Experimental system for ultra-low emission research of supercritical CO2 coal-fired boiler

A technology for coal-fired boilers and experimental systems, which is applied in the directions of emission prevention, combustion using multiple fuels, combustion using lump fuels and liquid fuels, etc. Low efficiency and other problems, to achieve the effect of reducing NOX and pollutant content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

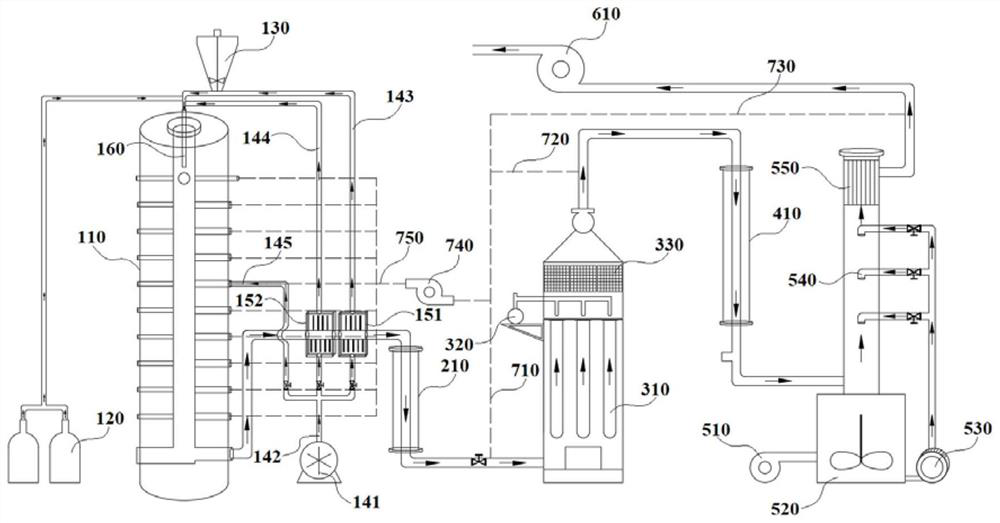

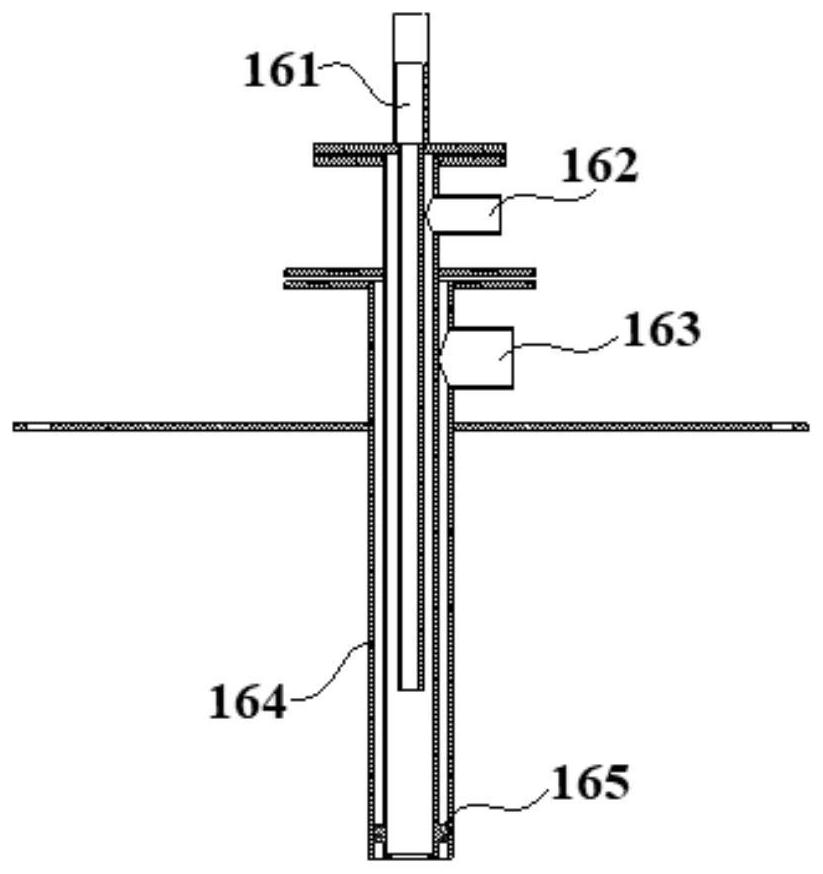

[0044] combine figure 1 with figure 2 , a supercritical CO of this embodiment 2 The experimental system for ultra-low emission research of coal-fired boilers includes a combustion unit, a dust removal and denitrification unit, a desulfurization unit, and a flue gas circulation unit. The combustion unit includes a furnace body 110, a powder feeder 130 and a swirl burner 160. The swirl burner 160 is arranged inside the upper end of the furnace body 110, the powder feeder 130 is connected with the swirl burner 160 through a pipeline, and the powder feeder 130 is equipped with pulverized coal, and the pulverized coal is transported along the pipeline To the swirl burner 160, so as to enter the inside of the furnace body 110 to facilitate subsequent combustion. In addition, a liquefaction tank 120 is provided on one side of the furnace body 110, and liquefied petroleum gas is housed in the liquefaction tank 120. The liquefaction tank 120 passes through the pipeline It communicat...

Embodiment 2

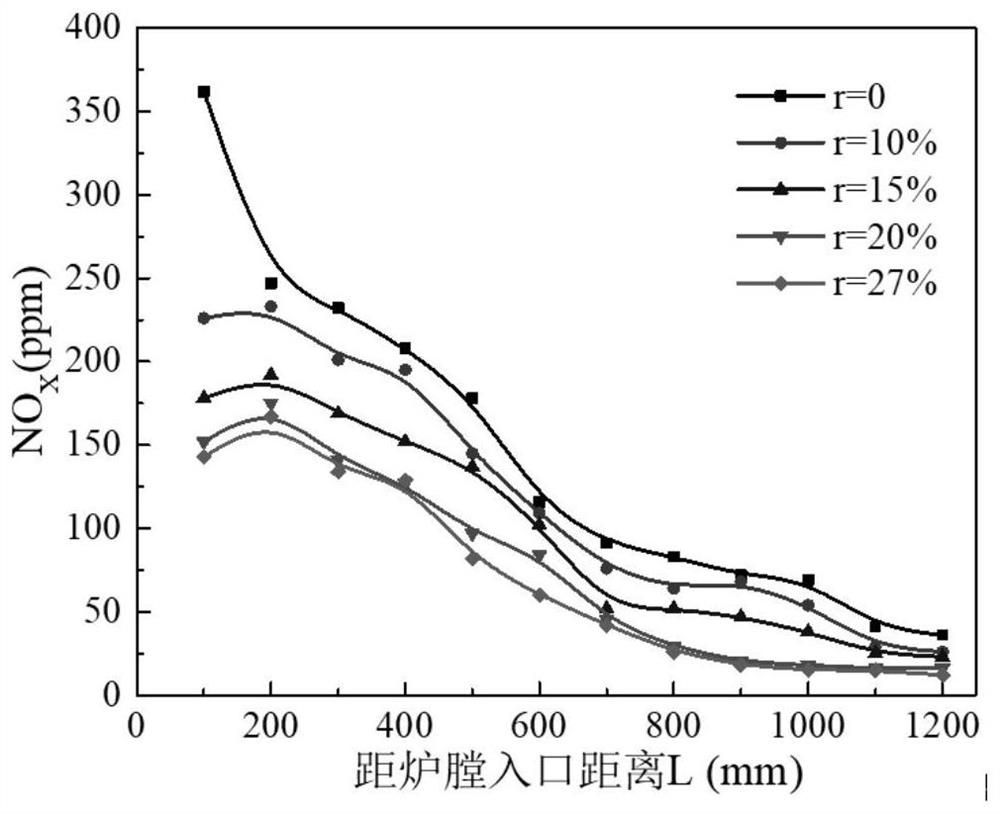

[0063] A kind of supercritical CO of the present embodiment 2 The experimental system for research on ultra-low emissions of coal-fired boilers is basically the same as in Example 1. Furthermore, in this example, additives are injected into the pulverized coal combustion area in the furnace body 110. The additives include anti-slagging and anti-coking additives, deNOx One or more of the agent, sulfur-fixing agent or coal-burning catalyst; wherein, the anti-slagging and anti-coking additive is titanium isopropoxide or silicon-aluminum type additive, and the silicon-alumina type additive can be kaolin, vermiculite , SiO 2 Or one or more of fly ash. When titanium isopropoxide is added, its addition ratio accounts for 3% to 5% of the amount of coal fed into the furnace; when silicon aluminum type additives are added, the general control quality accounts for 2% to 10% of the total mass of coal powder. Si-aluminum additives or titanium isopropoxide can improve the ash melting poin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com