Ruthenium and nitrogen co-doped porous carbon catalyst, preparation method thereof and application of ruthenium and nitrogen co-doped porous carbon catalyst in hydrogen evolution by electrolysis

A co-doping and catalyst technology, applied in the field of electrochemistry, can solve problems such as shedding and aggregation, and achieve the effect of improving stability, good repeatability and large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

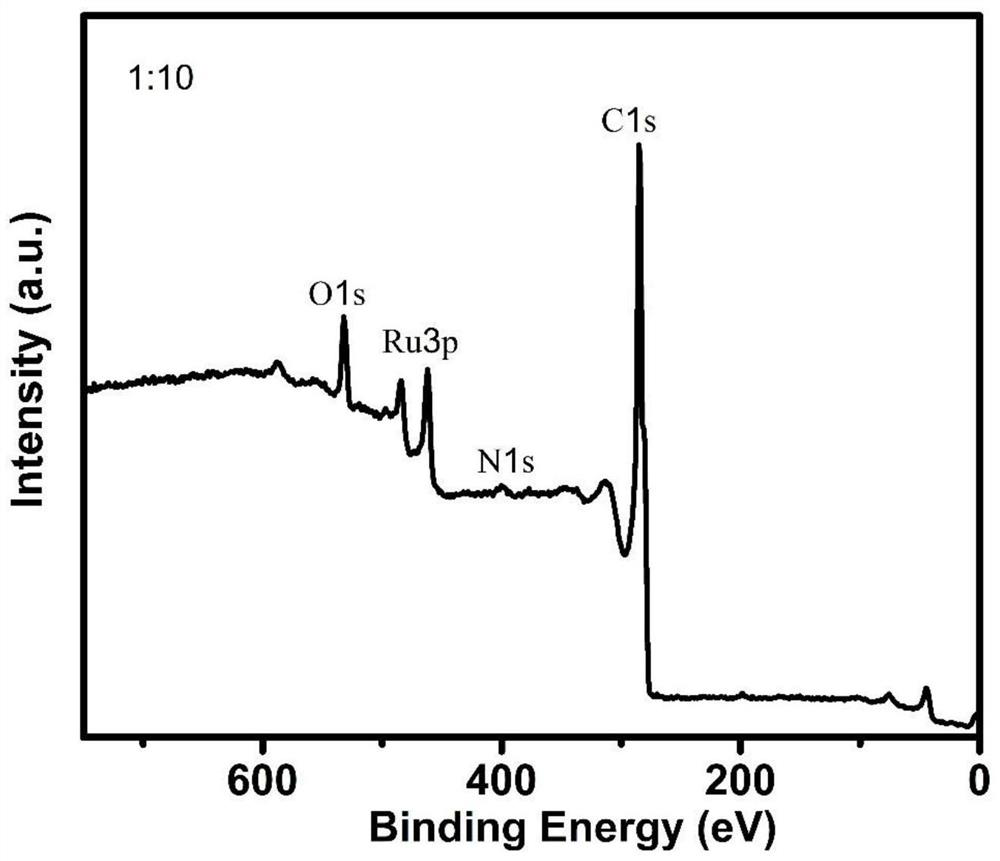

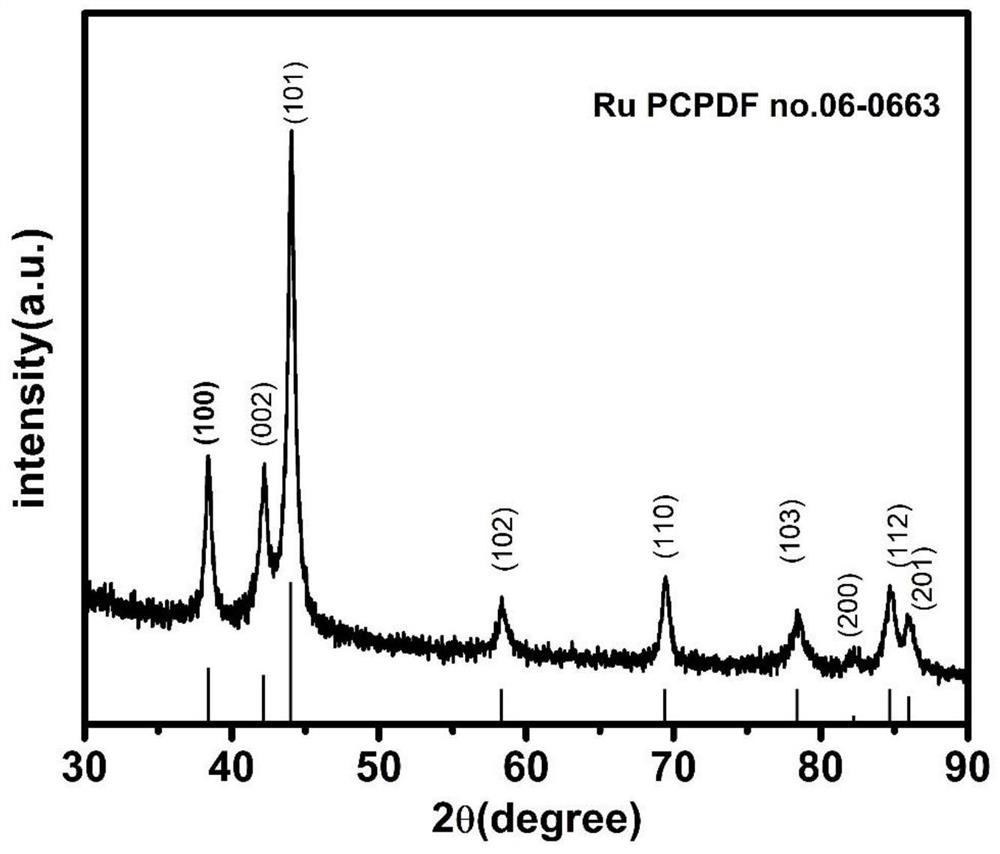

[0030] (1) In 10 mL of water, add 20.7 mg (1 mmol) of ruthenium trichloride and 452 mg (10 mmol) of tetrasodium ethylenediaminetetraacetic acid tetrahydrate respectively, ultrasonically dissolve at room temperature, and then stir for 0.5 h. The solvent of the reaction solution was completely evaporated by a rotary evaporator, and finally the remaining solid was vacuum-dried in a vacuum oven at 60° C. for 12 hours to obtain a ruthenium complex precursor.

[0031] (2) Under the protection of the inert gas argon, the precursor obtained in step (1) was placed in a tube furnace and heated to 850° at a rate of 5°C / min, pyrolyzed at a constant temperature for 2h, and then naturally cooled to room temperature.

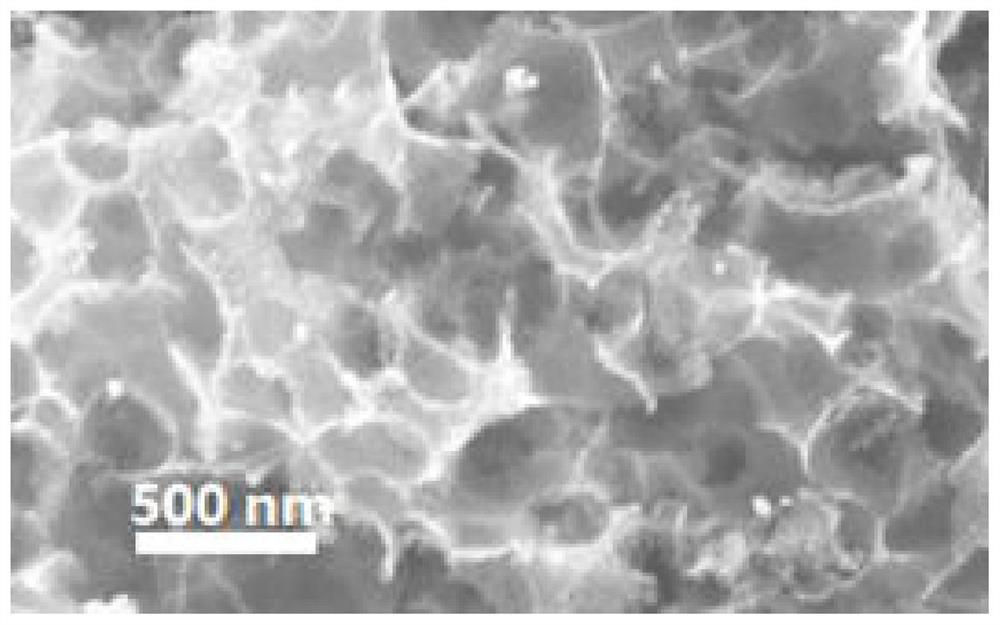

[0032] (3) After the black granular product obtained in step (2) is ground to powder, it is dispersed in 0.5M H 2 SO 4 Stir at room temperature for 12 hours, then wash with deionized water and dry in vacuum to prepare a ruthenium-nitrogen co-doped porous carbon catalyst.

[...

Embodiment 2

[0042] In this example, the ruthenium-doped porous carbon electrocatalyst was prepared according to the same method as in Example 1, except that the amount of tetrasodium ethylenediaminetetraacetic acid tetrahydrate as a raw material in step (1) was changed to 226 mg (5 mmol).

[0043]Electrochemical tests were carried out on the electrocatalyst obtained in this example in the same manner as in Example 1.

[0044] Such as Figure 6 Shown, at room temperature, the catalyst of this embodiment reaches 10mAcm in 1M KOH -2 The current density requires an overpotential of 75mV.

Embodiment 3

[0046] In this example, the ruthenium-doped porous carbon electrocatalyst was prepared according to the same method as in Example 1, except that the amount of tetrasodium ethylenediaminetetraacetic acid tetrahydrate as a raw material in step (1) was changed to 678 mg (15 mmol).

[0047] Electrochemical tests were carried out on the electrocatalyst obtained in this example in the same manner as in Example 1.

[0048] Such as Figure 7 Shown, at room temperature, the catalyst of this embodiment reaches 10mAcm in 1M KOH -2 The current density requires an overpotential of 95mV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com