Porous permeable geopolymer material as well as preparation method and application thereof

A technology of geopolymer and mineral powder, applied in the field of porous and permeable geopolymer materials and its preparation, can solve the problems of complex reaction wall engineering, long construction period, and large initial investment, so as to avoid the year-by-year decay of permeability coefficient, Improvement of processing capacity and improvement of adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

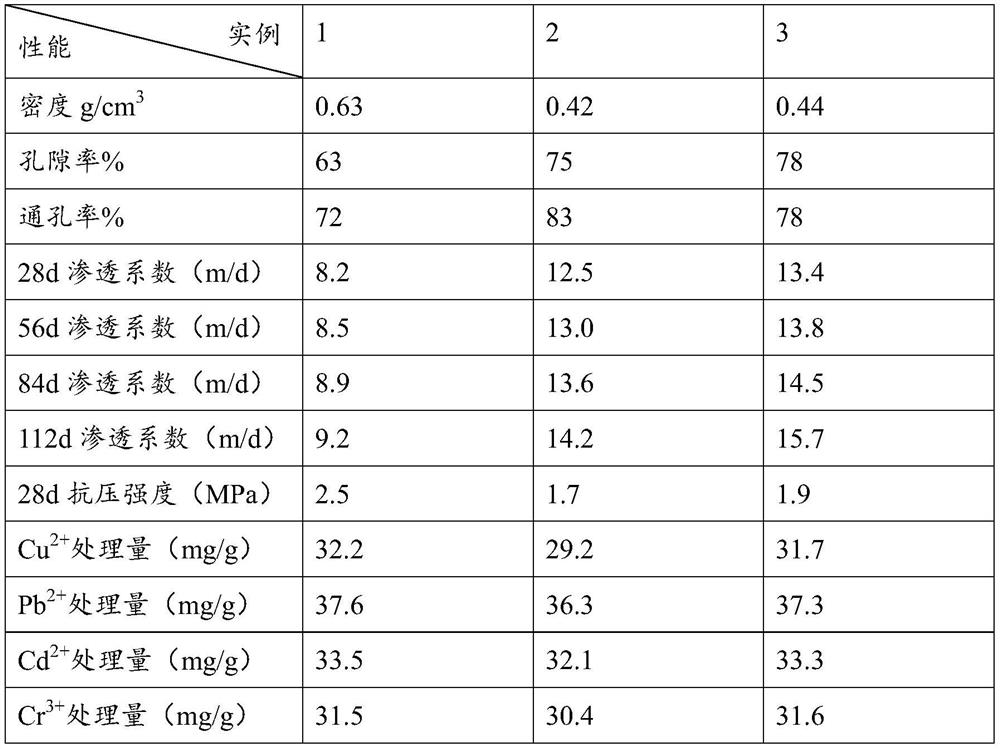

Examples

preparation example Construction

[0046] In one or some embodiments, a method for preparing a porous permeable gemmy is provided, comprising the step of: a natural mineral or solid waste or a mixture of a highly active silica aluminum or a mixture of the ingredients under an excitation agent The formation of the formation is made as a matrix material, and the pore agent is added to the matrix and fitted from degradation of fine particles, and it is necessary after curing;

[0047] Preferably, the natural mineral of the highly active silica aluminum is a genolite;

[0048] Preferably, the solid waste is fly ash, silicon ash;

[0049] Preferably, the excitation agent is sodium hydroxide or sodium silicate or mixtures, still more preferably sodium silicate;

[0050] Preferably, the self-degradation particles are aliphatic polyester PLA.

[0051] Preferably, the following steps:

[0052] The powder, excitation agent, and aperture mixture were mixed, and the self-degradation particles were mixed with the slurry, poured...

Embodiment 1

[0077] This embodiment provides a method for preparing a porous permeable gemmy material, comprising the steps of:

[0078] (1) Pipe Preparation: 45 pieces of powder coal ash according to the above ratios, 50 parts of height, 5 silica gray, stirred and uniform.

[0079] (2) Preparation of self-degradation of PLA particles: according to 50%, 30%, 15%, 5% of the proportion of molecular weights is 5 × 10, respectively, respectively 4 , 1 × 10 5 , 1.5 × 10 5 2 × 10 5 The multi-sets of molecular weight self-destruction materials were heated to 200 ° C, respectively, respectively, the active material, respectively, to each group of molecular weights, respectively, at this temperature at 100 rpm for 2 minutes to dispersion, and then make the material Cooling at room temperature under vacuum environments, grasted, over 200 mesh-300 mesh screen, and take material spare in this interval.

[0080] (3) mixing with sodium silicate excitation: The prepared powder is mixed with a sodium silicate...

Embodiment 2

[0085] This embodiment provides a method for preparing a porous permeable gemmy material, comprising the steps of:

[0086] (1) Pubic preparation: 45 parts of the slag, 50 parts of height, 5 silica fifth parts, stirred and mixed.

[0087] (2) Preparation of self-degradation of PLA particles: Press 40%, 30%, 25%, and 5%, the molecular weight is 5 × 10, respectively. 3 , 1 × 10 4 , 5 × 10 4 , 1 × 10 5 The multi-sets of molecular weight self-resolution materials are heated to 210 ° C, respectively, and the active material is equivalent to each group of molecular weights, and the mixture is stirred at 100 rpm at 100 rpm to be uniform, and the material is vacuum The environment is cooled to room temperature, grind, over 200 mesh-300 mesh screen, and take the material spare in this interval.

[0088] (3) mixing with sodium silicate excitation: The prepared powder is mixed with a sodium silicate solution having an analog to 1.5 in a ratio of 1: 0.5.

[0089] (4) mixing with a pore agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com