A high -energy density lithium ion battery electrolyte and its application

A lithium-ion battery, high energy density technology, used in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of cycle performance and safety performance decline, and achieve improved cycle performance, small thickness expansion, improved Effects of Cyclic Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

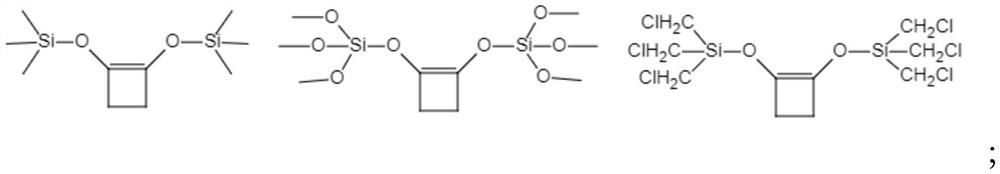

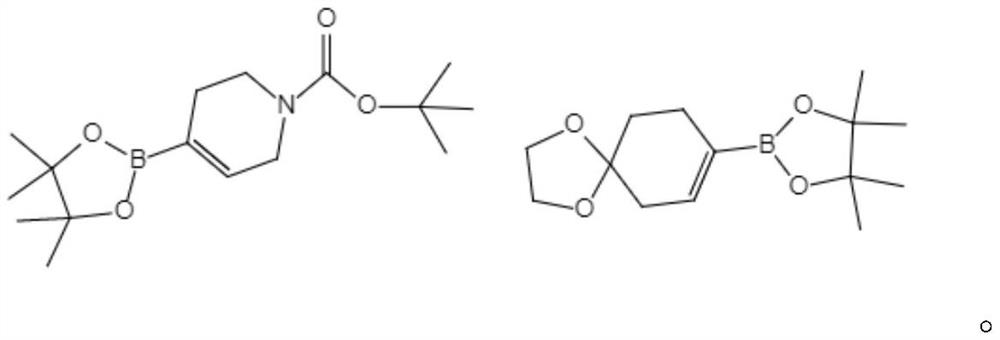

[0033] Under nitrogen airtight protective atmosphere, moisture <10ppm, take the solvent ethylene carbonate (EC), ethyl methyl carbonate (EMC) and diethyl carbonate (DEC) in a mass ratio of 1:1:1 and then add and mix them, using a condenser Cool the mixed solution to ensure that the temperature is not higher than 10 °C, slowly add lithium hexafluorophosphate to ensure that the lithium salt concentration is 1.2 mol / L, and then add 1,3-propane sultone (PS) with a film-forming additive mass fraction of 1.5%. and 1% fluoroethylene carbonate (FEC), finally adding 0.5% bis(trimethylsiloxy)cyclobutene and 2% 1,4-dioxa-spiro[4,5] Dec-7-ene-8-boronic acid pinacol continued to stir until the solution became clear.

Embodiment 2

[0035] The difference from Example 1 is that the amount of functional additives added is different. The mass fraction of 1% bis(trimethylsiloxy)cyclobutene and 2% of 1,4-dioxa-spiro[4,5 ] Dec-7-ene-8-boronic acid pinacol ester and continue stirring until the solution becomes clear.

Embodiment 3

[0037] The difference from Example 1 is that the amount of functional additives added is different. The mass fraction of 1.5% bis(trimethylsiloxy)cyclobutene and 2% of 1,4-dioxa-spiro[4,5 ] Dec-7-ene-8-boronic acid pinacol ester and continue stirring until the solution becomes clear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com