Organic transition metal compound, preparation method and method for forming transition metal-containing thin film

A transition metal and compound technology, applied in the synthesis of metal compounds and thin films, can solve problems such as difficult to obtain transition metal organic compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

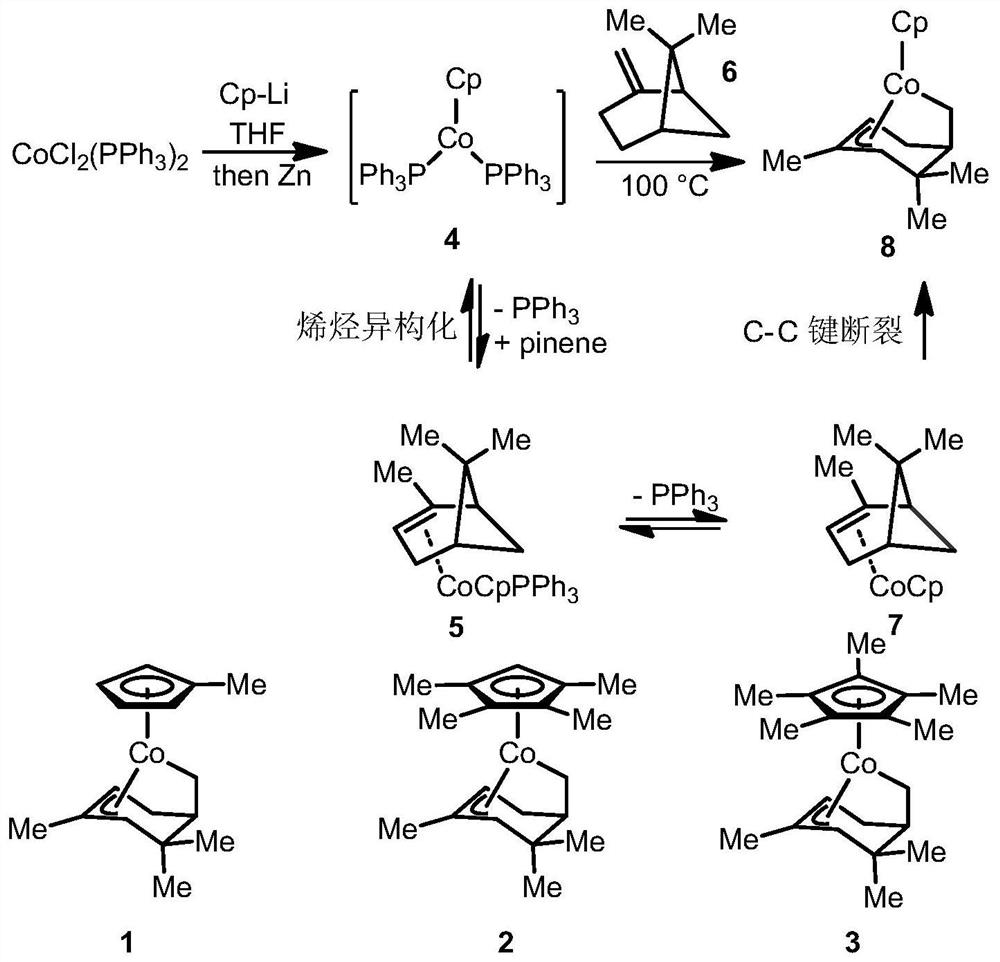

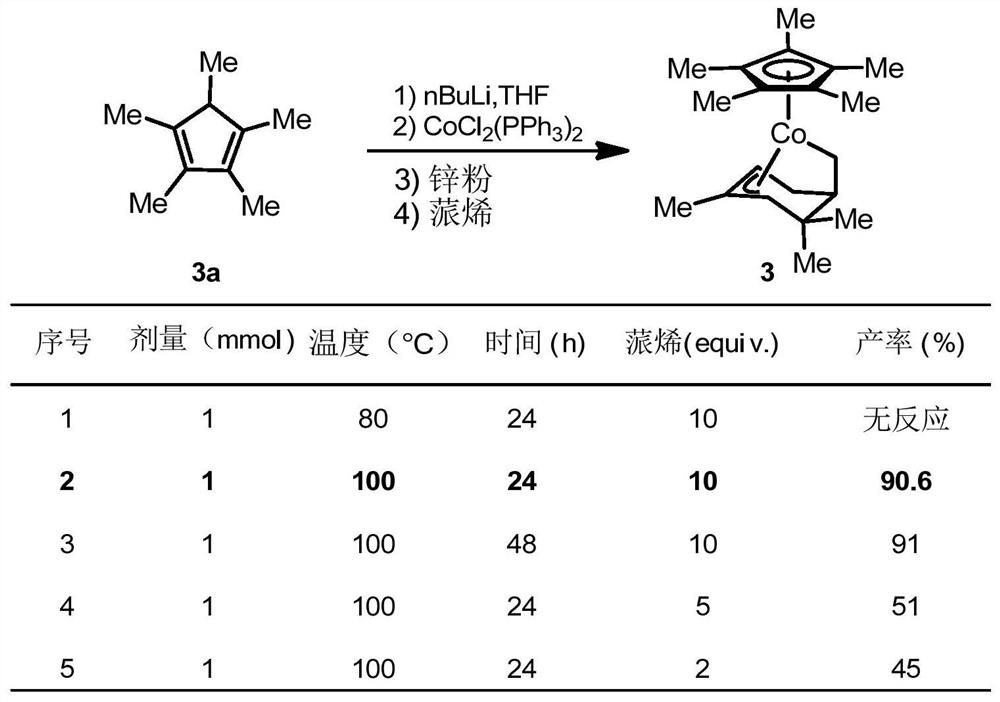

[0066] Based on this, the embodiment of the present invention provides the preparation method of the organic cobalt metal compound as described above, the method includes the steps of: CoCl 2 (PPh 3 ) 2 The low-priced cobalt compound is obtained by in-situ reduction under the action of zinc powder, and the low-priced cobalt compound reacts with β-pinene or C-C bond oxidative addition to obtain the organic cobalt metal compound.

[0067] Specifically, the first is to use CoCl 2 with twice the molar amount of PPh 3 The reaction gives CoCl which is stable to air at room temperature and pressure 2 (PPh 3 ) 2 . Then, this compound and cyclopentadienyllithium compound undergo lithium halogen exchange reaction at low temperature to obtain Cp-CoCl(PPh 3 ) 2 intermediate product, see figure 1 shown. Then, directly add zinc powder and excess pinene into the reaction system, and react at 100° C. for 24 hours. After the reaction, waste solids and volatile solvents can be remove...

application example 1

[0076] By using chelated η 1 , η 3 , η 5 - cobalt(III) organometallic compound (compound 1) as cobalt precursor and O 2 As a co-reactant, thin films of cobalt oxide were deposited in a home-made tubular atomic layer deposition reactor. Planar SiO 2 / Si substrates were used to study the growth behavior of the films. The cobalt precursor was kept in a bubbler and heated to 50°C to provide sufficient vapor pressure for deposition. The precursor vapor is transported to the deposition chamber with the aid of pure Ar gas (via an inert gas purifier) as a carrier gas. 30 sccm of co-reactant O 2 The gas is delivered to the atomic layer deposition reactor, and the plasma O 2 The length of time is set to 10s. Plasma O 2 The power setting is 90W. During the purge, the argon gas was about 0.4 Torr.

[0077] By using chelated η 1 , η 3 , η 5 - cobalt(III) organometallic compound (compound 1) as cobalt precursor and O 2 As a co-reactant, thin films of cobalt oxide were depos...

application example 2

[0079] By using chelated η 1 , η 3 , η 5 - cobalt(III) organometallic compound (compound 1) as cobalt precursor and H 2 S was used as a co-reactant to deposit cobalt sulfide thin films in a home-made tubular atomic layer deposition reactor. Planar SiO 2 / Si substrates were used to study the growth behavior of the films. The cobalt precursor was kept in a bubbler and heated to 50°C to provide sufficient vapor pressure for deposition. The precursor vapor is transported to the deposition chamber with the aid of pure Ar gas (via an inert gas purifier) as a carrier gas. 30sccm of co-reactant H 2 S gas is delivered to the atomic layer deposition reactor, and the plasma H 2 The length of the S time is set to 10s. Plasma H 2 The power of the S is set to 90W. During the purge, the argon gas was about 0.4 Torr. The obtained cobalt sulfide films were characterized in Figure 8Among them, a-c is the X-ray photoelectron spectrum of the thin film in the case of atomic layer de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com