All-solid-state self-repairing ionic conductor and preparation method thereof, and ion device

An ionic conductor and self-repairing technology, applied in the direction of conductors, non-metallic conductors, organic material conductors, etc., can solve problems that affect the use experience and effect of ionic devices, ionic liquid leakage, and conductance drop of ionic devices, etc., to achieve convenient optical ionic devices Field, high environmental stability, avoid volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] A method for preparing an all-solid self-repairing ion conductor, comprising:

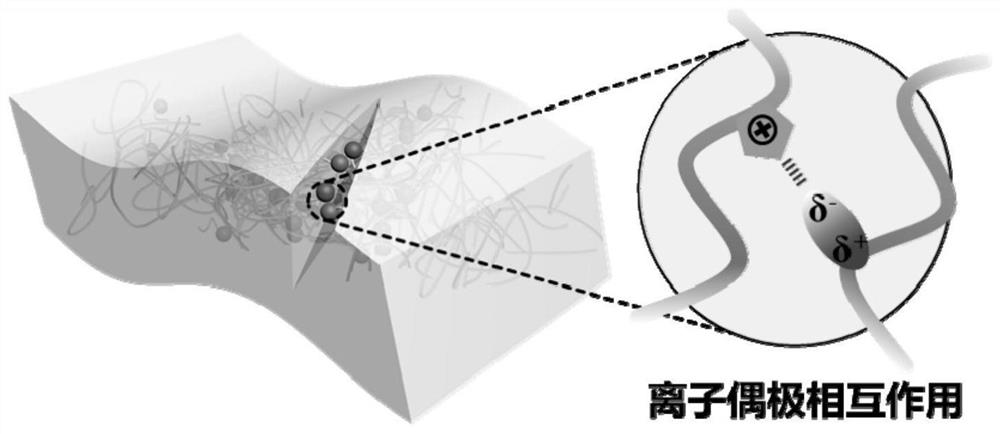

[0058] mixing raw materials including dipole monomers, ionic liquid monomers and initiators, and performing a polymerization reaction to obtain the all-solid-state self-healing ionic conductor;

[0059] The dipole monomer includes one or more of acrylate monomers, propionamide monomers, halogen-containing olefin monomers, styrene monomers and vinyl monomers; the ionic liquid Monomers include imidazole ionic liquid monomers, pyridine ionic liquid monomers, pyrrole ionic liquid monomers, piperidine ionic liquid monomers, quaternary ammonium salt ionic liquid monomers and quaternary phosphonium ionic liquid monomers One or more; the initiator includes one or more of a photoinitiator, a thermal initiator and a redox initiator.

[0060] In an optional embodiment, the acrylate monomers include methyl acrylate, ethyl acrylate, butyl acrylate, octyl ethyl acrylate, trifluoroethyl acrylate, tetraflu...

Embodiment 1

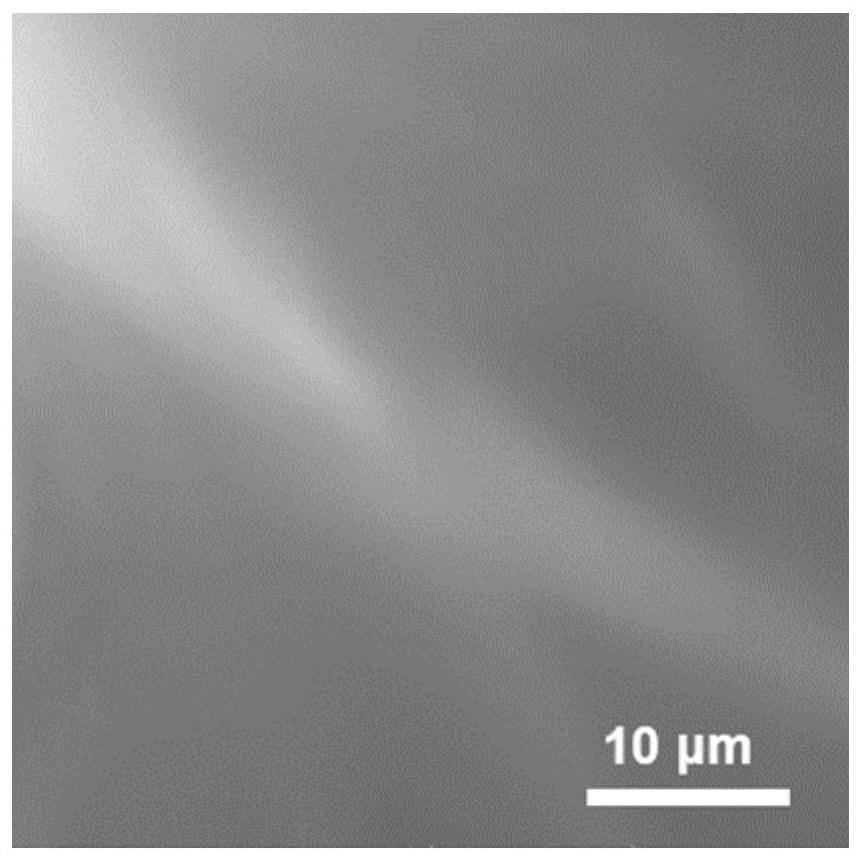

[0083] 0.6g dipolar monomer hexafluorobutyl acrylate (FBA), 0.4g ionic liquid monomer 1-(6-(acryloyloxy)-hexyl)-3-methylimidazole bistrifluoromethylsulfonyl The amine salt ([EIC6A][TFSI]) was mixed with 3.4 mg of photoinitiator 184 (1-hydroxy-cyclohexyl-phenyl ketone), and stirred well to form a precursor liquid. Put the homogeneously mixed precursor liquid into the vacuum box, vacuum degree 0.1bar, degas for 30s. Inject the degassed precursor liquid into the assembled glass sheet-silica gel pad-glass sheet sandwich cavity (the glass sheet is coated with a release film), and put it into a vacuum cross-linking box. Put the mold that has been injected with the precursor fluid into the ultraviolet cross-connection box, and the power density is 50mW / cm 2 , Cross-linking for 30min. After the reaction is over, the glass mold is disassembled, and the self-healing intrinsically conductive ion conductor is taken out. The obtained ionic conductor was placed in a vacuum drying oven at...

Embodiment 2

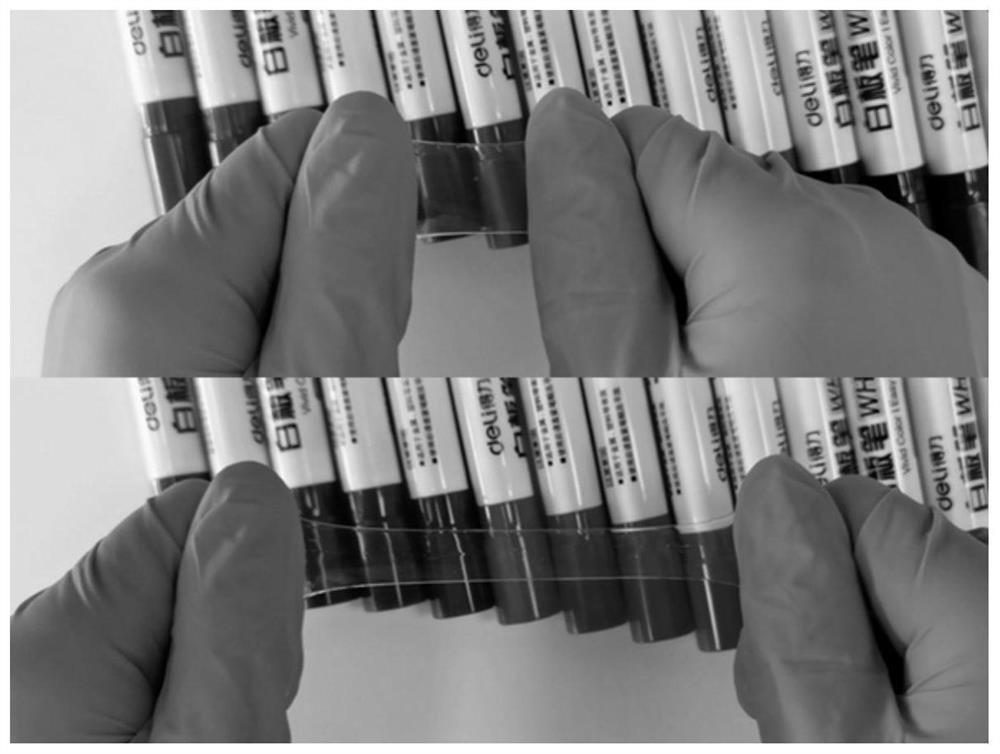

[0085] Mix 0.7g FBA, 0.3g ionic liquid monomer [EIC6A][TFSI] and 3.6mg photoinitiator 184, and stir well to form a precursor liquid. Put the homogeneously mixed precursor liquid into the vacuum box, vacuum degree 0.1bar, degas for 30s. Inject the degassed precursor liquid into the assembled glass sheet-silica gel pad-glass sheet sandwich cavity (the glass sheet is coated with a release film), and put it into a vacuum cross-linking box. Put the mold that has been injected with the precursor fluid into the ultraviolet cross-connection box, and the power density is 50mW / cm 2 , Cross-linking for 30min. After the reaction is over, the glass mold is disassembled, and the self-healing intrinsically conductive ion conductor is taken out. The obtained ionic conductor was placed in a vacuum drying oven at 50°C for 6 hours under vacuum degassing, and the [EIC6A][TFSI]-co-PFBA polyionic liquid self-repairing intrinsically conductive ionic conductor was obtained after deodorization, whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com