Preparation method and application of radix puerariae resistant starch

A technology of kudzu root starch and resistant starch, which is applied in the field of food processing, can solve the problems of low content of resistant starch, low utilization rate of raw materials, and complicated preparation process, so as to improve the content and quality, increase the effect of lowering blood sugar and blood fat, The effect of alleviating insulin resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a method for preparing kudzu root resistant starch, comprising the following steps:

[0043] Pre-gelatinizing Pueraria starch milk to obtain pasty Pueraria starch;

[0044] Carry out autoclaving treatment to described pasty kudzu root starch, obtain autoclaved kudzu root starch;

[0045] Debranching treatment is carried out on the pressurized kudzu starch by using a debranching enzyme to obtain kudzu resistant starch; the temperature of the debranching treatment is 35-45° C., and the time is 2-6 hours.

[0046] In the invention, the kudzu root starch milk is pregelatinized to obtain pasty kudzu root starch. The present invention preferably uses sodium acetate to dissolve pueraria starch to prepare pueraria starch milk; in the present invention, the concentration of sodium acetate is preferably 0.1~0.5M, more preferably 0.2M; the pH of the sodium acetate is preferably 4~7, further Preferably 5.2. In the present invention, the kudzu root starch m...

Embodiment 1

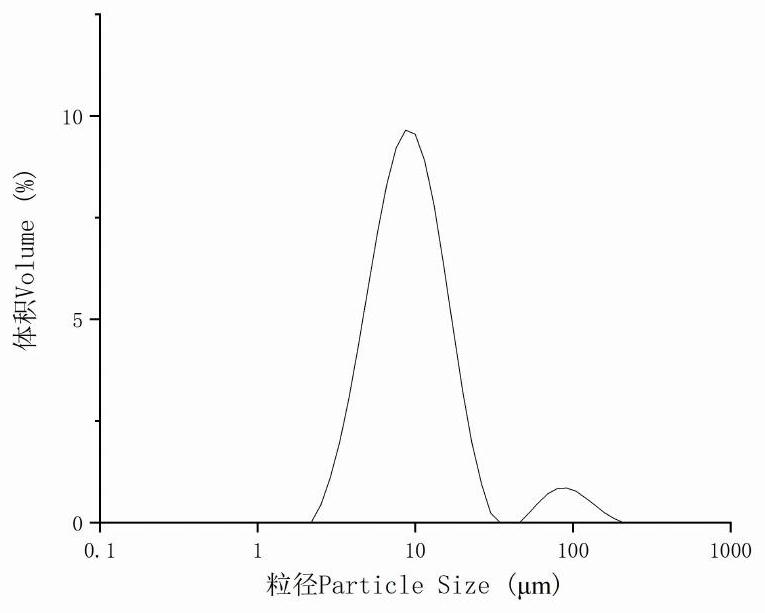

[0071] according to Image 6 The process prepares autoclave-enzymolysis kudzu root resistant starch (DA-KRS), specifically, weigh 100g kudzu root starch (KS), disperse it in 0.2M sodium acetate (pH 5.2) solution, and prepare a mass concentration of 15 % starch milk, pre-gelatinized at 95°C for 30 minutes, put into an autoclave, and autoclave at 121°C for 30 minutes.

[0072]After the autoclave treatment, take it out, cool it naturally to 40°C, adjust the pH to 4.5, add 60U / g pullulanase, and enzymatically treat it at 40°C for 4h. Then, the enzyme was extinguished at 95°C for 15 minutes, the sample was taken out and cooled to room temperature, aged at 4°C for 24 hours, dried at 60°C for 12 hours, crushed, and passed through a 120-mesh sieve to obtain autoclave-enzymolysis kudzu root resistant starch (DA-KRS).

Embodiment 2

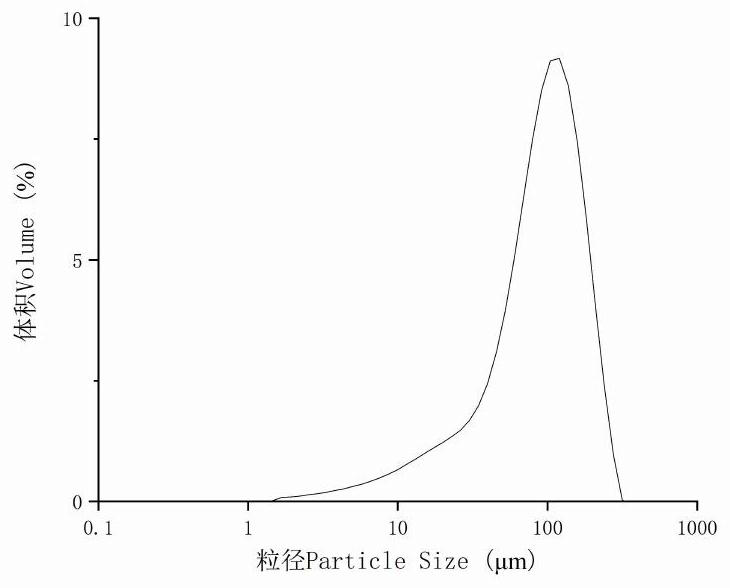

[0074] according to Figure 7 Prepare the autoclave-enzymolysis-purified kudzu root resistant starch (P-KRS) according to the process. Specifically, weigh 50 g of the autoclave-enzymolysis kudzu root resistant starch in Example 1, and use citric acid buffer (0.135M, pH =2) Prepare starch milk with a mass concentration of 15%, add 10 mL of pepsin (400 U / mL), shake in a constant temperature water bath at 40°C for 1 hour. Then adjust the pH to 7, add 10 mL of high temperature resistant α-amylase (400 U / mL), and shake in a constant temperature water bath at 40°C for 30 minutes. Then adjust the pH to 4.5, add 0.6 g of glucoamylase (100,000 U / g), shake in a constant temperature water bath at 60°C for 1 hour. Inactivate the enzyme at high temperature, remove the supernatant by centrifugation, wash the autoclave-enzymolysis pueraria resistant starch precipitate obtained after sterilization with 95% ethanol, remove the supernatant by centrifugation, and repeatedly wash with 95% ethano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com