LDH-based composite material based on nickel-containing sludge and preparation method of LDH-based composite material

A composite material and sludge technology, which is applied to nickel compounds, chemical instruments and methods, zinc compounds, etc., can solve the problems of difficult treatment of heavy metal sludge, and achieve the effects of simple and economical preparation method, no secondary pollution, and stable properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

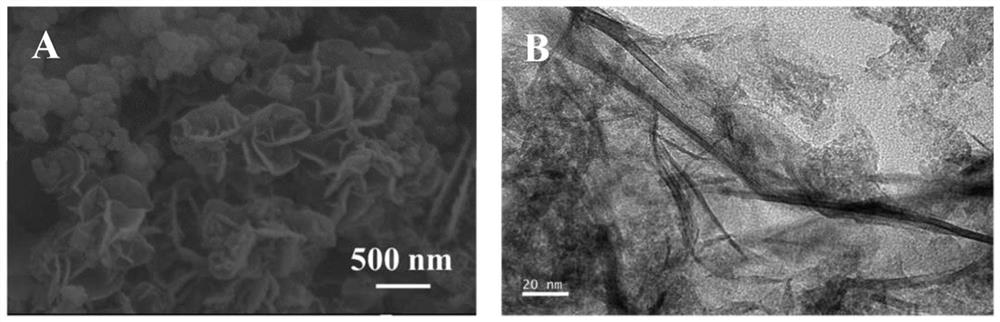

Image

Examples

Embodiment 1

[0023] A preparation method of an LDH-based composite material containing nickel sludge, comprising the steps of:

[0024] a) Dry sludge containing 13.78 wt% nickel at 120°C, grind and sieve to obtain powder with a particle size of less than 100 μm, and calcinate at 400°C for 4 hours to obtain pretreated sludge;

[0025] b) Add 0.178 g of magnesium nitrate, 4.251 g of pretreated sludge and 1.12 g of hexamethylenetetramine into 50 mL of deionized water in sequence, stir well, then add 0.204 g of alumina microspheres, mix well, and transfer to the reaction Hydrothermal treatment was carried out in the kettle, and static reaction was carried out at 180°C for 24 h. After the reaction, cool to room temperature, filter, wash with water and ethanol three times respectively, and dry at 70°C for 12 h to obtain the LDH-based composite material containing nickel sludge.

[0026] The prepared LDH-based composite material containing nickel sludge has a specific surface area of 216.96 m ...

Embodiment 2

[0029] A preparation method of an LDH-based composite material containing nickel sludge, comprising the steps of:

[0030] a) Dry sludge containing 15.63 wt% nickel at 150°C, grind and sieve to obtain a powder with a particle size of less than 100 μm, and calcinate at 500°C for 4 hours to obtain pretreated sludge;

[0031] b) Add 0.151 g of zinc nitrate, 4.506 g of pretreated sludge and 1.12 g of hexamethylenetetramine into 50 mL of deionized water in sequence, stir well, then add 0.204 g of alumina microspheres, mix well, and transfer to the reaction Carry out hydrothermal treatment in the kettle, static reaction 36 h under 160 ℃. After the reaction, it was cooled to room temperature, filtered, washed twice with water and ethanol, and dried at 90°C for 14 h to obtain the LDH-based composite material containing nickel sludge.

[0032] The prepared LDH-based composite material containing nickel sludge has a specific surface area of 217.35 m 2 / g, the total pore volume is 0....

Embodiment 3

[0034] A preparation method of an LDH-based composite material containing nickel sludge, comprising the steps of:

[0035] a) Dry the sludge containing 8.43 wt% nickel at 180°C, grind and sieve to obtain a powder with a particle size of less than 100 μm, and calcinate at 800°C for 5 hours to obtain pretreated sludge;

[0036] b) Add 0.644 g of zinc sulfate, 22.548 g of pretreated sludge and 1.44 g of urea into 50 mL of deionized water in sequence, stir well, then add 0.419 g of flower-shaped alumina, mix well, transfer to the reactor for hydrothermal treatment , react statically at 220°C for 24 h, filter, wash with water and ethanol four times, and dry at 70°C for 16 h to obtain the LDH-based composite material containing nickel sludge.

[0037] The prepared LDH-based composite material containing nickel sludge has a specific surface area of 203.87 m 2 / g, the total pore volume is 0.39 cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com