Silicon carbide crystal and preparation method thereof

A technology of silicon carbide and crystal, which is applied in the field of silicon carbide crystal and its preparation, can solve the problems of crystal growth rate limitation, incapability of large-scale use, increasing crystal graphitization, etc., to reduce crystal defects, increase sublimation rate and Utilization rate, effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

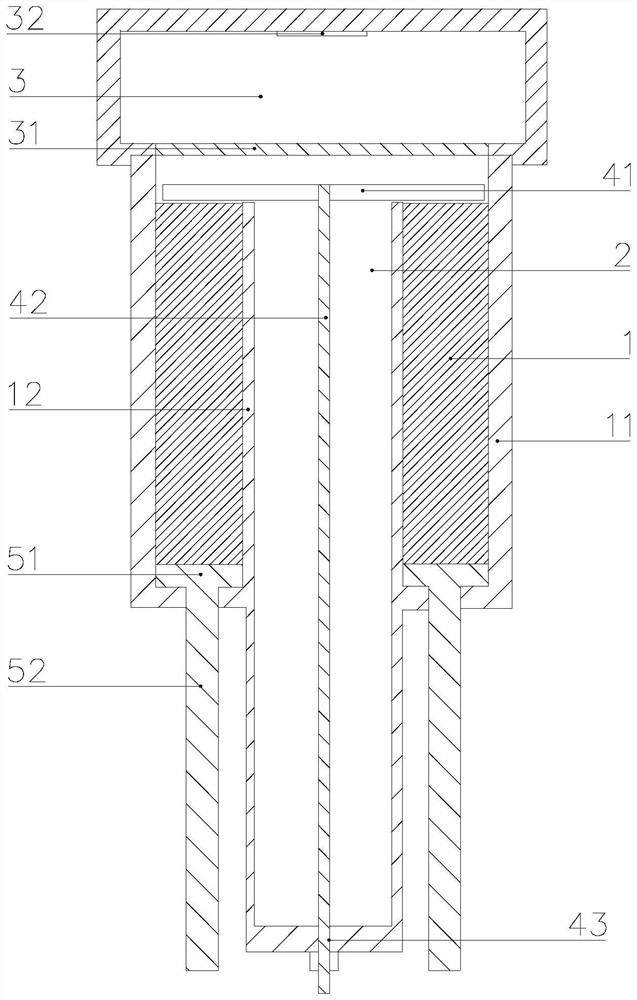

[0093] refer to Figure 1-3 , the embodiment of the application discloses a kind of reactor assembly that is used for growing crystal, and this reactor assembly comprises reaction chamber, crystal growth chamber 3 and material removing mechanism; Reaction chamber comprises raw material chamber 1 and waste material chamber 2, and crystal growth chamber 3 communicates with the raw material chamber 1 through the gas phase transmission channel, and the raw material gas generated by the sublimation of the raw material in the raw material chamber 1 is transported to the crystal growth chamber 3 through the gas phase transmission channel, and the material removal mechanism removes the gas generated during the crystal growth process in the raw material chamber 1 The waste is transferred to waste chamber 2.

[0094] Specifically, the raw material cavity 1 and the waste material cavity 2 are separate chambers, and the separate raw material cavity 1 and the waste material cavity 2 can be...

Embodiment 2

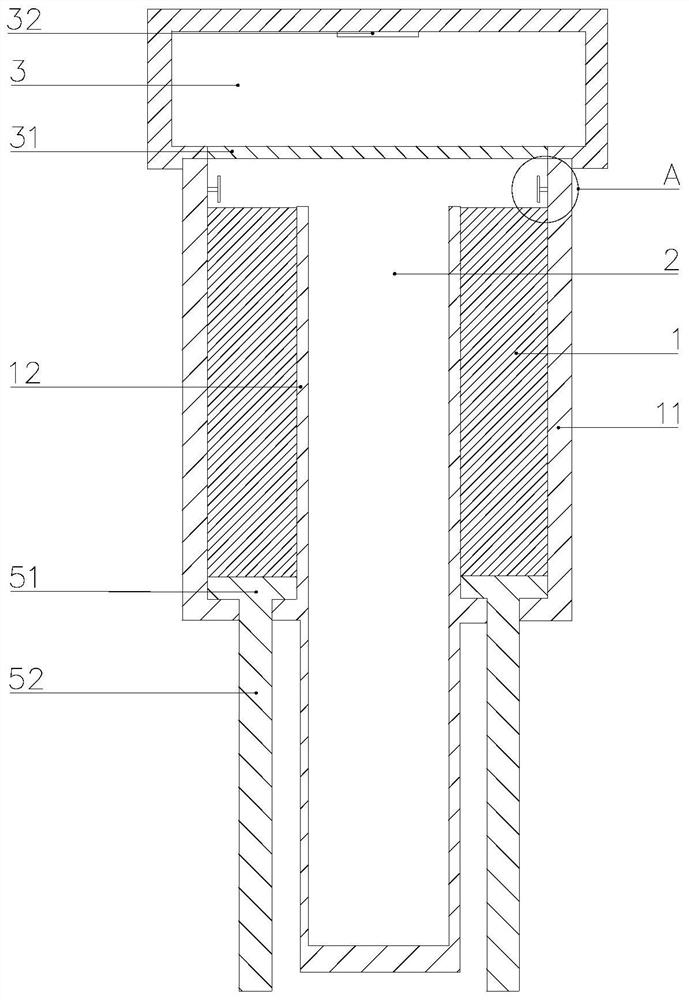

[0124] refer to Figure 4 The difference between this embodiment and Embodiment 1 is that the waste chamber 2 is sleeved on the periphery of the raw material chamber 1, and the waste chamber 2 is formed between the reaction chamber outer cylinder 11 and the reaction chamber inner cylinder 12, and the reaction chamber inner cylinder 12 forms the raw material chamber 1. In this setting mode, the top of the raw material chamber 1 is a high-temperature area, and the raw material is sublimated to grow crystals. The material removal mechanism removes the waste in the raw material chamber 1 in time, so that the waste falls into the bottom of the waste chamber 2. At this time, the waste is far away from the high-temperature area and cannot Continue to be sublimated by heat, avoid crystal defects caused by waste materials, and further improve the growth quality of crystals.

[0125] As an embodiment, the material receiving platform 51 pushes the raw material in the raw material chambe...

Embodiment 3

[0128] In an embodiment not shown, the raw material chamber 1 is formed between the reaction chamber outer cylinder 11 and the reaction chamber inner cylinder 12, and the waste material chamber 2 is arranged at the bottom, the top of the raw material chamber 1 or the outside of the reaction chamber outer cylinder 11, inside the reaction chamber The porosity of the surface of the cylinder 12 is higher than that of the surface of the reaction chamber outer cylinder 11. The seed crystal is arranged in the reaction chamber inner cylinder 12 in the form of a column. The extension direction of the seed crystal and the central axis of the reaction chamber inner cylinder 12 is roughly the same. A crystal growth chamber 3 is formed between the crystal and the inner side wall of the reaction chamber inner cylinder 12, and the heating device is arranged on the outside of the reaction chamber outer cylinder 11, so that the raw material gas in the raw material chamber 1 passes through the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com