Low-heavy-metal biogas residue composite organic silicon fertilizer with slow release function and preparation method of low-heavy-metal biogas residue composite organic silicon fertilizer

A technology with low heavy metals and organic silicon, applied in organic fertilizers, inorganic fertilizers, magnesium fertilizers, etc., can solve the problems of single nutrient, can not provide N, P and organic matter, etc., achieve high adsorption capacity, rich surface charge, low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation method of the low-heavy metal biogas residue compound organic silicon fertilizer with slow-release function, it comprises the steps:

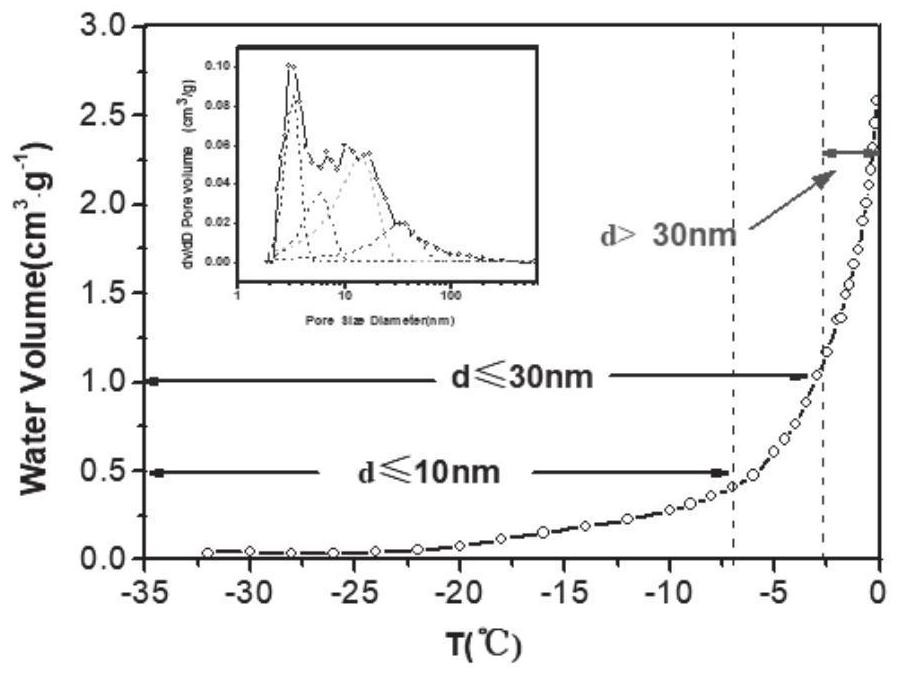

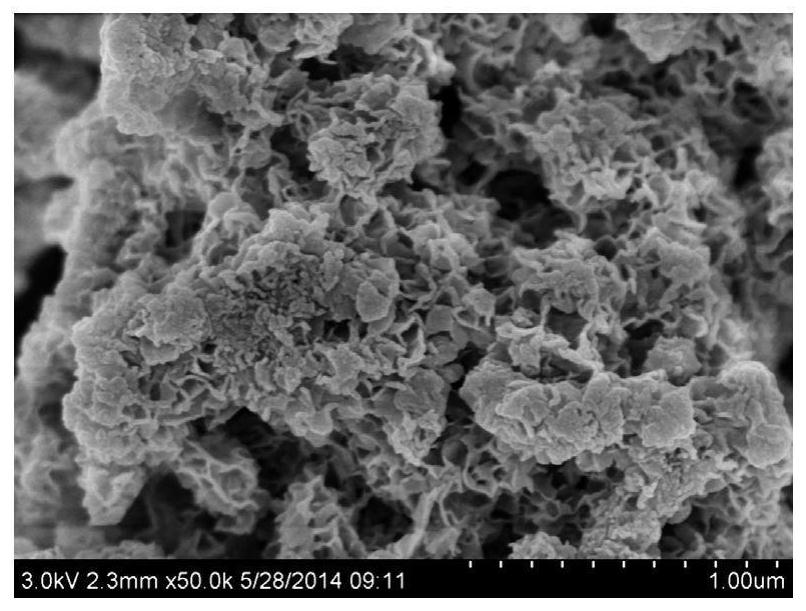

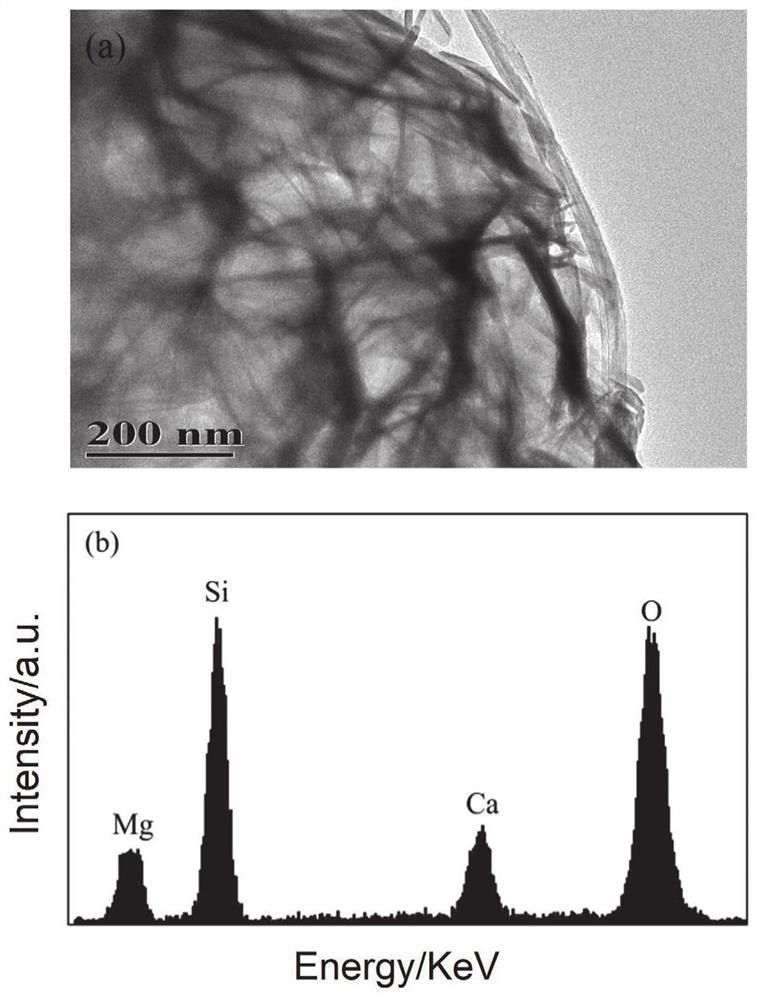

[0040] (1) Separation of the upper liquid and the remaining substrate after the pretreatment of the biogas residue: take 500 kg of calcium-magnesium-silicon functional material with hierarchical pore distribution and mix it with 4 tons of biogas residue, stir for 50 minutes and let it stand for 30 minutes, then separate the upper liquid , the remaining substrate is a mixture of the remaining calcium-magnesium-silicon functional materials and biogas residue; wherein, the biogas residue is obtained by co-digesting multiple substrates such as livestock and poultry manure and straw.

[0041] (2) The remaining substrate is dehydrated, dried and ground to prepare the substrate powder; in the present embodiment, after the remaining substrate is put into a screw extruder to remove excess moisture, it is dried in a dr...

Embodiment 2

[0053] Embodiment 2: the preparation method of the low-heavy metal biogas residue composite organic silicon fertilizer with slow-release function, it comprises the steps:

[0054] (1) Separation of the upper liquid and the remaining substrate after the pretreatment of the biogas residue: take 100 kg of calcium-magnesium-silicon functional material with hierarchical pore distribution and mix it with 1 ton of biogas residue, stir for 15 minutes and let it stand for 15 minutes, then separate the upper liquid , the remaining substrate is a mixture of the remaining calcium-magnesium-silicon functional materials and biogas residue; wherein, the biogas residue is obtained by co-digesting multiple substrates such as livestock and poultry manure and straw.

[0055] (2) The remaining substrate is dehydrated, dried and ground to prepare the substrate powder; in the present embodiment, after the remaining substrate is put into a screw extruder to remove excess moisture, it is dried in a dr...

Embodiment 3

[0066] Embodiment 3: the preparation method of the low-heavy metal biogas residue composite organic silicon fertilizer with slow-release function, it comprises the steps:

[0067] (1) Separation of the upper liquid and the remaining substrate after the pretreatment of the biogas residue: take 800 kg of calcium-magnesium-silicon functional material with hierarchical pore distribution and mix it with 8 tons of biogas residue, stir for 100 minutes and let stand for 50 minutes, then separate the upper liquid , the remaining substrate is a mixture of the remaining calcium-magnesium-silicon functional materials and biogas residue; wherein, the biogas residue is obtained by co-digesting various substrates such as livestock manure and straw.

[0068] (2) The remaining substrate is dehydrated, dried and ground to prepare the substrate powder; in the present embodiment, after the remaining substrate is put into a screw extruder to remove excess moisture, it is dried in a drier for 12 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com