A kind of preparation method of controllable molecular weight polyacrylate pentabromobenzyl ester

A technology of poly(pentabromobenzyl acrylate and molecular weight) is applied in the field of preparation of controllable molecular weight poly(pentabromobenzyl acrylate), which can solve the problems of uneven molecular weight distribution, imperfect purification process, low heat resistance and the like, and achieves the The effect of stable product quality, low cost and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

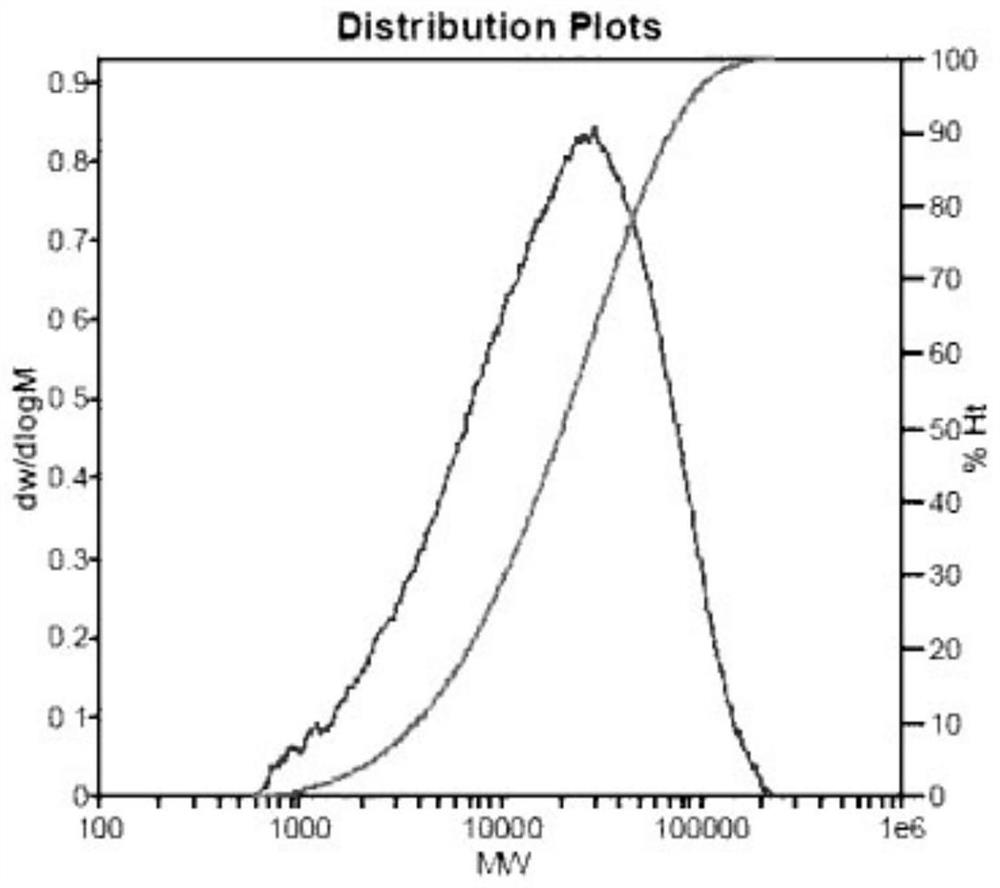

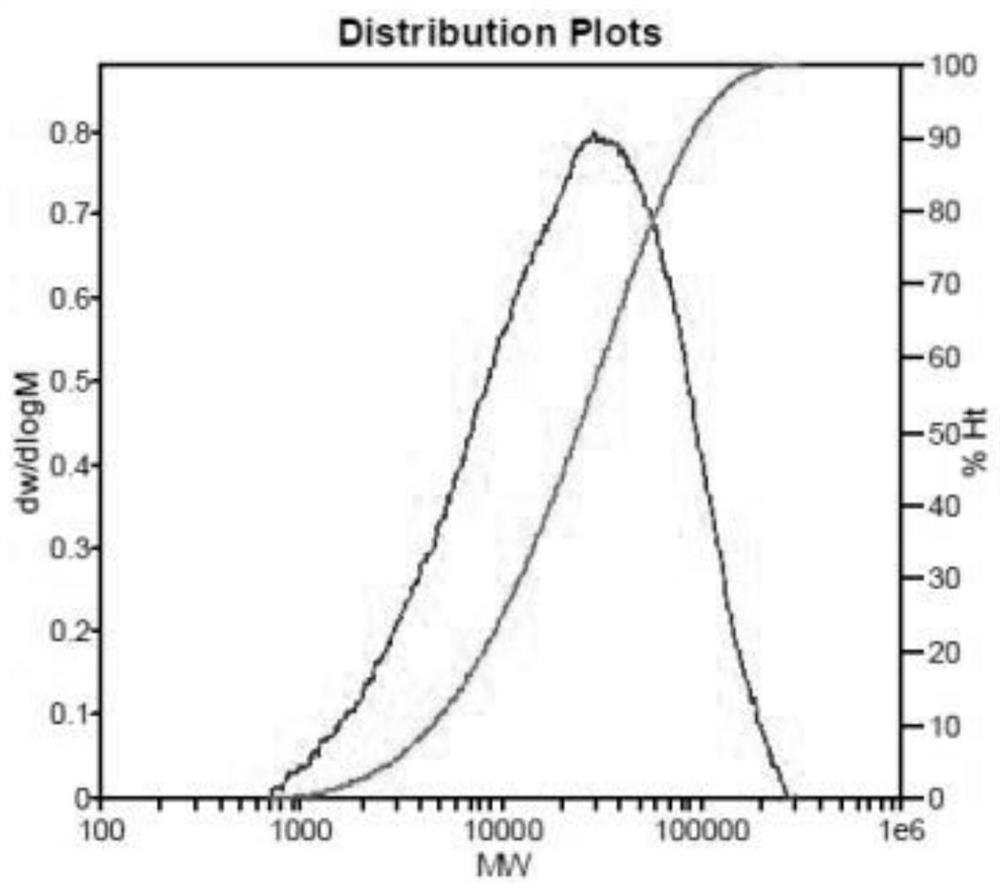

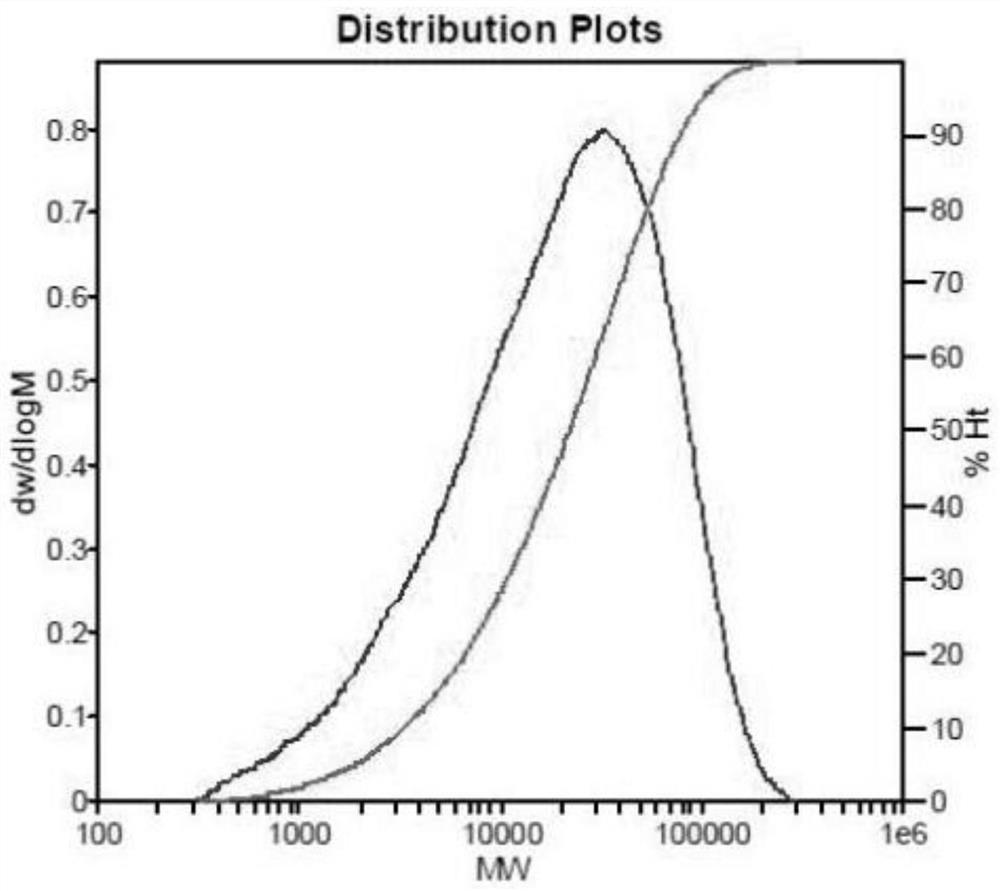

Image

Examples

Embodiment 1

[0029] (1) electrophilic substitution reaction: add 640g anhydrous bromine, 0.5g catalyst aluminum trichloride, 250g dichloroethane in the reaction kettle, be cooled to 10 DEG C, slowly drop 100g benzyl chloride into the reaction kettle, drip The temperature in the reaction kettle was controlled at 10°C during the addition process, the tail gas was absorbed with water, and kept for 1 hour after the dropwise addition was completed, and an electrophilic substitution reaction occurred to obtain pentabromobenzyl chloride with a yield of 98.2% and a purity of over 99%.

[0030] (2) Nucleophilic substitution reaction: 75g acrylic acid and 550g 20% sodium carbonate solution are reacted at room temperature to obtain sodium acrylate solution, and the pH value is adjusted to 7-9; pentabromobenzyl chloride is prepared in step (1). The solution was heated up, the excess bromine and residual hydrobromic acid were evaporated, then the temperature was lowered to below 50 °C, 1 g of tetrabut...

Embodiment 2

[0034] (1) electrophilic substitution reaction: add 640g anhydrous bromine, 0.5g catalyst aluminum trichloride, 250g dichloroethane in the reaction kettle, be cooled to 10 DEG C, slowly drop 100g benzyl chloride into the reaction kettle, drip The temperature in the reaction kettle was controlled at 20°C during the addition process, the tail gas was absorbed by water, and the temperature was kept for 1.5h after the dropwise addition was completed, and an electrophilic substitution reaction occurred to obtain pentabromobenzyl chloride with a yield of 98.79%.

[0035] (2) Nucleophilic substitution reaction: 75g of acrylic acid and 565g of 20% sodium carbonate solution were reacted at room temperature to obtain sodium acrylate solution, and the pH value was adjusted to 7-9; pentabromobenzyl chloride was prepared in step (1). The solution was heated up, the excess bromine and residual hydrobromic acid were evaporated, then the temperature was lowered to below 50 °C, 1 g of tetrabuty...

Embodiment 3

[0039] (1) electrophilic substitution reaction: add 700g anhydrous bromine, 5g catalyst aluminum trichloride, 550g dichloroethane in the reactor, be cooled to 10 ℃, slowly drop 100g benzyl chloride in the reactor, dropwise The temperature in the reaction kettle was controlled at 30° C., the tail gas was absorbed with water, and after the dropwise addition was completed, the temperature was kept for 2 hours, and an electrophilic substitution reaction occurred to obtain pentabromobenzyl chloride with a yield of 98.12%.

[0040](2) Nucleophilic substitution reaction: 75g acrylic acid and 580g 20% sodium carbonate solution are reacted at room temperature to obtain sodium acrylate solution, and the pH value is adjusted to 7-9; pentabromobenzyl chloride is prepared in step (1). The solution was heated up, the excess bromine and residual hydrobromic acid were evaporated, and then the temperature was lowered to below 50 °C, 1 g of tetrabutylammonium bromide was added to the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com