Method for oxidizing pollutants in water through electricity/ozone/permanganate coupling

A permanganate and water oxidation technology, applied in the field of water treatment, can solve the problems of low production efficiency of active species, large dosage of oxidant, secondary pollution, etc., to increase fluid turbulence and reduce the amount of metal used , the effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

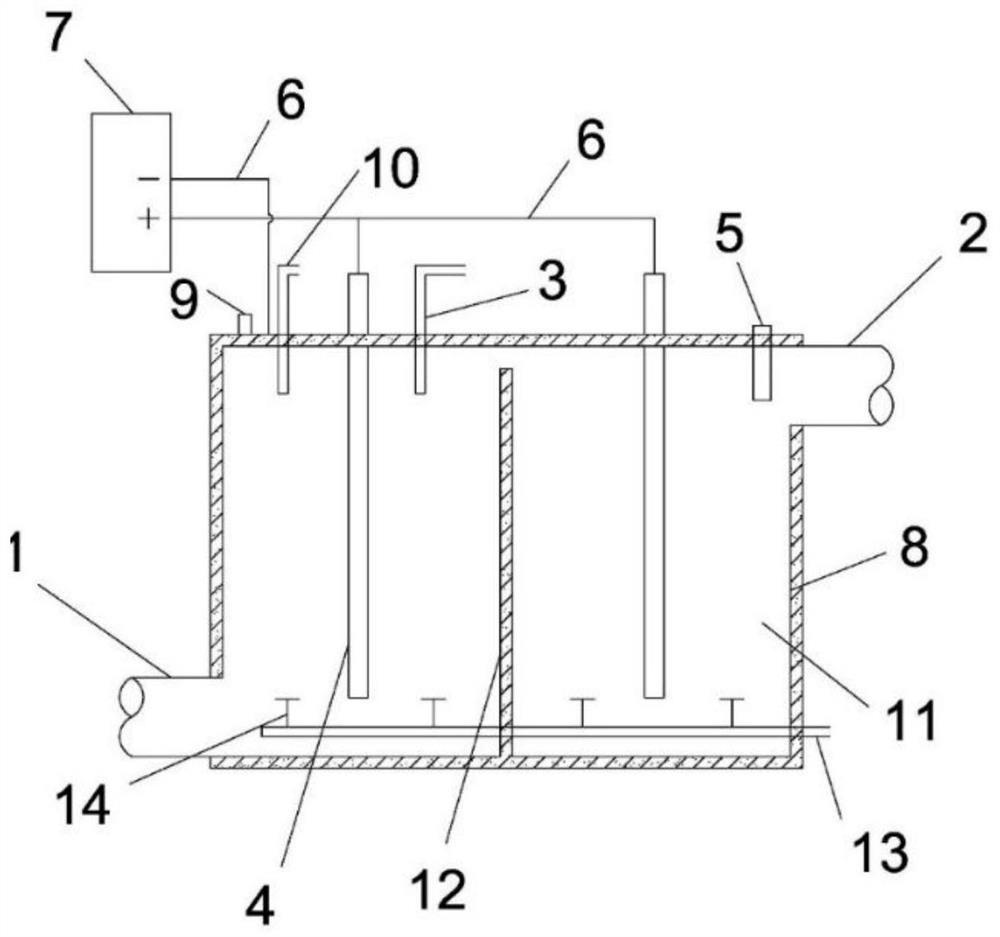

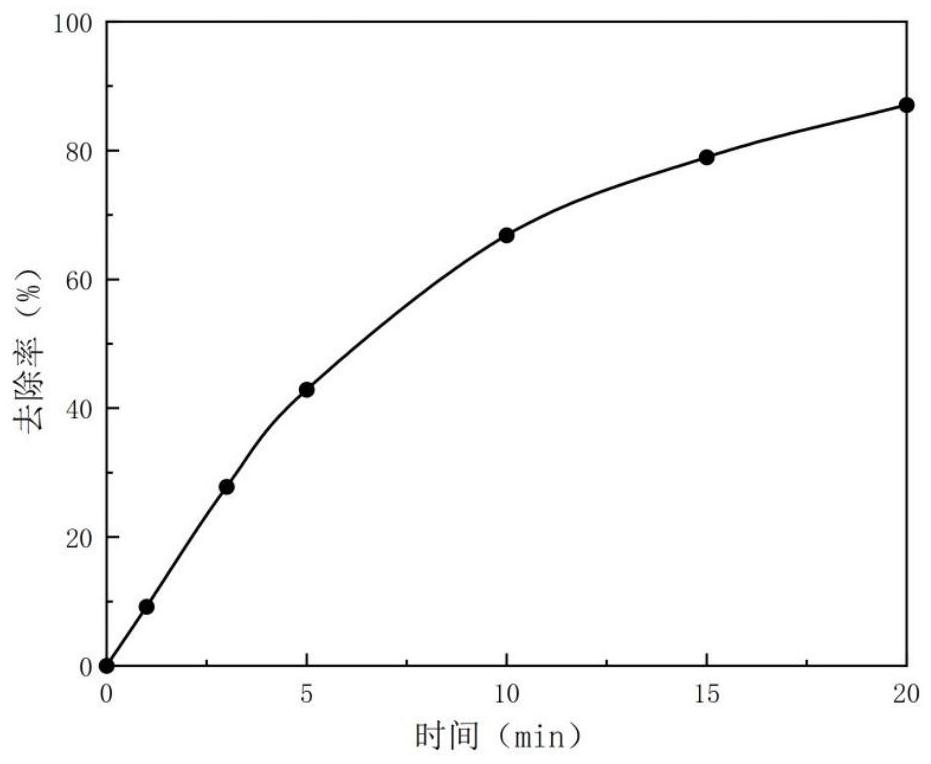

[0041] Adopt the electrode reactor of above-mentioned oxidation device of the present invention to process the sewage containing 60 μ mol / L diclofenac, specifically comprise the following steps:

[0042] The sewage to be treated is injected into the reaction chamber of the cathode / anode electrode system (the anode is a platinum-plated titanium electrode, and the cathode is a platinum-plated titanium electrode). Add sodium sulfate to make the concentration 0.05 mol / L, and add potassium permanganate aqueous solution to make it The concentration of potassium permanganate was 100 μmol / L, ozone was added at an aeration rate of 60 ml / min to make the concentration 1 mg / L, and the DC power supply was started to keep the concentration of permanganate at 100 μmol / L and The applied current intensity was 20 mA, and after 20 min of treatment, the treated sewage was discharged from the water outlet.

[0043] Record the concentration change of diclofenac in the sewage to be treated in this e...

Embodiment 2

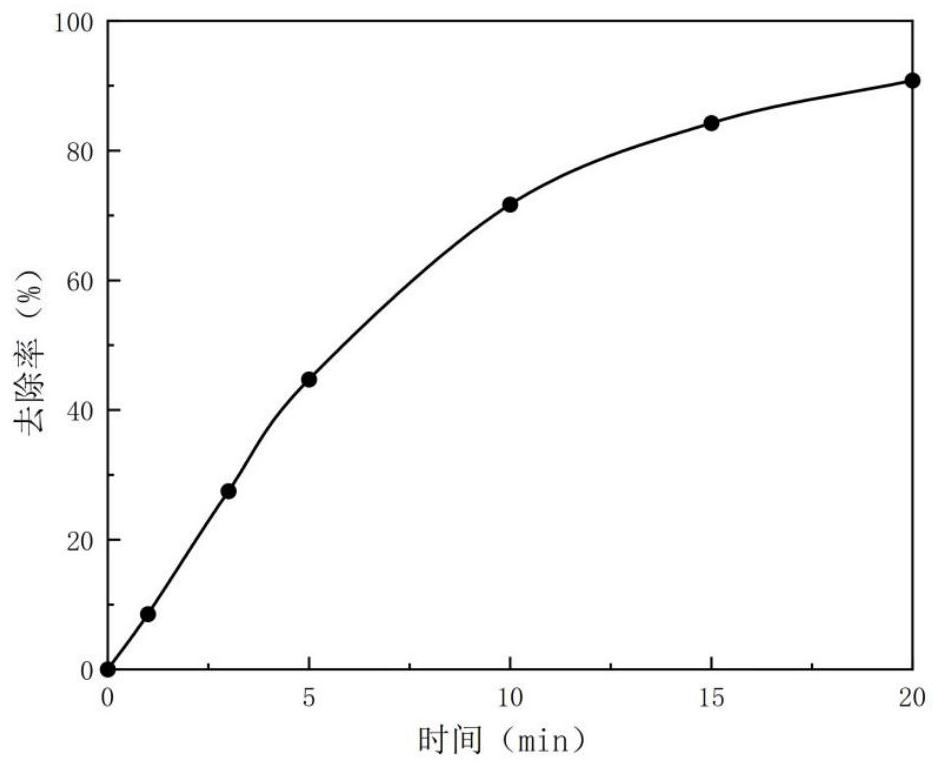

[0045] Adopt the electrode reactor of above-mentioned oxidation device of the present invention to process the sewage containing 60 μ mol / L diclofenac, specifically comprise the following steps:

[0046] The sewage to be treated is injected into the reaction chamber of the cathode / anode electrode system (the anode is a platinum-plated titanium electrode, and the cathode is a platinum-plated titanium electrode). Add sodium sulfate to make the concentration 0.05 mol / L, and add potassium permanganate aqueous solution to make it The concentration of potassium permanganate was 150 μmol / L, ozone was added at an aeration rate of 60 ml / min to make the concentration 1 mg / L, and the DC power was turned on to keep the concentration of permanganate at 150 μmol / L and The applied current intensity was 20 mA, and after 20 min of treatment, the treated sewage was discharged from the water outlet.

[0047] Record the concentration change of diclofenac in the sewage to be treated in this embodi...

Embodiment 3

[0049] Adopt the electrode reactor of above-mentioned oxidation device of the present invention to process the sewage containing 60 μ mol / L diclofenac, specifically comprise the following steps:

[0050] The sewage to be treated is injected into the reaction chamber of the cathode / anode electrode system (the anode is a platinum-plated titanium electrode, and the cathode is a platinum-plated titanium electrode). Add sodium sulfate to make the concentration 0.05 mol / L, and add potassium permanganate aqueous solution to make it The concentration of potassium permanganate was 100 μmol / L, and ozone was added at an aeration rate of 60 ml / min to make the concentration 2.5 mg / L, and the DC power supply was started to keep the concentration of permanganate at 100 μmol / L and The applied current intensity was 20 mA, and after 20 min of treatment, the treated sewage was discharged from the water outlet.

[0051] Record the concentration change of diclofenac in the sewage to be treated in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com