Preparation method and application of NiCu/BDD composite electrode used for directional catalytic oxidation of ammonia nitrogen in wastewater

A composite electrode and catalytic oxidation technology, which is applied in chemical instruments and methods, water/sewage treatment equipment, energy wastewater treatment, etc., can solve the problems of low selectivity of product N2, unknown selectivity, and reduced electrode oxidation performance. The effect of high product N2 selectivity, high electron transfer rate, and accelerated ammonia oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

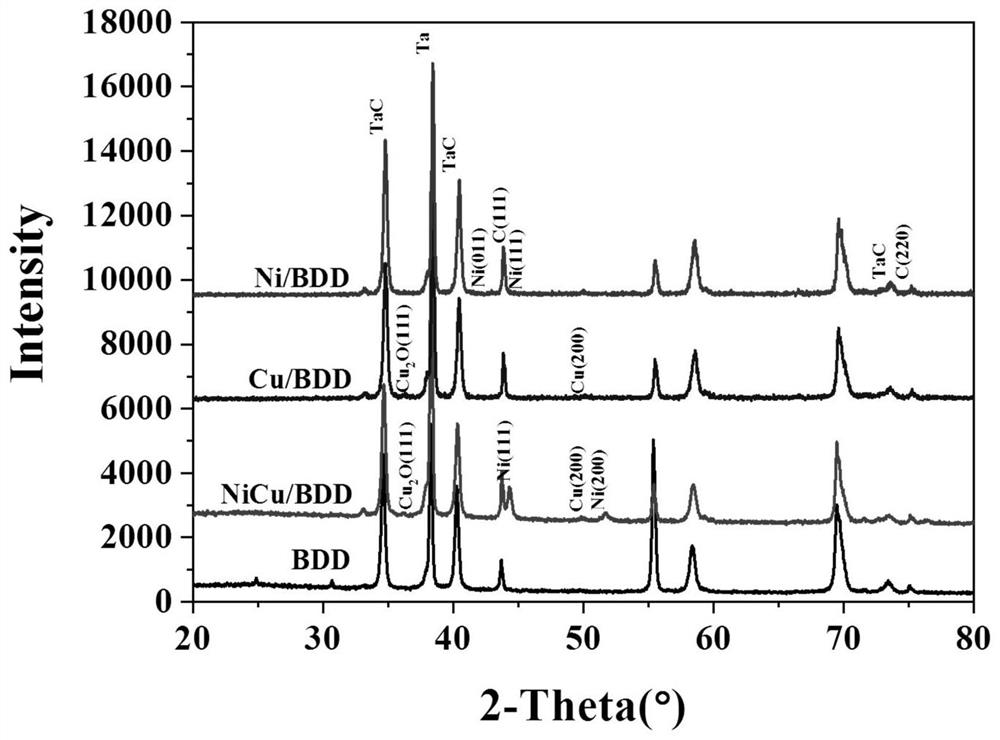

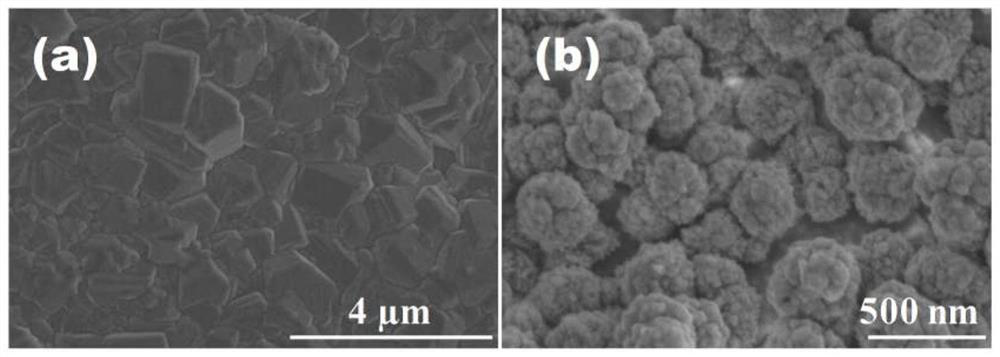

[0044] 1. Synthesis of NiCu / BDD electrode: After the BDD electrode was prepared by hot wire vapor deposition (HFCVD), the prepared BDD electrode was cleaned with 50ml of 5M HCl, acetone, ethanol, and ultrapure water in sequence for 20 minutes, and placed in an oven. Dry at 60°C. Take 6.57g NiSO 4 ·6H 2 O, 0.625g CuSO 4 ·5H 2 O. Dissolve 7.21g of sodium dodecyl sulfate (SDS) in 50ml of water and stir for 2h to fully mix. The pretreated BDD, Pt sheet, and Ag / AgCl were used as the working electrode, counter electrode, and reference electrode, respectively, and were deposited at a voltage of -1.3V for 20s. Wash the deposited electrode with ultrapure water, and ventilate in a ventilated place for 24 hours.

[0045] The BDD electrode preparation process in this embodiment is:

[0046] Step 1: Bottom pretreatment. The pretreatment of tantalum sheet includes two parts: mechanical grinding and seeding. Firstly, the metallographic sandpaper of mesh number P600 and P1000 was used...

Embodiment 2

[0088] 1. Synthesis of NiCu / BDD electrode: After the BDD electrode was prepared by hot wire vapor deposition (HFCVD), the prepared BDD electrode was cleaned with 50ml of 5M HCl, acetone, ethanol, and ultrapure water in sequence for 20 minutes, and placed in an oven. Dry at 60°C. Take 6.57g NiSO 4 ·6H 2 O, 0.625g CuSO 4 ·5H 2 O. Dissolve 7.21g of sodium dodecyl sulfate (SDS) in 50ml of water and stir for 2h to fully mix. The pretreated BDD, Pt sheet, and Ag / AgCl were used as the working electrode, counter electrode, and reference electrode, respectively, and were deposited at a voltage of -1.3V for 20s. Wash the deposited electrode with ultrapure water, and ventilate in a ventilated place for 24 hours.

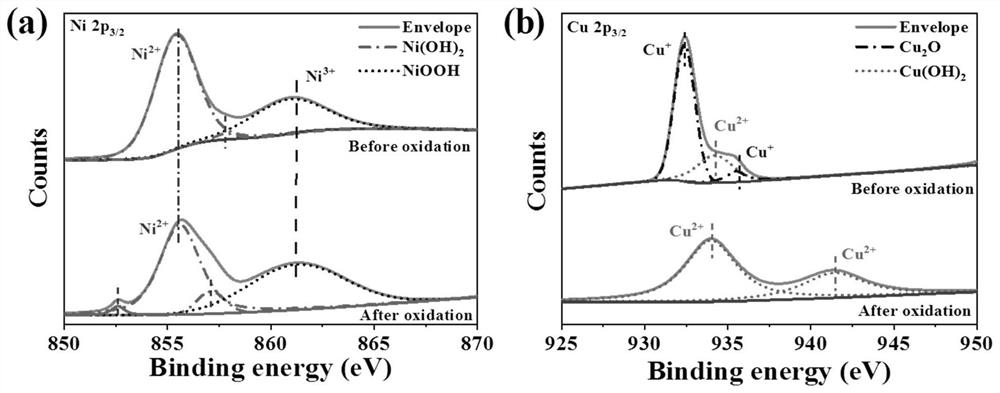

[0089] 2. Activation treatment of electrodes

[0090] (1) Use a three-electrode system, the working electrode is a Ni / BDD electrode, the counter electrode is a Pt sheet, the reference electrode is a saturated silver / silver chloride electrode, and the electrolyte is 0.5M N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com