Preparation method of high-stability thermally-induced flexible phase change material and cushioning battery module

A high-stability, phase-change material technology, used in heat-exchange materials, battery pack components, secondary batteries, etc., can solve the problems of poor uniformity, easy leakage, and poor thermal conductivity of phase-change materials. Effects of improved uniformity, improved thermal conductivity, lightweight and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

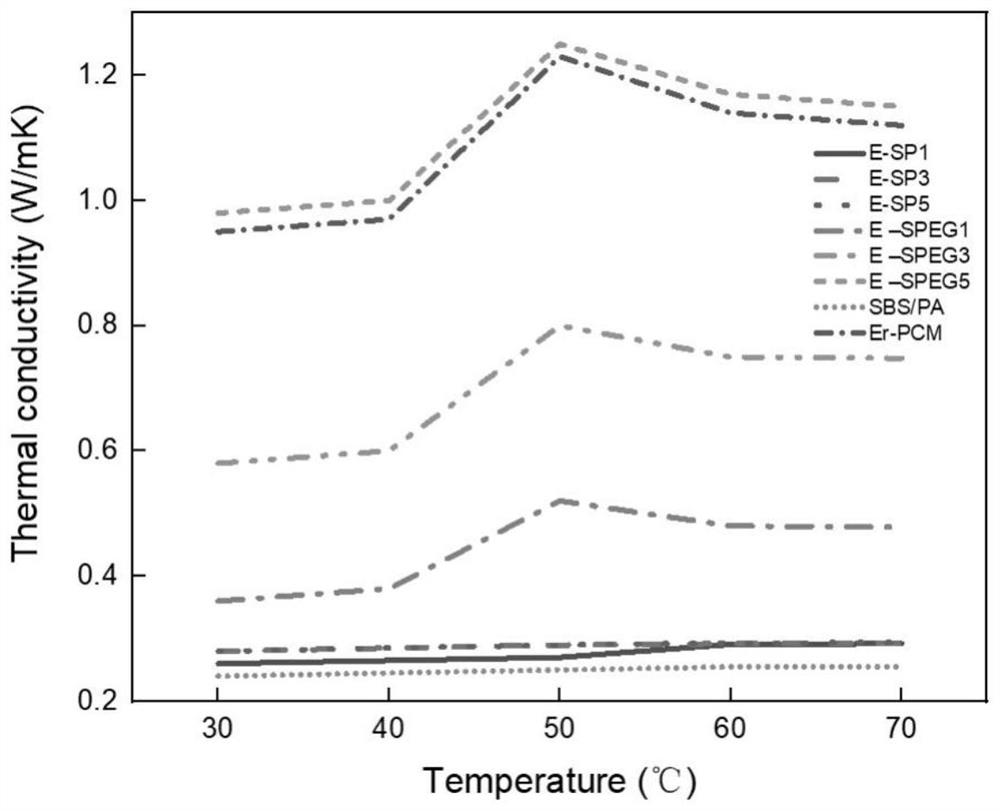

[0037] (1) Melt the paraffin at 150°C, add styrene-butadiene-styrene block copolymer and stir and dissolve at 500rad / min to obtain a translucent colloidal solution;

[0038] (2) Add EPDM rubber (ethylene, propylene and non-conjugated diene terpolymer, molecular weight distribution: 2 to 5) into the translucent colloidal solution and stir and melt at 1000rad / min, wherein paraffin, The mass ratio of styrene-butadiene-styrene block copolymer and EPDM rubber is 8:1:0.5 to obtain a viscous colloidal solution;

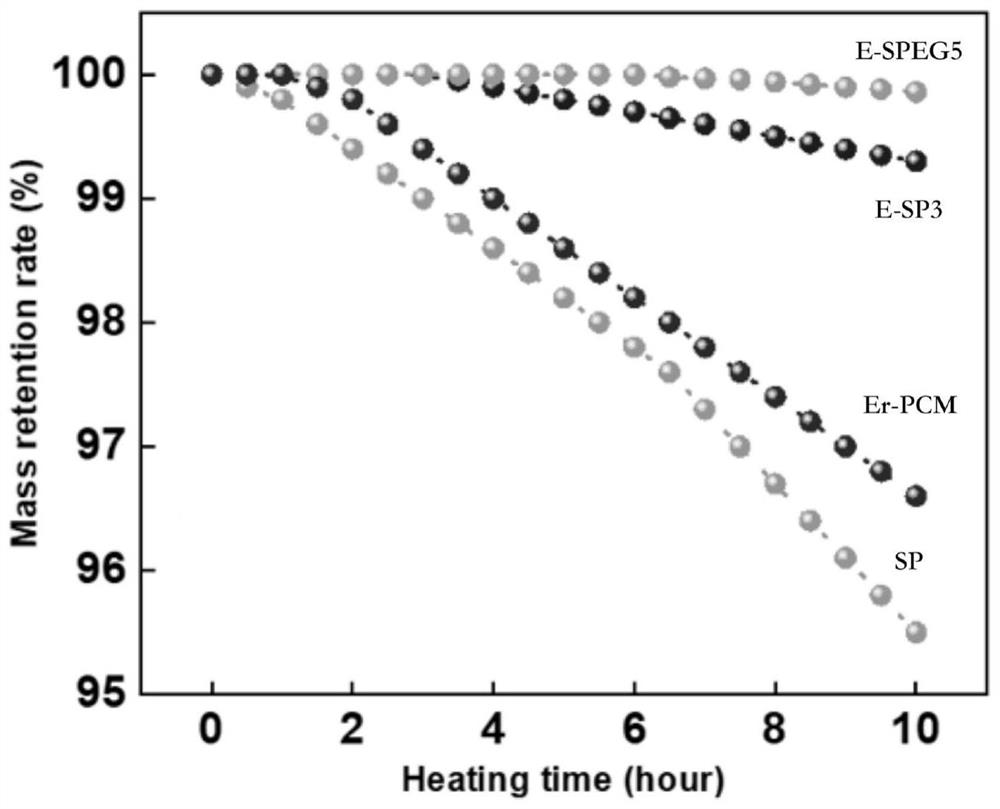

[0039] (3) adding expanded graphite in the viscous colloidal solution and stirring and mixing at 1000rad / min, wherein the addition of the thermal conductivity enhancer is respectively 1wt%, 3wt% and 5wt% of the total mass, poured into the mold for curing, The products E-SPEG1, E-SPEG3 and E-SPEG5 were prepared respectively.

Embodiment 2

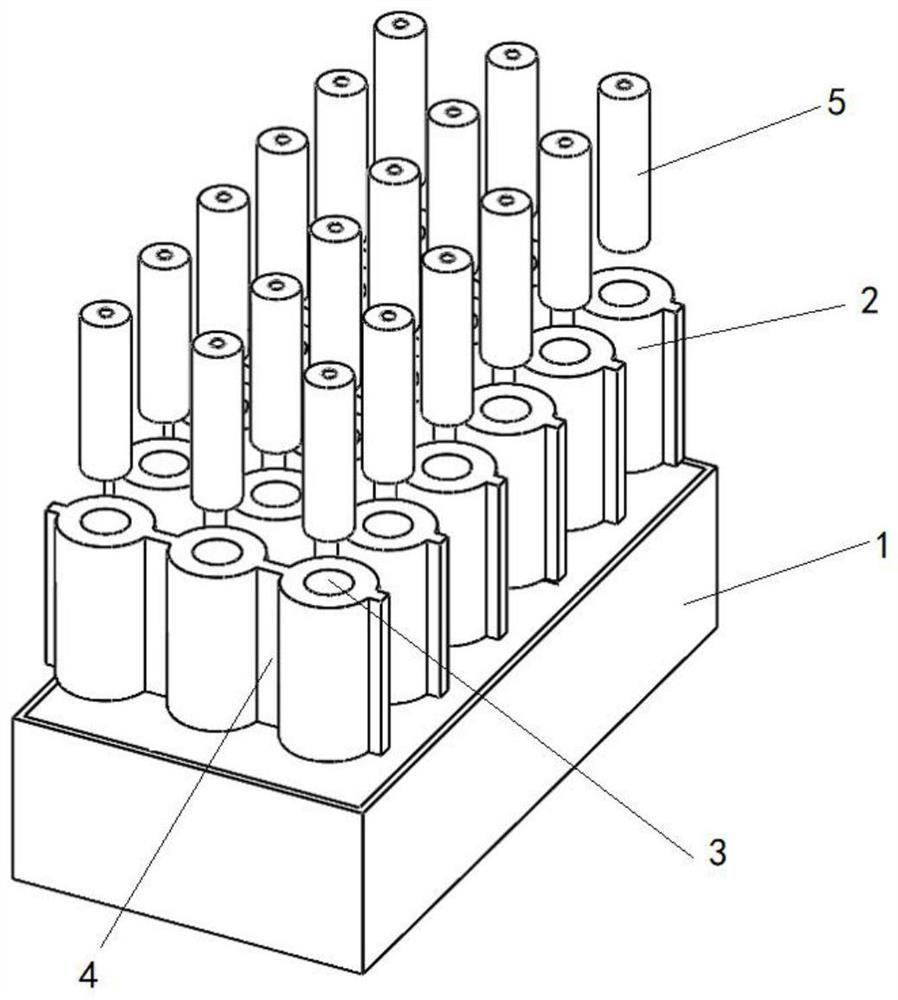

[0052] Please refer to Figure 3-4 , the embodiment of the present application provides a cushioning battery 5 module, including a box body 1 and a battery bracket; the battery bracket is placed in the box body 1, and is used to load the battery 5; the battery bracket is made of the product obtained in Example 1 .

[0053] In the embodiment of the present application, the phase change material has good flexibility, and it still has a high quality retention rate after long-term use at high temperature, which can realize the lightweight and compactness of the battery 5 module, and improve the thermal conductivity of the phase change material , more effectively adapt to the thermal management of the battery 5, and avoid the problem of being out of thermal contact with the battery 5 during leakage and vibration. It should be noted that the box body 1 is made of insulating material.

[0054] Further, the battery holder includes a loading cylinder 2 and a connecting member 4 conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com