Kitchen waste treatment method

A technology of food waste and treatment methods, which is applied in the direction of sedimentation treatment, special treatment targets, water/sewage treatment, etc., and can solve the problems of large power consumption in high-temperature composting treatment, large investment in biogas power generation treatment projects, and high salt and oil content in products. , to achieve excellent coagulation treatment effect, improve comprehensive management ability, and strong biological adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

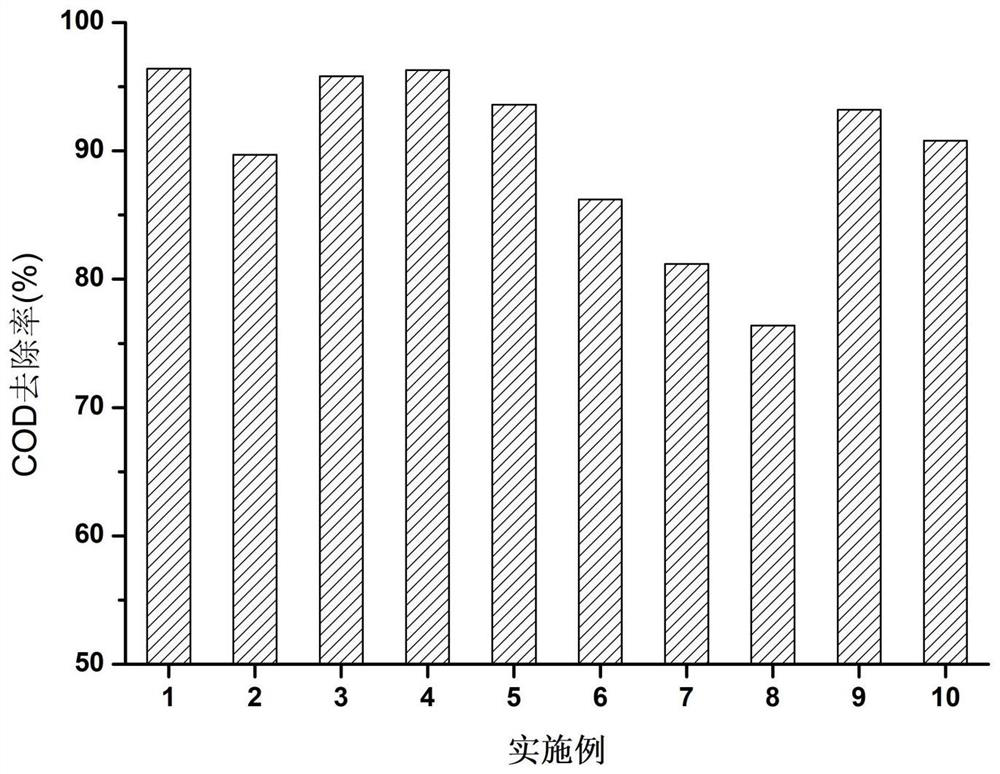

Embodiment 1

[0088] Embodiment 1: a kind of kitchen waste processing method:

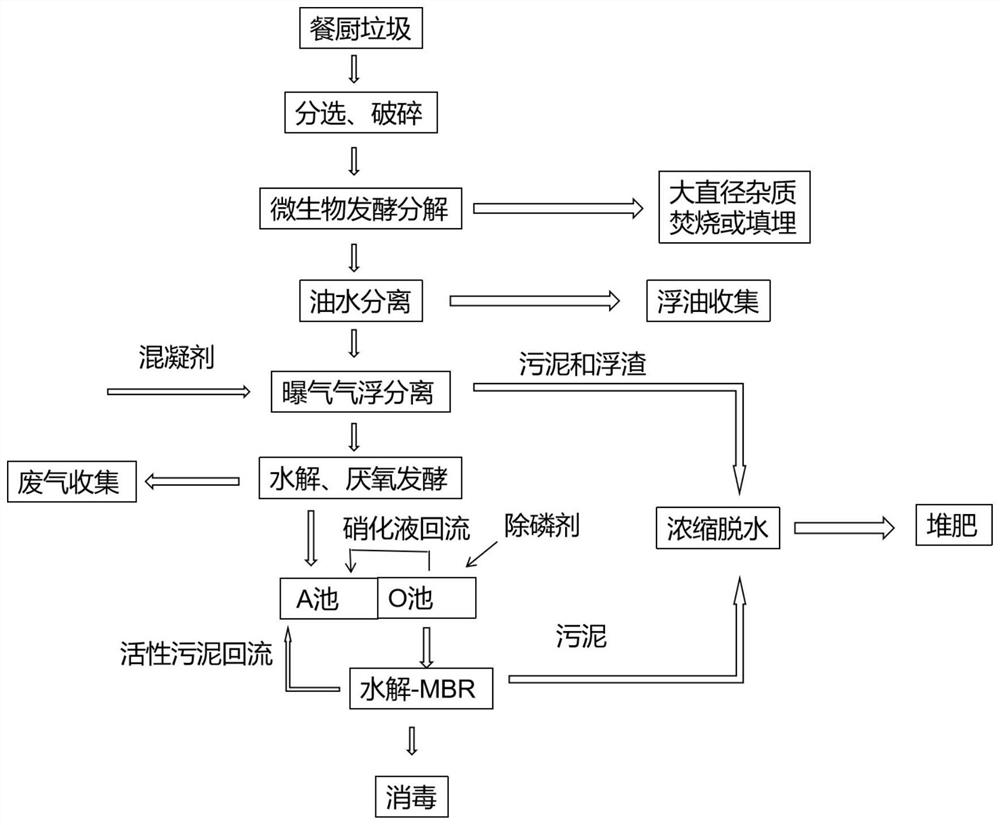

[0089] This embodiment provides a kind of food waste processing method, its flow chart is as attached figure 1 shown, including:

[0090] Step 1. Sorting and crushing: Preliminary sorting of kitchen waste, the sorted large foreign matter is transferred to incineration or landfill, and the remaining matter is crushed;

[0091] Step 2. Microbial fermentation and decomposition: add polyurethane filler and composite microbial degradation bacteria to the kitchen waste, stir and ferment, separate and transport large-diameter impurities for incineration or landfill;

[0092] Step 3. Oil-water separation: The landfill leachate produced by microbial fermentation and decomposition is transported to the oil-water separation system for separation, and the separated oil phase is recycled and reused;

[0093] Step 4. Aeration and air flotation separation: use an air flotation machine to separate the leachate separated from ...

Embodiment 2

[0107] Embodiment 2: another kind of food waste processing method:

[0108] This embodiment provides another method for treating food waste, the steps of which are basically the same as in Embodiment 1, the difference is that in this embodiment, in the aeration and air flotation separation process, the flocculant includes: a weight ratio of 1 : 15:3 polyacrylamide, activated carbon, sodium palmitate; that is, the use of activated carbon instead of arbutin modified activated carbon;

[0109] The flocculant is prepared by the following method:

[0110] Mix polyacrylamide, activated carbon, and sodium palmitate into 90g of deionized water, raise the temperature to 70°C at a rate of 3°C / min, stir at 400r / min to make it fully mixed, and naturally cool to room temperature and place it for 6h; Then heat up to 90°C at a rate of 8°C / min and stir thoroughly until the water content of the mixture is lower than 5%, and cool naturally to obtain a flocculant.

Embodiment 3

[0111] Embodiment 3: another kind of food waste processing method:

[0112] This embodiment provides another method for treating kitchen waste, the steps of which are basically the same as in Embodiment 1, the difference is that in this embodiment, in the aeration and air flotation separation process, the arbutin in the flocculant is modified The amount of activated carbon and arbutin added during the preparation of activated carbon was 10 g and 1.55 g, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com