Preparation method of infant formula milk powder

A technology for infant formula and milk powder, applied to milk preparations, bacteria used in food preparation, dairy products, etc., can solve the problems of attenuation, severe, and water activity sensitivity during product storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

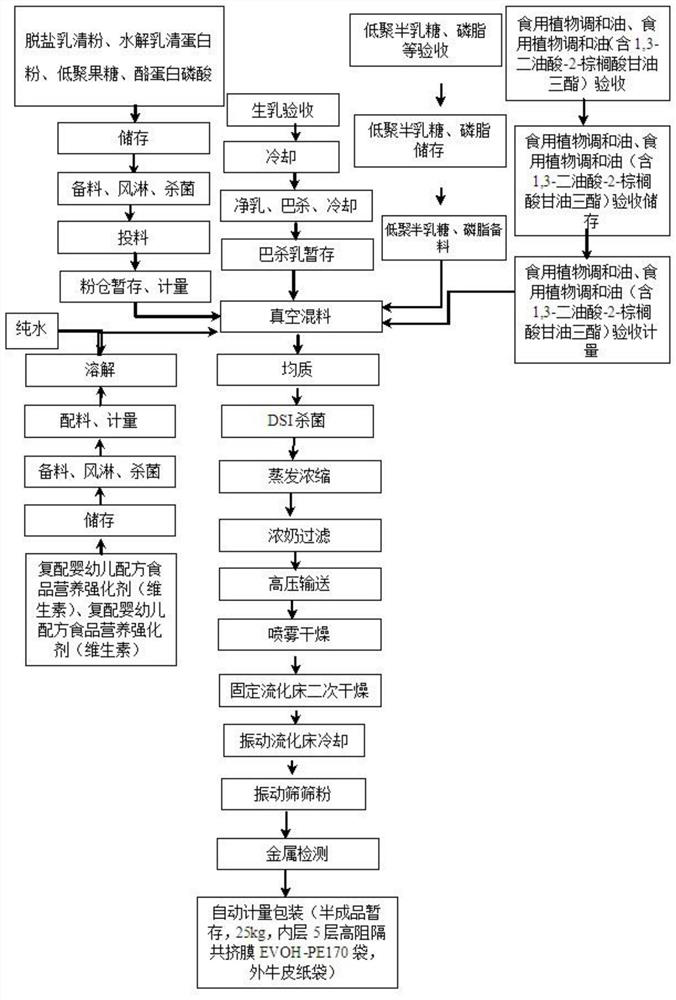

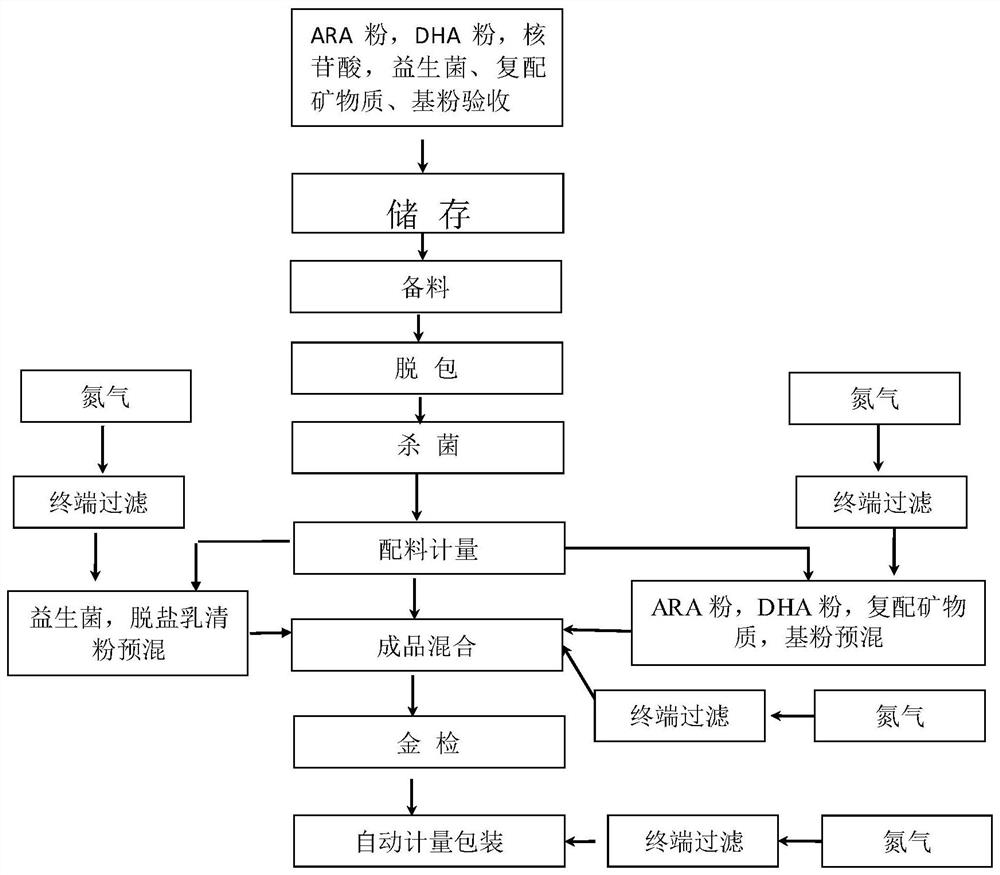

[0035] The invention provides a kind of preparation method of infant formula milk powder, comprises the following steps:

[0036] A) adopting wet process to prepare the base powder with water activity≤0.18;

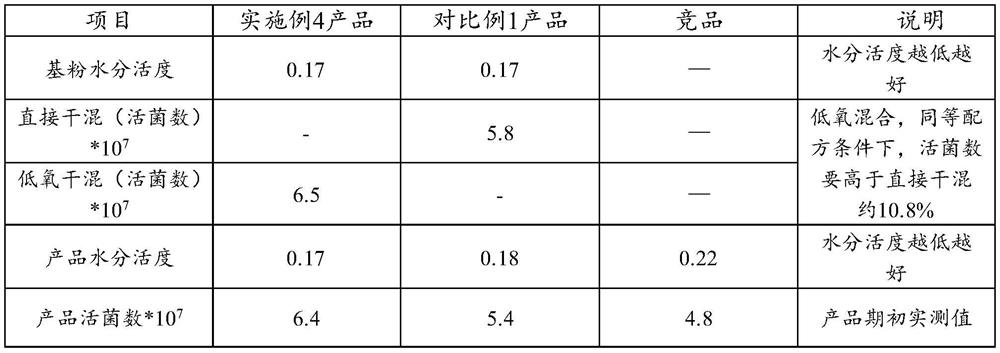

[0037] B) dry mixing the base powder, auxiliary materials and probiotics to obtain formula milk powder for infants and young children, the condition of the dry mixing is to vacuumize and fill with N 2 , Residual oxygen <3%.

[0038] The invention firstly adopts a wet process to prepare the base powder with water activity ≤ 0.18.

[0039] The present invention optimizes the control of the wet process and improves the packaging material. The inner packaging material is 5-layer high-barrier co-extrusion film EVOH-PE170 to package the base powder, so as to ensure that the water activity of the base powder can be controlled below 0.18 before use and mixing.

[0040] Specifically, the base powder is prepared according to the following method:

[0041] 1) Raw milk, purified w...

Embodiment 1

[0116] Embodiment 1 Infant formula milk powder base powder formula and preparation method

[0117] 1. The formula for producing 1 ton of infant formula milk powder base powder is:

[0118] Raw milk 2000kg, lactose 270kg, edible vegetable blend oil (containing 1,3-dioleic-2-palmitic triglyceride) 175kg [1,3-dioleic-2-palmitic triglyceride 82.0kg, vegetable Seed oil 33.0kg, sunflower oil 29.0kg, soybean oil 21.0kg, palm kernel oil 10.0kg], desalted whey powder 175kg, hydrolyzed whey protein powder 56kg, galacto-oligosaccharide 25kg; Oleic acid-2-palmitic acid triglyceride edible vegetable blend oil 25kg [rapeseed oil 9.0kg, corn oil 7.0kg, coconut oil 5.5kg, sunflower oil 3.5kg], fructooligosaccharide 14kg, casein phosphopeptide 2.0 kg, compound infant formula nutrition enhancer 01 (vitamin) 5.0kg, compound infant formula nutrition enhancer 01 (mineral) 16.0kg, phospholipid 4.0kg

[0119] In kilograms by weight, the formula of the compound infant formula food additive 01 (vitami...

Embodiment 2

[0139] Embodiment 2 Larger infant formula milk powder base powder formula

[0140] 1. The formula for producing 1 ton of follow-up infant formula milk powder base powder is:

[0141] Raw milk 2300kg, lactose 50kg, edible vegetable blend oil (containing 1,3-dioleic acid-2-palmitic acid triglyceride) 130kg [1,3-dioleic acid-2-palmitic acid triglyceride 62.0kg, vegetables Seed oil 24.0kg, sunflower oil 23.0kg, soybean oil 16.0kg, palm kernel oil 5.0kg], desalted whey powder 350kg, skimmed milk powder 103kg, hydrolyzed whey protein powder 25kg, galacto-oligosaccharide 25kg; edible plant reconciliation Oil 18kg [rapeseed oil 7.0kg, corn oil 6.0kg, coconut oil 4.0kg, sunflower oil 1.0kg], fructooligosaccharides 14kg, casein phosphopeptide 2.0kg, compound infant formula nutrition enhancer 02 (vitamin ) 3.5kg, compound infant formula nutritional fortifier 02 (mineral) 5.0kg, phospholipid 4.0kg

[0142] In kilograms by weight, the formula of the compound infant formula food additive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com