Sulfur-containing furandicarboxylic acid polyester and preparation method thereof

A technology of furandicarboxylic acid polyester and furandicarboxylic acid, which is applied in the field of biomass-based polymer materials and can solve the problems of high glass transition temperature and poor low temperature resistance of polyester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054]The preparation method of furandicarboxylic acid polyester monomer comprises the following steps:

[0055] Take 25g of furandicarboxylic acid, 100g of allyl chloride, and 75ml of triethylamine, and add them into a mixed solution of 75ml of acetone and 75ml of dimethylformamide. Place it in an oil bath at 90°C to reflux and stir for 12 hours. The specific reaction equation is as follows:

[0056]

[0057] Finally, dichloromethane and water were added for three extractions, and then the product was recrystallized by adding n-hexane after rotary evaporation to obtain a white powdery solid, which was a polyester monomer.

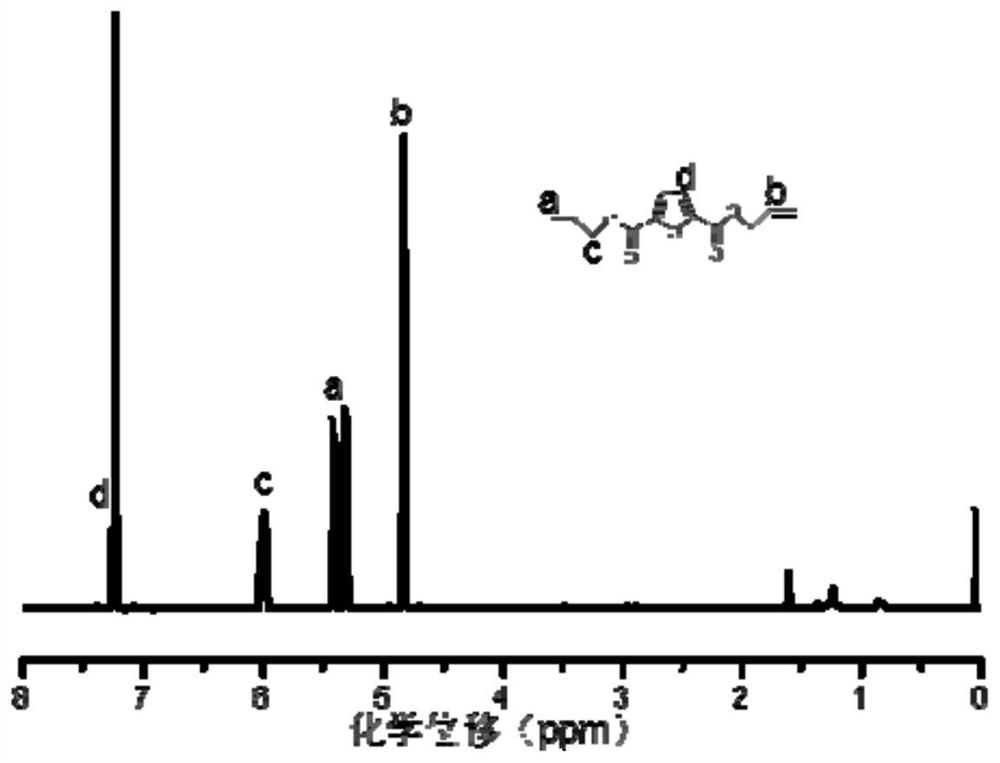

[0058] The 1H NMR spectrum of the polyester monomer 1 prepared in this embodiment is as follows figure 1 Shown, show the purity of obtained polyester monomer is very high. From figure 1 Peaks a at 5.3ppm and 5.4ppm and peak b at 4.8 show that allyl chloride is successfully incorporated into the monomer, which provides conditions for subsequent reacti...

Embodiment 2

[0060] The preparation method of furandicarboxylic acid polyester specifically comprises the following steps:

[0061] 1000 mg of the polyester monomer in Example 1, 656 mg of hexanedithiol, 27 mg of azobisisobutyronitrile and 10 mL of tetrahydrofuran were added to the reaction vessel. Argon was introduced for 20 minutes, and then the mixture was placed in an oil bath at 65°C for 12 hours. The specific reaction equation is as follows:

[0062]

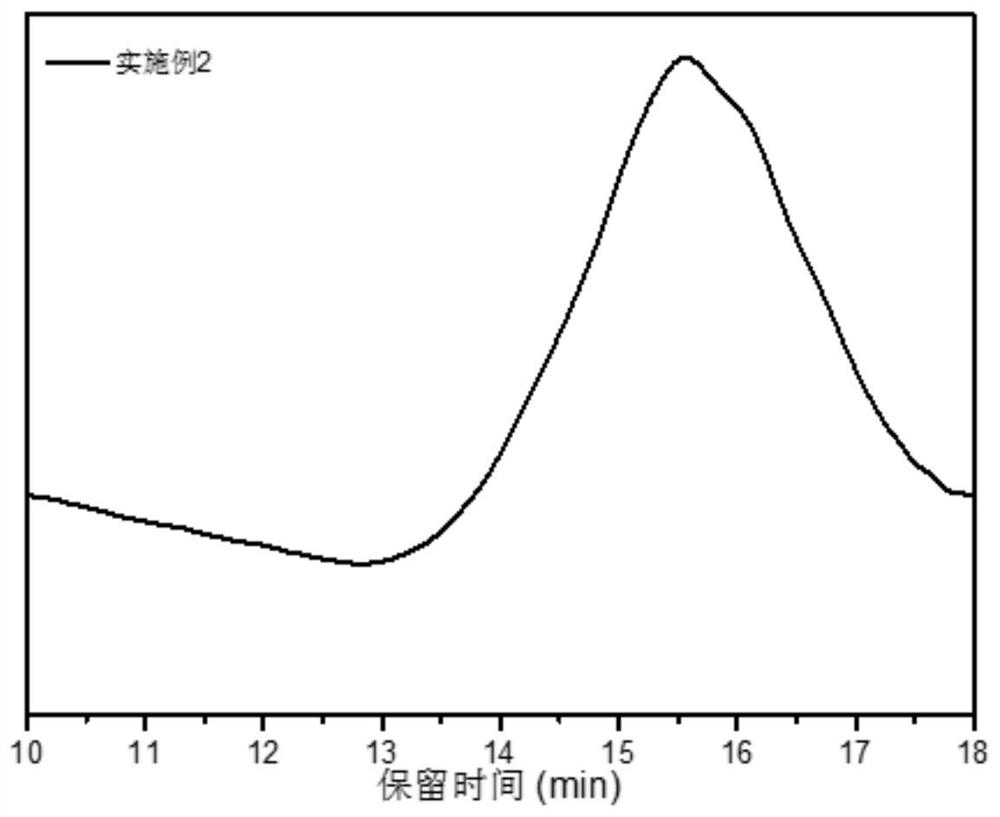

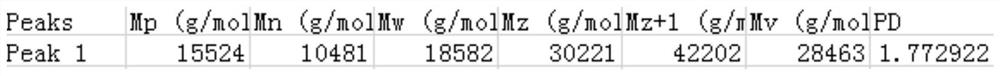

[0063] The raw material HS-R-SH in the equation (2) is the 1,6-hexanedithiol, and the S-R-S on the main chain of the product in the equation (2) is the disulfide R. Afterwards, a sulfur-containing furandicarboxylic acid polyester was obtained by methanol precipitation, which was named polyester 1.

Embodiment 3

[0065] The difference between this embodiment and embodiment 2 is that: the polyester 1 in embodiment 2 is stretched incrementally by straining the dumbbell-shaped spline of embodiment 2 at a constant stretching speed of 20mm / min, Each increment is 100% of the polymer deformation, recovery is performed after each increment is reached, when the force returns to 0, stretching is followed, and so on.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com