Method and system for crystallizing and separating fly ash washing liquid and separating and purifying sodium salt and potassium salt based on seed crystal method

A purification method and fly ash technology, which is applied in the direction of crystallization separation, separation methods, chemical instruments and methods, etc., can solve the problems of complex composition of fly ash washing liquid, affecting production efficiency, low heat transfer efficiency, etc., to achieve product value enhancement, Cost saving and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

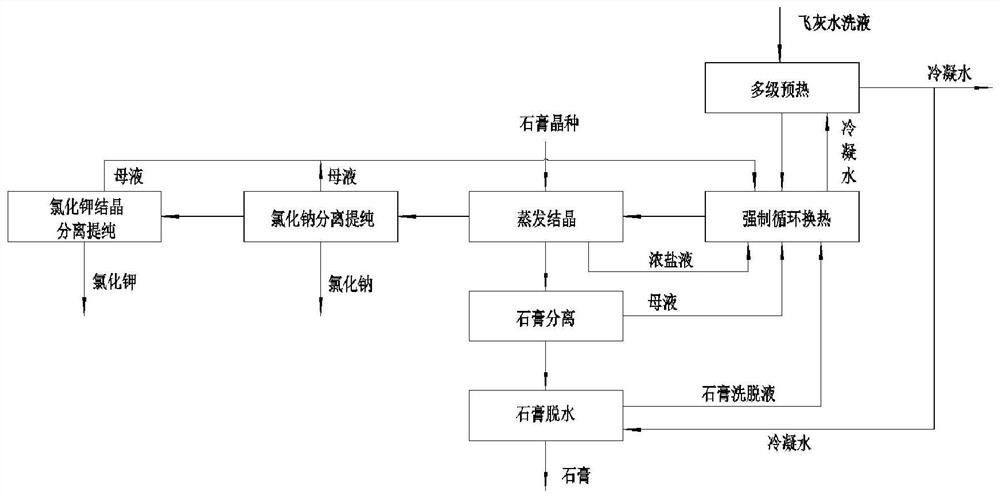

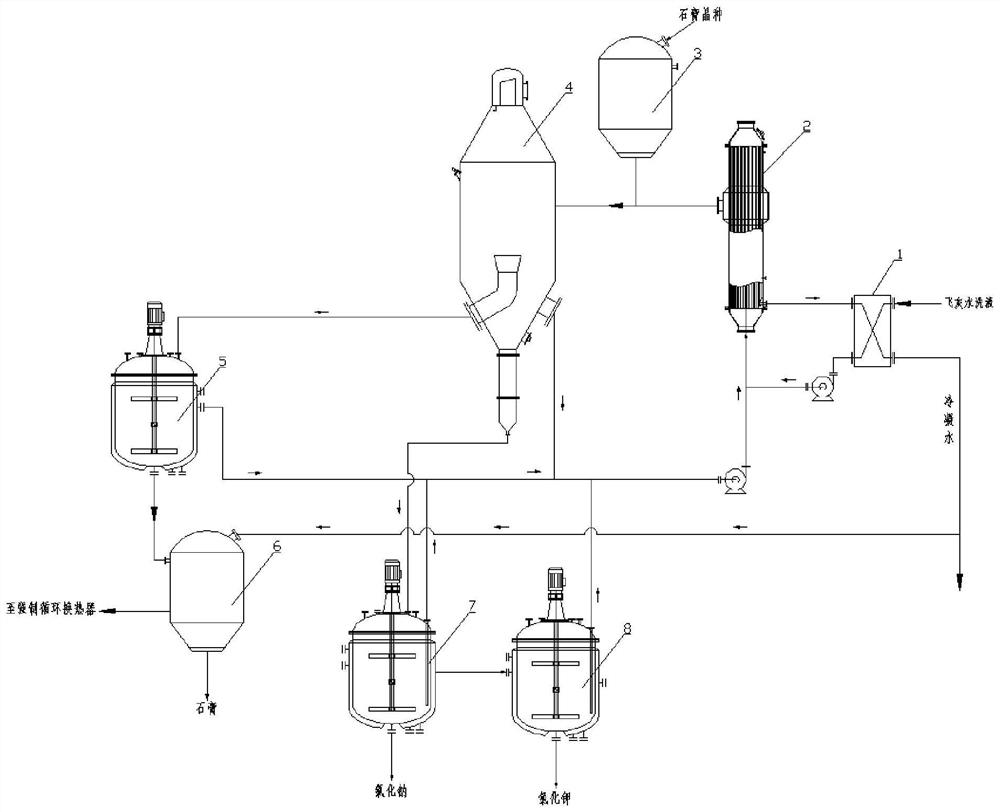

[0062] Example 1 Fly Ash Washing Crystallization Separation System Based on Seed Method and Separation and Purification of Sodium and Potassium Salts

[0063] see figure 1 and image 3 , this embodiment provides a fly ash water washing and crystallization separation system based on the seed crystal method and a separation and purification method for sodium salt and potassium salt, including:

[0064] Step (1) Preheating of the washing liquid: the purified fly ash washing liquid is preheated in the multi-stage preheater 1 to obtain a preheated feed liquid at 90°C-110°C, and the condensation generated during the multistage preheating process The water is used as dechlorination water for the gypsum dehydration unit.

[0065] Step (2) Evaporation and concentration: the preheated feed liquid is pumped into the forced circulation heat exchanger 2 through the feed pipe, and the preheated feed liquid is evaporated and concentrated in the forced circulation heat exchanger 2 to obtain...

Embodiment 2

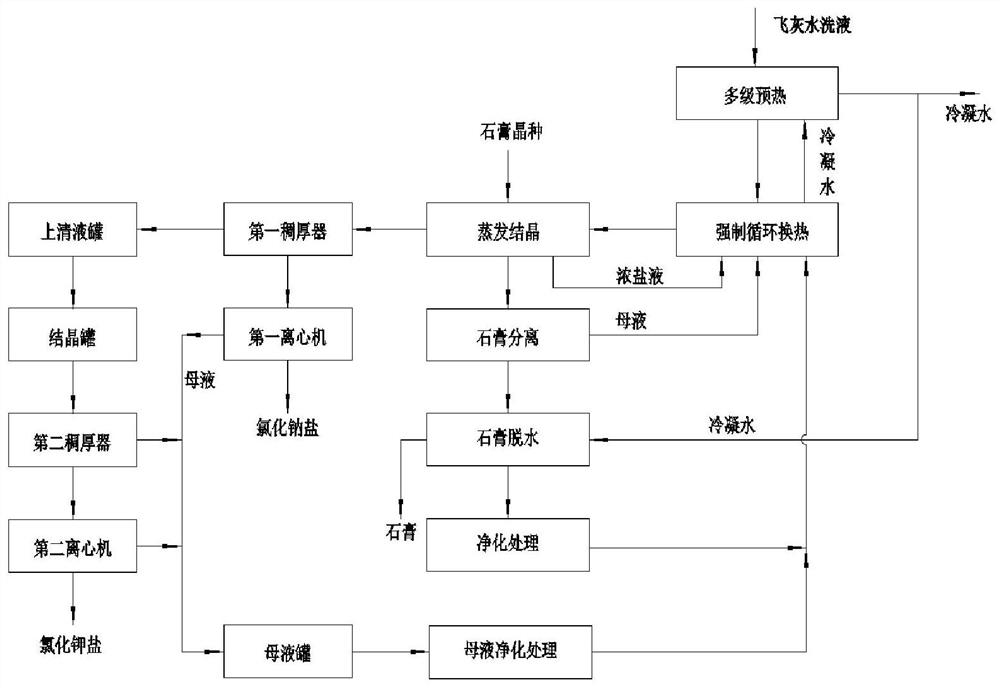

[0072] Example 2 Fly Ash Washing Crystallization Separation System Based on Seed Method and Separation and Purification of Sodium and Potassium Salts

[0073] refer to figure 2 and Figure 4 , proceed as follows:

[0074] a. The purified fly ash washing liquid enters the multi-stage preheater 1 for preheating.

[0075] b. The preheated feed liquid is subjected to evaporation and concentration treatment in the forced circulation heat exchanger 2 to obtain concentrated feed liquid.

[0076] c. After the concentrated feed liquid is crystallized and layered in the evaporative crystallizer 4, crystal slurry liquid with a salt content of 30wt%-60wt%, concentrated salt solution and salt slurry with a salt content of 30wt%-60wt% are obtained.

[0077] d. Add 15-30g / L gypsum seeds to the evaporative crystallizer,

[0078] e. The crystal slurry liquid enters the gypsum separator 5 for separation and treatment, and obtains crystalline gypsum and gypsum mother liquor with a water con...

Embodiment 3

[0081] Example 3 Fly Ash Washing Crystallization Separation System Based on Seed Method and Separation and Purification of Sodium and Potassium Salts

[0082] refer to Figure 5 , the difference from Example 2 is that the concentrated salt solution obtained by the evaporative crystallizer 4 passes through the second forced circulation heat exchanger 18 successively, and the first forced circulation heat exchanger 2 returns to the evaporative crystallization after two times of evaporation and concentration In the device 4, multiple forced circulation evaporation and concentration treatments are carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com