Low-temperature denitration catalyst and preparation method thereof

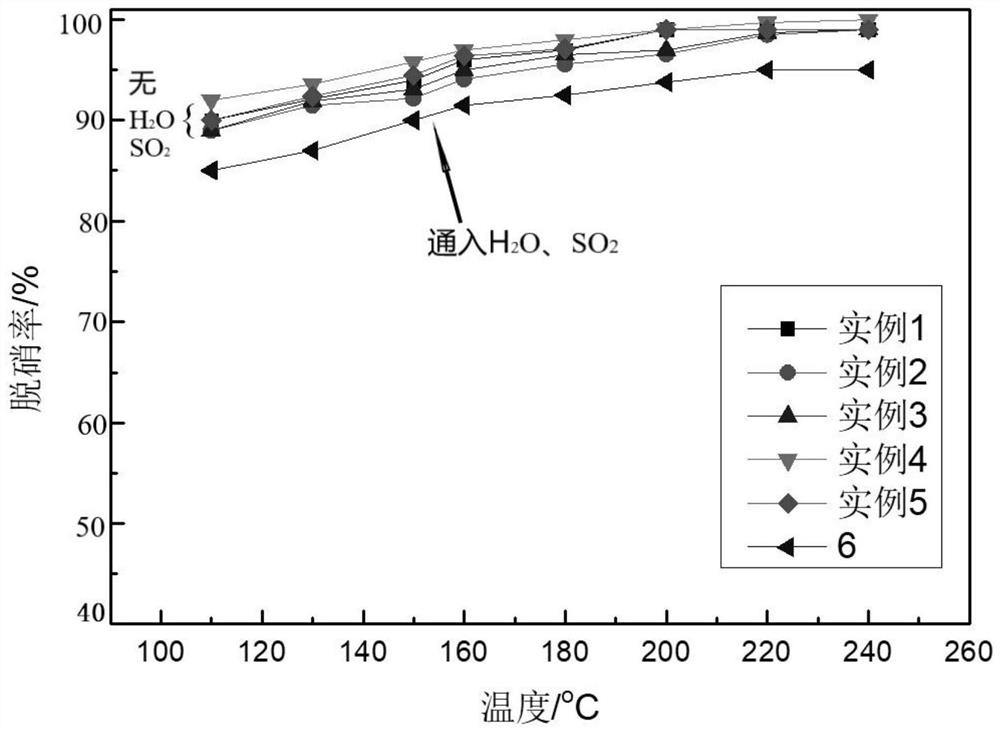

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., to achieve excellent denitrification performance, improved anti-sulfur and anti-water poisoning ability, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] (1) Preparation of catalyst active component niobium manganese metal oxide precursor solution

[0031] Weigh 8.34g of niobium chloride and 5.52g of manganese nitrate solution, respectively add deionized water and stir to dissolve to a clear and transparent solution to obtain a niobium manganese metal oxide precursor solution;

[0032] (2) Preparation of co-catalyst precursor solution

[0033] Weigh 3.15g of barium hydroxide octahydrate, 21.7g of cerium nitrate hexahydrate, and 15.6g of ferric nitrate nonahydrate, add deionized water and stir to dissolve to a clear and transparent solution to prepare a co-catalyst precursor solution;

[0034] (3) Preparation of catalyst carrier

[0035] Weigh 60g of silica, fully ball mill, select silica between 1000-1200 mesh;

[0036] Weigh 100g titanium dioxide, 5g pseudo-boehmite, mix with the silicon dioxide powder prepared above, stir for 1 hour until uniform, titanium dioxide: silicon dioxide: pseudo-boehmite mass ratio is 1:0.6...

example 2

[0045] (1) Preparation of catalyst active component niobium manganese metal oxide precursor solution

[0046] Weigh 0.06g of niobium chloride and 64.76g of manganese acetate solution, respectively add deionized water and stir to dissolve to a clear and transparent solution to obtain a barium niobium manganese metal oxide precursor solution;

[0047] (2) Preparation of co-catalyst precursor solution

[0048] Weigh 0.58g barium hydroxide octahydrate, 043g lanthanum nitrate hexahydrate, 0.91g copper nitrate trihydrate, 0.81g ammonium molybdate, add deionized water and stir to dissolve to a clear and transparent solution to obtain a co-catalyst precursor solution;

[0049] (3) Preparation of catalyst carrier

[0050] Weigh 30g of silica, fully ball mill, select silica between 1000-1200 mesh;

[0051] Weigh 100g titanium dioxide, 10g pseudo-boehmite, mix with the silicon dioxide powder prepared above, stir for 2 hours until uniform, titanium dioxide: silicon dioxide: pseudo-boehm...

example 3

[0060] (1) Preparation of catalyst active component niobium manganese metal oxide precursor solution

[0061] Weigh 2.7g of niobium chloride and 35.79g of manganese nitrate solution, respectively add deionized water and stir to dissolve to a clear and transparent solution to obtain a barium niobium manganese metal oxide precursor solution;

[0062] (2) Preparation of co-catalyst precursor solution

[0063] Weigh 0.31g barium hydroxide octahydrate and 4.34g cerium nitrate hexahydrate, add an appropriate amount of deionized water and stir to dissolve to a clear and transparent solution to obtain a co-catalyst precursor solution;

[0064] (3) Preparation of catalyst carrier

[0065] Weigh 40g of silica, fully ball mill, select silica between 1000-1200 mesh;

[0066] Weigh 100g titanium dioxide, 10g pseudo-boehmite, mix with the silicon dioxide powder prepared above, stir for 1 hour until uniform, titanium dioxide: silicon dioxide: pseudo-boehmite mass ratio is 1:0.4:0.1 ;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com