Thin-layer MXene/hexagonal crystal phase molybdenum disulfide composite material, and preparation method and application thereof

A technology of hexagonal crystal phase and molybdenum disulfide, applied in molybdenum sulfide, nanotechnology for materials and surface science, analytical materials, etc., can solve the problems of long detection time, high detection limit, high cost, etc., and achieve high gas sensitivity Sex and response speed, simple operation, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

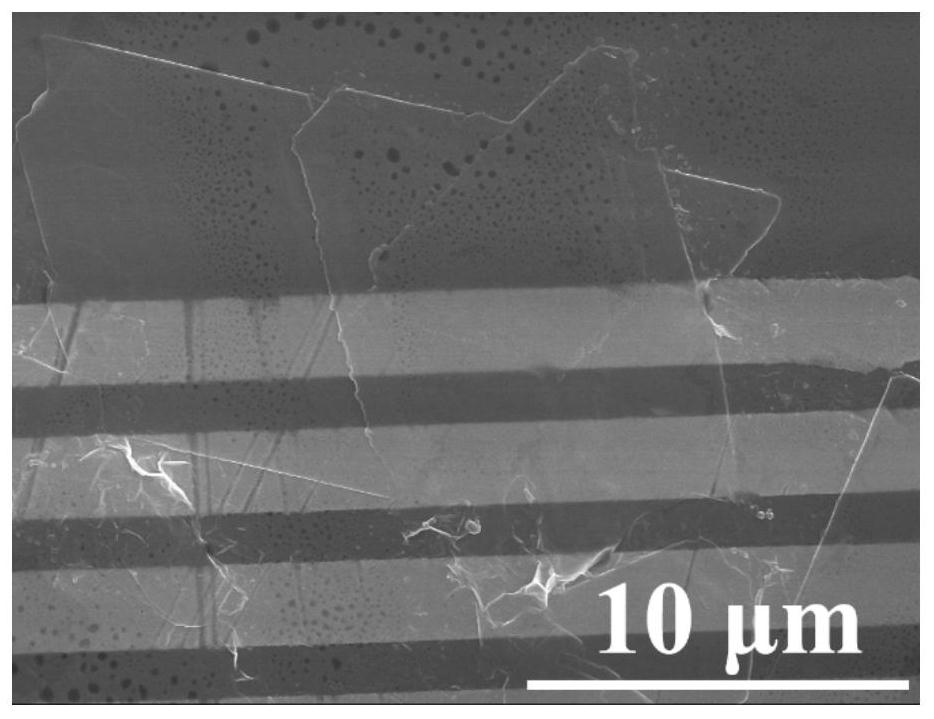

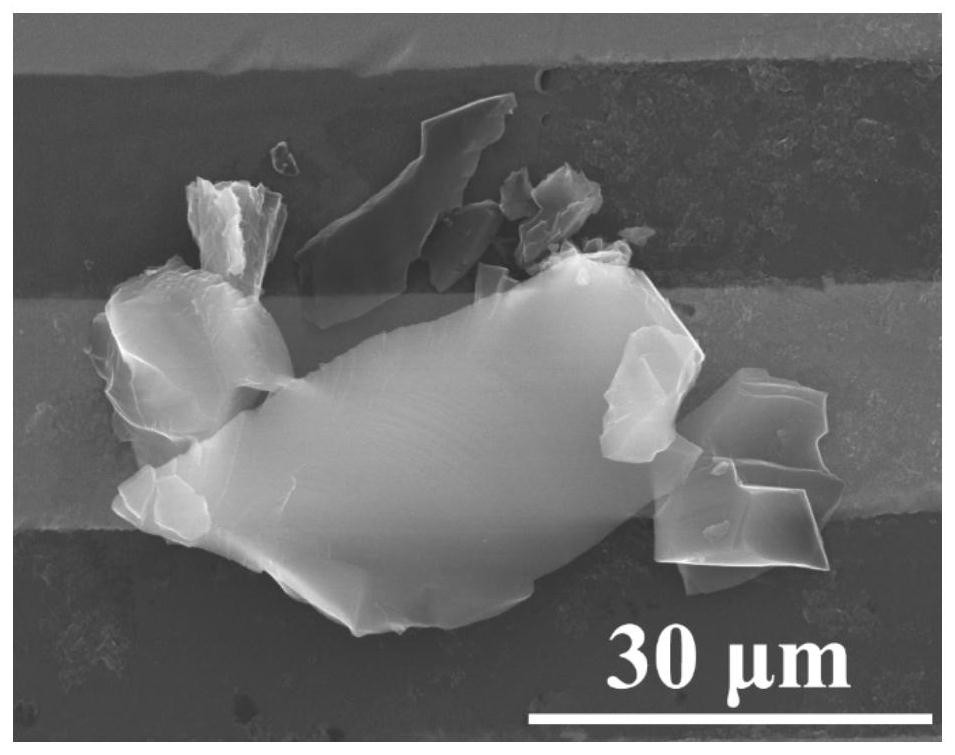

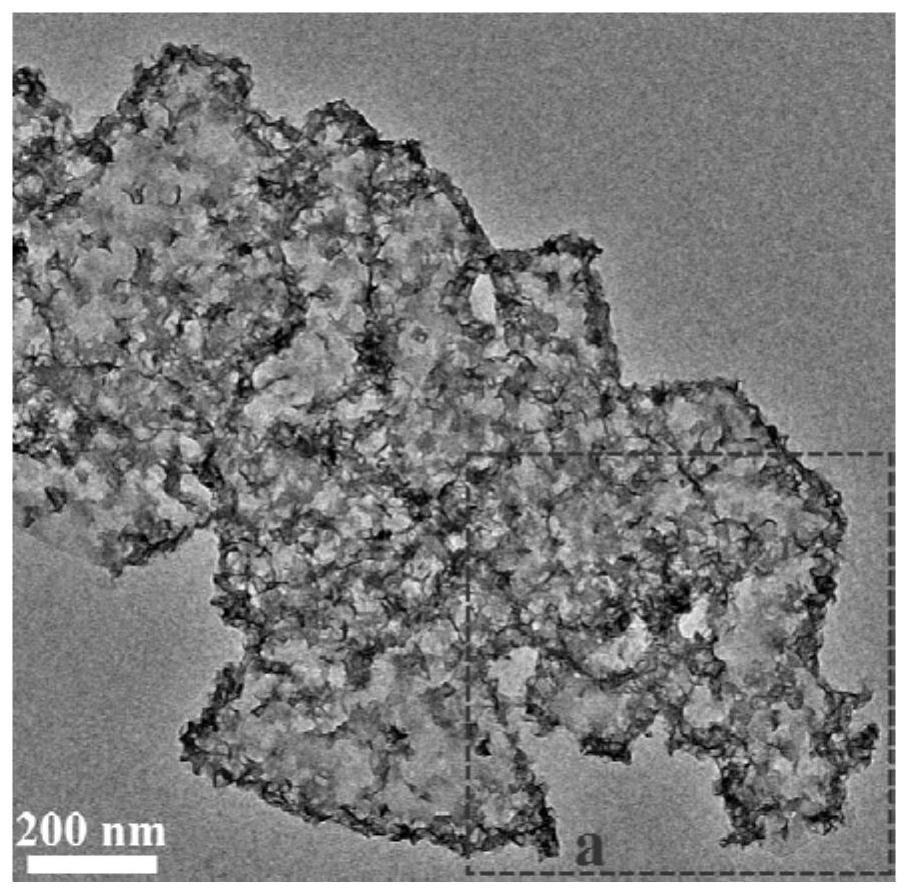

[0037] Embodiment 1: In this embodiment, a thin-layer MXene / hexagonal molybdenum disulfide composite material is prepared from two-dimensional transition metal carbides, molybdenum-containing compounds, sulfur-containing compounds, weak acids and surfactants as raw materials.

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the two-dimensional transition metal carbide is titanium carbide, calcium carbide, chromium carbide, tantalum carbide, vanadium carbide, zirconium carbide, tungsten carbide or molybdenum carbide ; The molybdenum-containing compound is ammonium molybdate, sodium molybdate or ammonium tetrathiomolybdate. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Specific embodiment three: the differences between this embodiment and specific embodiment one or two are: the sulfur-containing compound is thiourea or thioacetamide; the weak acid is oxalic acid, citric acid or phosphoric acid; the The preferred surfactant is sodium benzenesulfonate, ethylene oxide or pyrrolidone. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com