Biological composite nutritional lick brick and preparation process thereof

A nutrient licking brick and biological technology, applied in the field of biological compound nutrient licking brick and its preparation, can solve the problems of small feed intake, single nutrition, easy to disperse texture, etc., and achieve slow release of elements, comprehensive nutrition, and low feed intake Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be described below, apparent, as described herein is merely embodiments of the invention, not all of the embodiments.

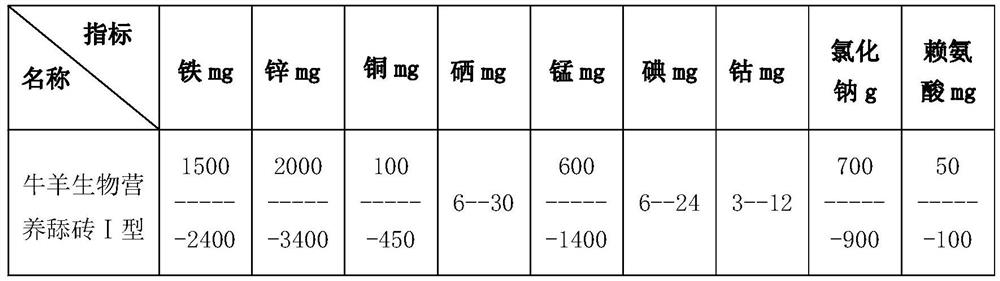

[0024] A bio-composite nutritional tile, the main nutrient guarantee value per kg brick includes: a number of effective live bacteria (composite microbacterial agents with Bacillus Bacillus) ≥ 20 billion, composite amino acid 50-150mg, compound vitamin 0.5- 1.5IU, ferrous sulfate 1500-3000 mg, zinc sulfate 1500-300 mg, copper sulfate 100-450 mg, chloride 400-1000 mg, sodium sulfate, 1-30 mg of selenate, potassium iodide 3-40 mg, chlorine 3-20 mg of cobalt, magnesium oxide 1000-3000 mg, calcium hydrogen phosphate calcium hydrogen phosphate 50-100g, salt 400-750 g, fermented corn pulp 100-200g.

[0025] A bio-composite nutritional tile preparation process, including steps: a, amino acid ferrous acid ferrous sulfate, zinc sulfate, copper sulfate, manganese sulfate, to obtain biological c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com