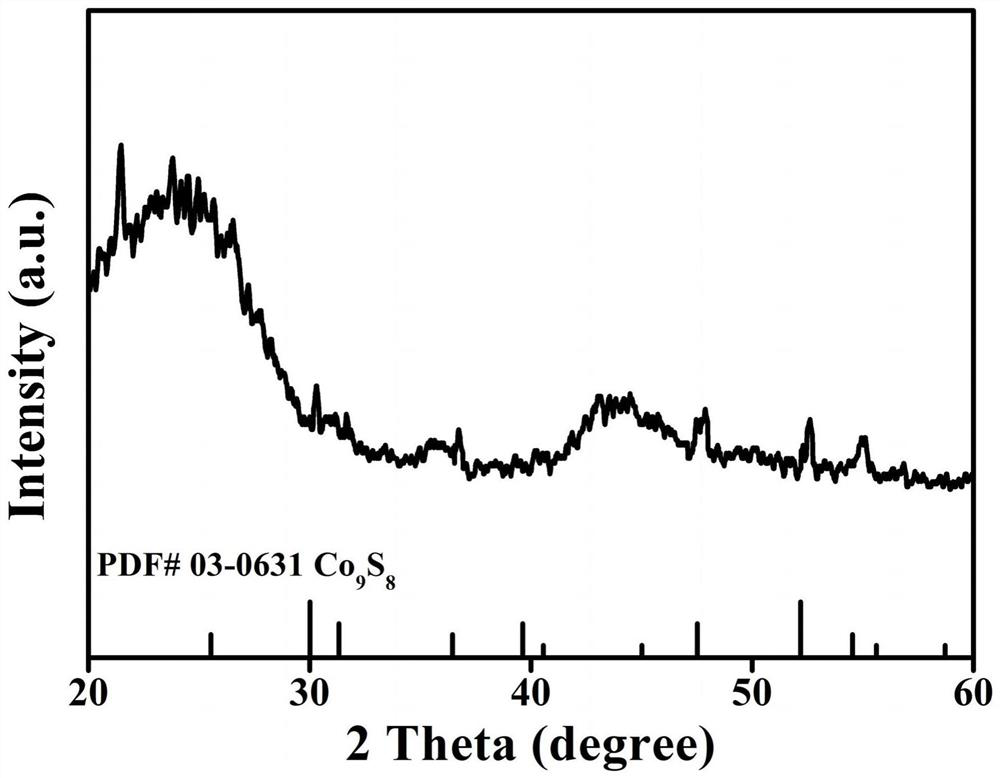

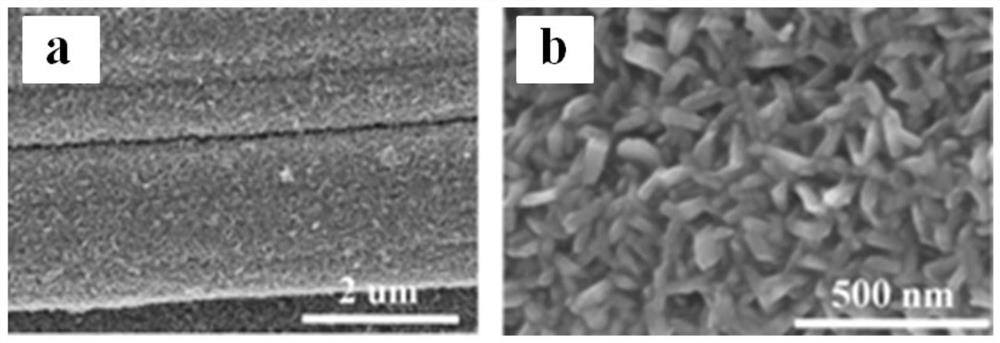

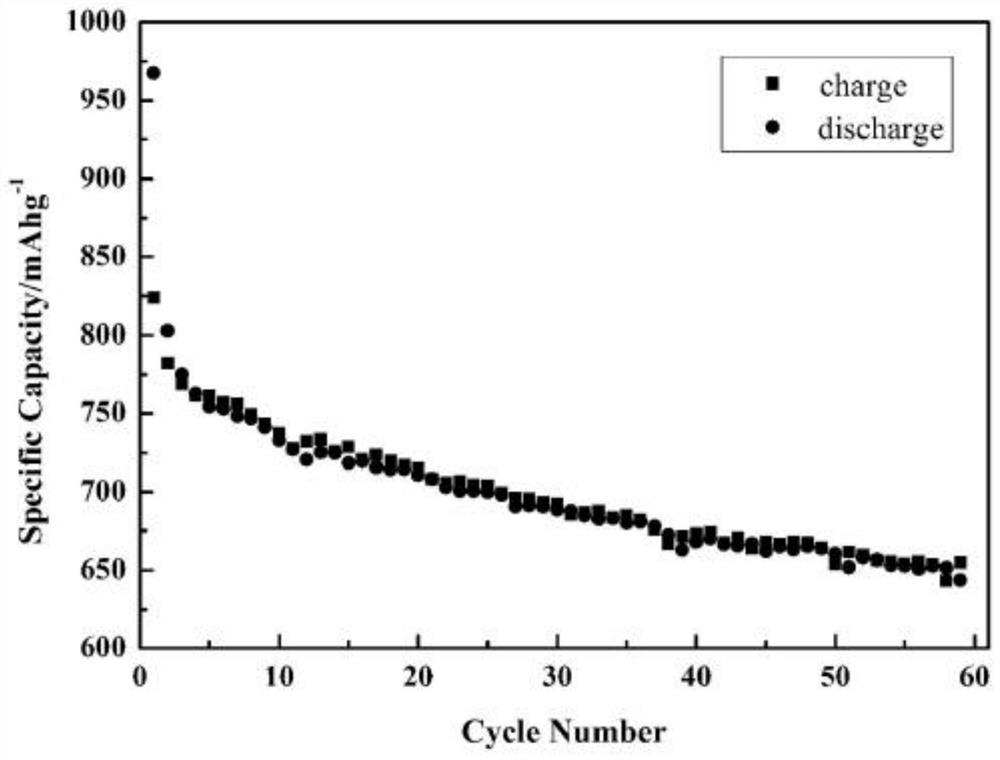

A composite material, cobalt sulfide technology, applied in the field of electrochemistry, can solve problems such as poor cycle performance, electrode pulverization, and poor rate performance, and achieve the effects of low cost, improved conductivity, and increased capacity contribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Take a certain amount of analytically pure cobalt acetate, tetrahydrate and sulfur powder and join together in the ethanol solution, and stir to obtain a clear solution A. The concentration of cobalt acetate is 0.15mol / L, and the mass ratio of cobalt acetate and sulfur powder is 1:0.7;

[0027] 2) Put the clear solution A at room temperature and avoid light for 4 hours, perform suction filtration, collect the powder and wash it alternately with deionized water and absolute ethanol for 3-5 times, and dry it in a vacuum drying oven at 70°C for 5 hours. Obtain powder A;

[0028] 3) Cut the carbon cloth into a size of 2cm*3cm, completely soak it in concentrated nitric acid solution, and react it in an oven at 90°C for 2 hours. Handle carbon cloth;

[0029] 4) Place the pretreated carbon cloth and powder A at both ends of the magnetic state respectively, put them together into a tube furnace, and calcinate to 700°C under the protection of an argon atmosphere, with a hea...

Embodiment 2

[0031] 1) Take a certain amount of analytically pure cobalt acetate, tetrahydrate and sulfur powder and join together in the ethanol solution, and stir to obtain a clear solution A. The concentration of cobalt acetate is 0.18mol / L, and the mass ratio of cobalt acetate and sulfur powder is 1:0.9;

[0032] 2) Put the clear solution A at room temperature and avoid light for 5 hours, perform suction filtration, collect the powder and wash it alternately with deionized water and absolute ethanol for 3-5 times, and dry it in a vacuum oven at 70°C for 8 hours. Obtain powder A;

[0033] 3) Cut the carbon cloth into a size of 2cm*3cm, completely soak it in concentrated nitric acid solution, and react it in an oven at 90°C for 3 hours. Handle carbon cloth;

[0034] 4) Place the pretreated carbon cloth and powder A at both ends of the magnetic state respectively, put them together into a tube furnace, and calcinate to 750°C under the protection of argon atmosphere, with a heating rate ...

Embodiment 3

[0036] 1) Take a certain amount of analytically pure cobalt acetate, tetrahydrate and sulfur powder and join together in the ethanol solution, and stir to obtain a clear solution A. The concentration of cobalt acetate is 0.2mol / L, and the mass ratio of cobalt acetate and sulfur powder is 1:1.1;

[0037] 2) Put the clear solution A at room temperature and avoid light for 7 hours, perform suction filtration, collect the powder and wash it alternately with deionized water and absolute ethanol for 3-5 times, and dry it in a vacuum drying oven at 70°C for 10 hours. Obtain powder A;

[0038] 3) Cut the carbon cloth into a size of 2cm*3cm, completely soak it in concentrated nitric acid solution, and react it in an oven at 90°C for 4 hours. Handle carbon cloth;

[0039] 4) Place the pretreated carbon cloth and powder A at both ends of the magnetic state, put them together into a tube furnace, and calcinate to 800°C under the protection of an argon atmosphere, with a heating rate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com