Negative ion water-based paint with fireproof function and preparation method thereof

A technology of water-based coatings and functional materials, applied in the direction of fire-resistant coatings, luminous coatings, polyurea/polyurethane coatings, etc., can solve the problems of high operating costs of exhaust systems, white holes, insufficient lighting brightness of road tunnels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

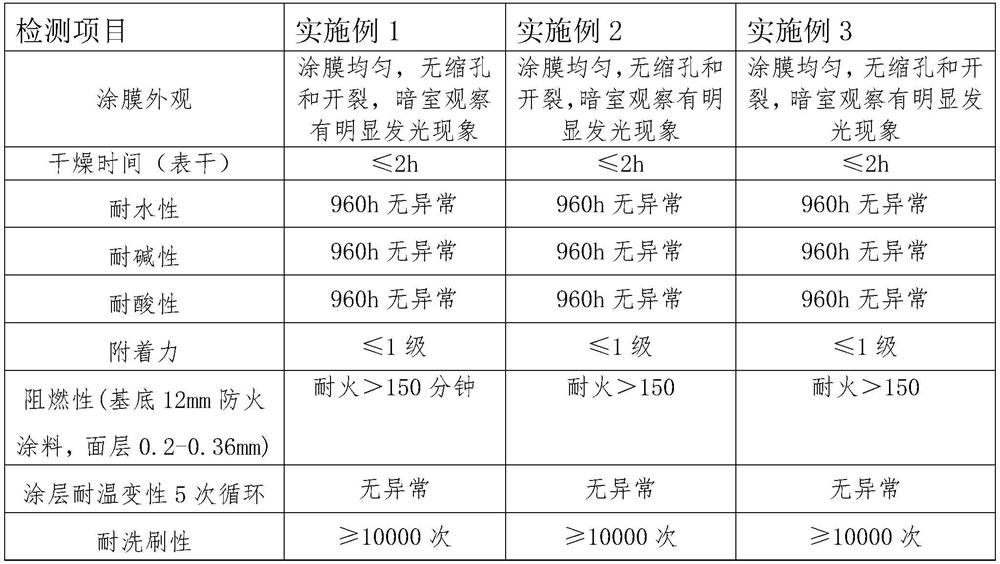

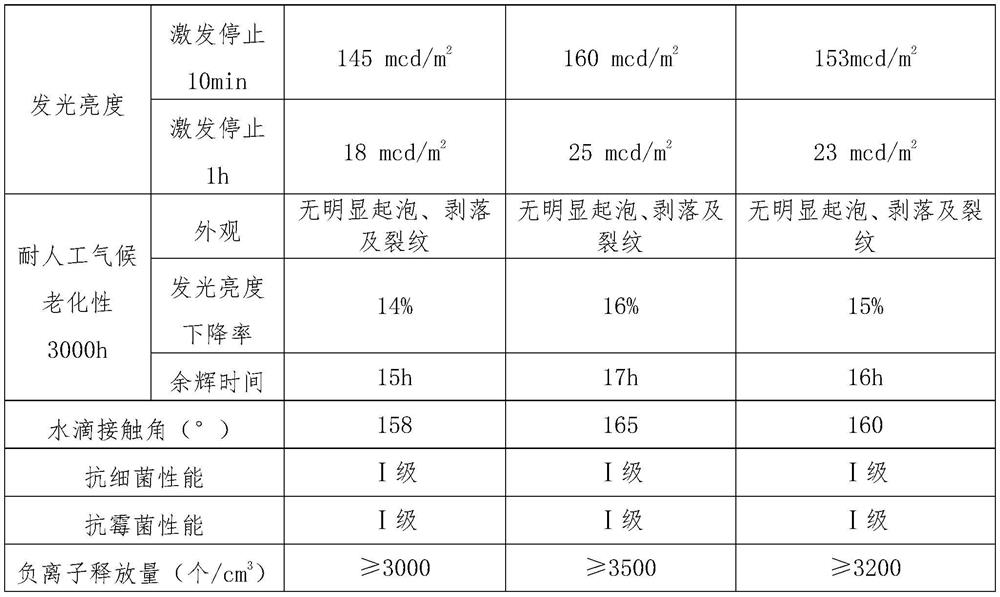

Examples

preparation example Construction

[0034] Specifically, the preparation method of the functional material includes the following steps:

[0035] Keep the connecting pipes of the ultrasonic reactor in a sealed state, vacuumize and pass nitrogen;

[0036] Then add a solvent of 80% formula to the ultrasonic reactor, start the ultrasonic stirring device, slowly add nano-rare earth aluminate, nano-anion powder, and nano-titanium dioxide into the solvent, and ultrasonically stir for 30 minutes;

[0037] Monomer materials trifluoroethyl methacrylate, vinylidene chloride, vinyl acetate, ethyl methacrylate, butyl acrylate, isobornyl methacrylate, AH-171 vinyltrimethoxysilane, allyl sulfonate Sodium acid is stirred evenly with a high-speed disperser; the initiator dimethyl azobisisobutyrate is dissolved in a solvent with a formula volume of 20% for stand-by;

[0038] Raise the temperature in the reaction kettle to 80°C, and add the monomer and 80% initiator solution dropwise at the same time, and finish dropping in 3-4 ...

Embodiment 1

[0049] A kind of negative ion water-based paint with fireproof function, comprises the following components by weight parts:

[0050]35 parts of water-based polyurea resin, 12 parts of water-based fluorocarbon resin, 8 parts of water-based vinyl resin, 18 parts of functional materials, 5 parts of flame retardant, 8 parts of additives, 50 parts of water;

[0051] Wherein the functional material is a water-based organic coating material, including the following components by weight percentage:

[0052] 20 parts of nano-rare earth aluminate, 10 parts of nano-anion powder, 5 parts of nano-titanium dioxide, 1 part of trifluoroethyl methacrylate, 1 part of vinylidene chloride, 1 part of vinyl acetate, 6 parts of ethyl methacrylate, butyl acrylate 6 parts of ester, 2 parts of isobornyl methacrylate, 1 part of AH-171 vinyltrimethoxysilane, 1 part of sodium allyl sulfonate, 25 parts of propylene glycol methyl ether, 30 parts of isopropanol, azobisiso 2 parts of dimethyl butyrate.

Embodiment 2

[0054] A kind of negative ion water-based paint with fireproof function, comprises the following components by weight parts:

[0055] 38 parts of water-based polyurea resin, 18 parts of water-based fluorocarbon resin, 10 parts of water-based vinyl resin, 22 parts of functional materials, 8 parts of flame retardant, 10 parts of additives, 60 parts of water;

[0056] Wherein the functional material is a water-based organic coated luminescent material, including the following components by weight percentage:

[0057] 20 parts of nano-rare earth aluminate, 10 parts of nano-anion powder, 5 parts of nano-titanium dioxide, 1 part of trifluoroethyl methacrylate, 1 part of vinylidene chloride, 1 part of vinyl acetate, 6 parts of ethyl methacrylate, butyl acrylate 6 parts of ester, 2 parts of isobornyl methacrylate, 1 part of AH-171 vinyltrimethoxysilane, 1 part of sodium allyl sulfonate, 25 parts of propylene glycol methyl ether, 30 parts of isopropanol, azobisiso 2 parts of dimethyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com