Transparent water-impact-resistant super-lyophobic coating as well as preparation method and application of transparent water-impact-resistant super-lyophobic coating

A super-lyophobic and coating technology, applied in coatings, primers, etc., can solve the problems of haze influence, unexplained wear resistance and weather resistance, water impact resistance, and reduced mechanical stability, so as to achieve low cost and suitable The effect of large-scale production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] First, prepare the primer solution: dissolve 0.63g of ethylene acrylic acid copolymer (20wt% acrylic acid content) in tetrahydrofuran (30mL) and butyl acetate (60mL), stir until completely dissolved, and store for use;

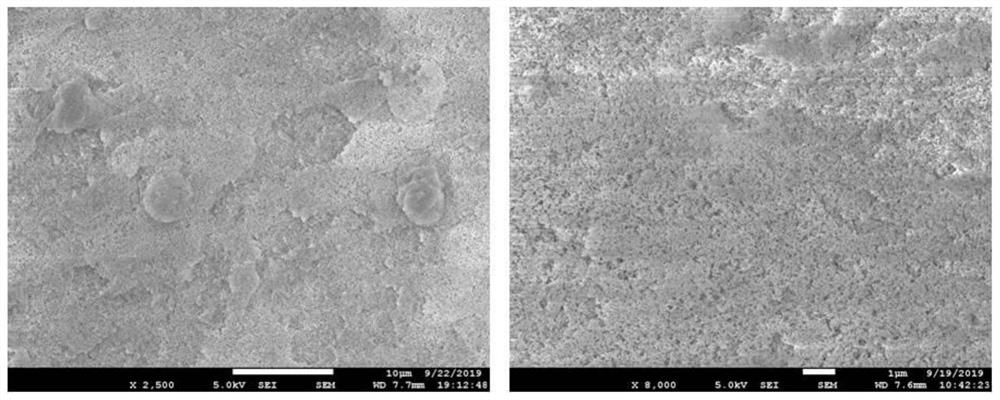

[0070] Next, prepare the topcoat solution: disperse 1 g of hydrophobic fumed nano-silica in isopropanol (100 mL) by ultrasonication for 30 minutes (ultrasonic power 650 W) to obtain a bluish transparent dispersion, and the secondary particles of nano-silica before ultrasonication The diameter is more than 500nm, and most of them are micron-scale aggregates. After ultrasonication, the secondary particle size is reduced to less than 200nm, and it is stored for use;

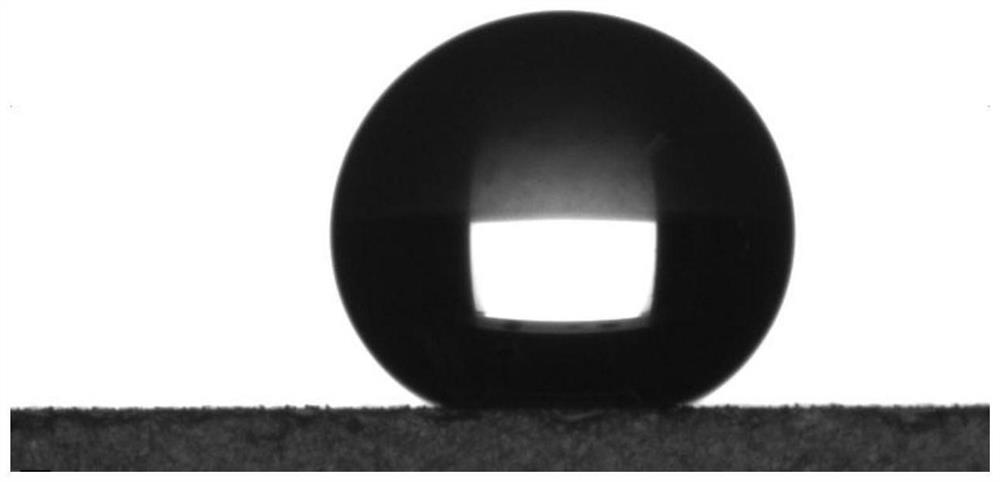

[0071] Finally, the coating is prepared by spraying: the primer solution is sprayed on the surface of the glass substrate to form a thin film. The spraying pass is 30 times, and the spraying thickness is within 100nm. The spraying process is controlled to ensure that the film is transparent, a...

Embodiment 2

[0077] First, prepare the primer solution: dissolve 0.63g of acrylic resin in butyl acetate (90mL), stir until completely dissolved, and store for use;

[0078]Next, prepare the topcoat solution: disperse 1 g of hydrophobic fumed nano-silica in isopropanol (100 mL) by ultrasonication for 30 minutes (ultrasonic power 650 W) to obtain a bluish transparent dispersion, and the secondary particles of nano-silica before ultrasonication The diameter is more than 500nm, and most of them are micron-scale aggregates. After ultrasonication, the secondary particle size is reduced to less than 200nm, and it is stored for use;

[0079] Finally, the coating is prepared by spraying: the primer solution is sprayed on the surface of the glass substrate to form a thin film. The spraying pass is 15 times, and the spraying thickness is within 50nm. The spraying process is controlled to ensure that the film is transparent, and the first coating is obtained. Then spray the topcoat liquid on the surf...

Embodiment 3

[0083] First, prepare the primer solution: dissolve 0.63 g of butyl acetate cellulose in butyl acetate (90 mL), stir until completely dissolved, and store for use;

[0084] Next, prepare the topcoat solution: disperse 1 g of hydrophobic fumed nano-silica in isopropanol (100 mL) by ultrasonication for 30 minutes (ultrasonic power 650 W) to obtain a bluish transparent dispersion, and the secondary particles of nano-silica before ultrasonication The diameter is more than 500nm, and most of them are micron-scale aggregates. After ultrasonication, the secondary particle size is reduced to less than 200nm, and it is stored for use;

[0085] Finally, the coating is prepared by spraying: the primer solution is sprayed on the surface of the glass substrate to form a thin film. The spraying pass is 30 times, and the spraying thickness is within 100nm. The spraying process is controlled to ensure that the film is transparent, and the first coating is obtained. Then spray the topcoat liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com