A kind of preparation method of metal chloride-graphite intercalation compound electrode material and application thereof

A graphite intercalation and chloride technology, applied in active material electrodes, negative electrodes, battery electrodes, etc., can solve problems such as chlorine toxicity, and achieve the effects of large intercalation amount, simple process and stable intercalation structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

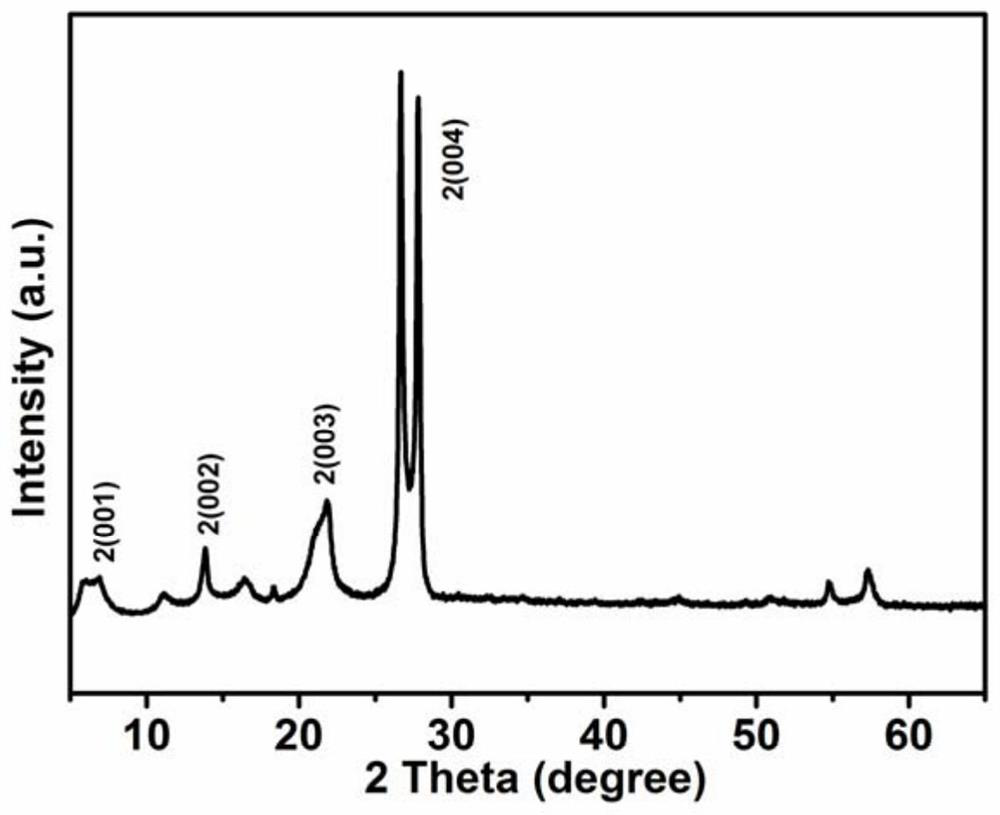

[0016] Weigh 0.2g of graphite powder and 1.0g of bismuth trichloride, add them into an agate mortar, grind them uniformly for 5 minutes, and then transfer them to a reaction kettle. Add 0.8 mL of sulfonyl chloride to the reaction kettle. The above operations are completed in a glove box, and then Take the reaction kettle out of the glove box and put it into a muffle furnace for the reaction. The temperature is from room temperature to 5 °C min. -1 The heating rate was raised to 450 °C, and the temperature was kept constant for 24 h. After the reaction, the product was taken out, washed with absolute ethanol for 3 times, and filtered with suction. The filter cake was placed in a vacuum drying box and dried at 80 °C for 10 h to obtain trichloride. Bismuth-graphite intercalation compounds. Its X-ray diffraction pattern, such as figure 1 It can be seen that, compared with the characteristic diffraction peak of the (002) crystal plane of graphite, the bismuth trichloride-graphite ...

Embodiment 2

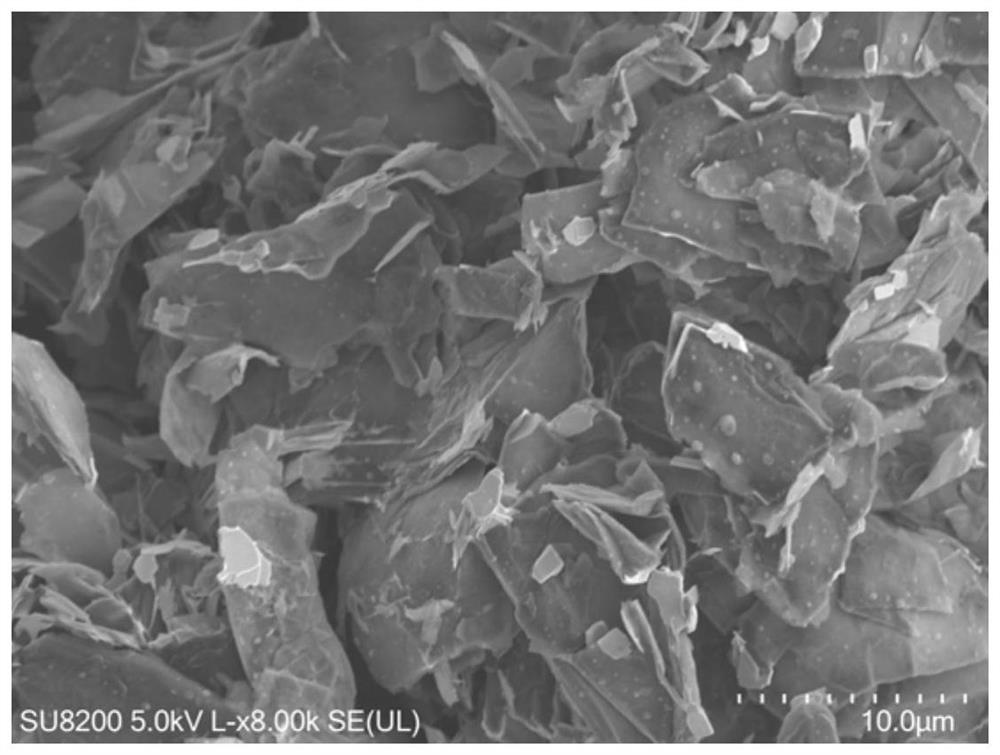

[0018] Weigh 0.2g of graphite powder and 1.0g of bismuth trichloride, add them into an agate mortar, grind them uniformly for 5 minutes, and then transfer them to a reaction kettle, and add 1.5 mL of sulfonyl chloride to the reaction kettle. The above operations are completed in a glove box, and then Take the reaction kettle out of the glove box and put it into a muffle furnace for the reaction. The temperature is from room temperature to 5 °C min. -1 The heating rate was raised to 200 °C, and the temperature was kept constant for 10 h. After the reaction, the product was taken out, washed with anhydrous ethanol for 3 times, and then suction filtered. The filter cake was placed in a vacuum drying box and dried at 80 °C for 10 h to obtain trichloride. Bismuth-graphite intercalation compounds. Its scanning electron microscope photos, such as figure 2 It can be seen that the bismuth trichloride-graphite intercalation compound shows a typical flake structure, which is similar to...

Embodiment 3

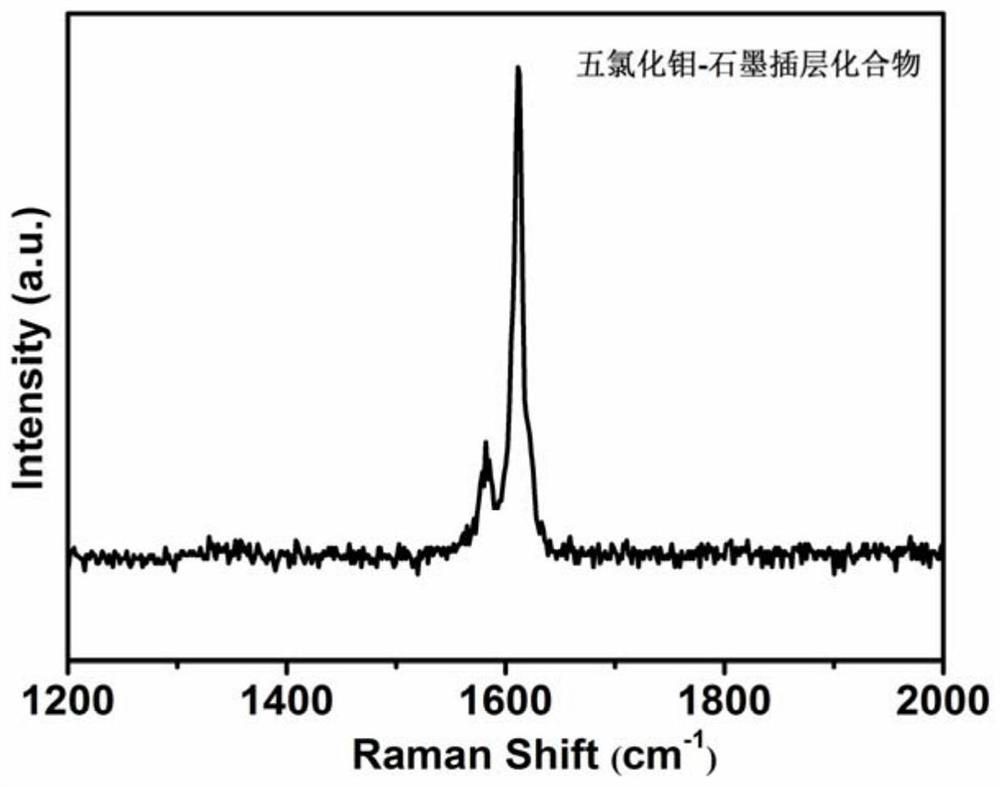

[0020] Weigh 0.5g of graphite powder and 2.5g of tungsten hexachloride, add them into an agate mortar, grind them uniformly for 5 minutes, and then transfer them to the reaction kettle, and add 0.8 mL of sulfonyl chloride to the reaction kettle. The above operations are completed in a glove box, and then Take the reaction kettle out of the glove box and put it into a muffle furnace for the reaction. The temperature is from room temperature to 5 °C min. -1 The heating rate was raised to 350 °C, and the temperature was kept constant for 10 h. After the reaction was completed, the product was taken out, washed with absolute ethanol for 5 times, and then suction filtered. Tungsten-graphite intercalation compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com