Uranium adsorbent and preparation method and application thereof

An adsorbent and organic solvent technology, applied in the field of uranium adsorbent and its preparation, can solve the problems of limited industrial application and promotion, low adsorption capacity, poor mechanical strength, etc., and achieves low cost, high adsorption capacity, and increased hydrophilicity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of uranium adsorbent, comprising the following steps:

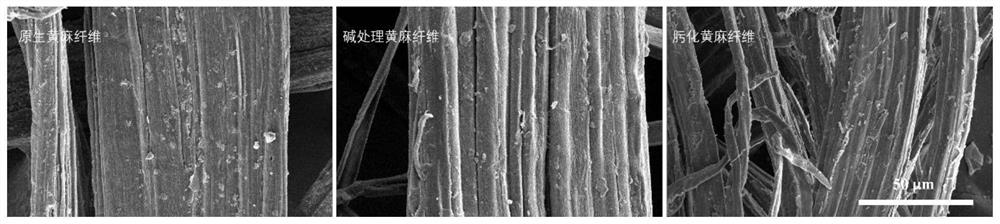

[0031] The inorganic alkaline solution is mixed with the jute fiber for pretreatment to obtain the pretreated jute fiber matrix material;

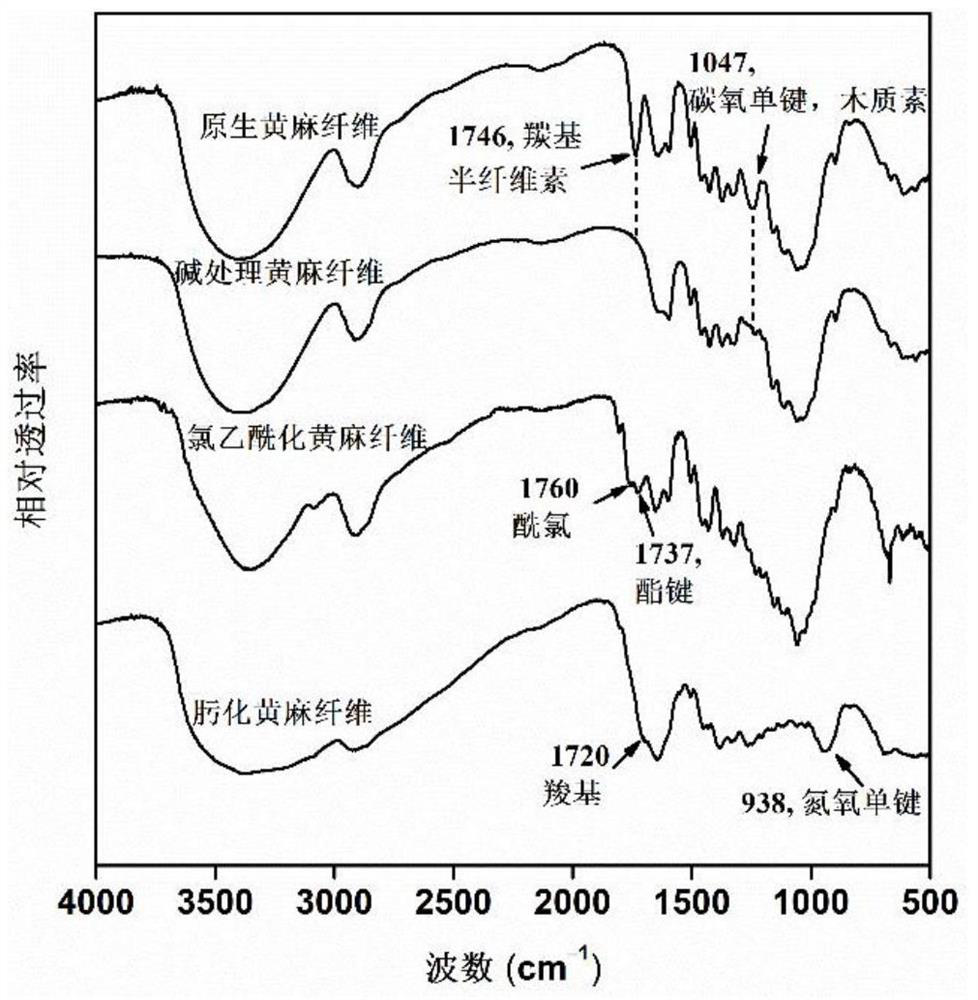

[0032] Under an inert atmosphere, the pretreated jute fiber matrix material, acid chloride derivatives and organic solvents are mixed for chloroacetylation to obtain chloroacetylated jute fibers;

[0033] Under an inert atmosphere, mix hydroxylamine hydrochloride, an inorganic base and an organic solvent, heat, then mix with polyacrylonitrile for oximation to obtain oximated polyacrylonitrile;

[0034] The chloroacetylated jute fiber, the oximated polyacrylonitrile and an organic solvent are mixed for grafting reaction to obtain the uranium adsorbent.

[0035] In the present invention, unless otherwise specified, the raw materials used are all commercially available products in this field.

[0036] The invention mixes the inorganic ...

Embodiment 1

[0074] Add 45mL of deionized water and 5.00g of sodium hydroxide to a 250mL three-neck flask to configure a 10wt% alkali solution, immerse 4.55g of jute fiber in the above alkali solution, and keep the mixture at 50°C for 2 hours. After fully washing the jute fiber with deionized water, dry it in a blast drying oven for later use.

[0075] In an inert atmosphere, dissolve 100mmol of hydroxylamine hydrochloride in 100mL of N,N-dimethylacetamide. After the solid is completely dissolved, add 100mmol of sodium hydroxide to the mixture, and stir well to form a suspension. Subsequently, the temperature of the mixed liquid was raised to 60°C, and then 85 mesh, 120 mmol polyacrylonitrile powder was gradually added to the above mixed liquid, reacted for 6 hours at a stirring speed of 500 r / min, and then cooled to room temperature. Finally, the mixed solution was centrifuged to remove insoluble matter, and the obtained supernatant was directly poured into deionized water to precipitate ...

Embodiment 2

[0085] Add 45mL of deionized water and 24.23g of potassium hydroxide to a 250mL three-necked flask to configure a 35wt% alkali solution, immerse 12.12g of jute fibers in the above alkali solution, and keep the mixture at 90°C for 12 hours. After fully washing the jute fiber with deionized water, dry it in a blast drying oven for later use.

[0086] In an inert atmosphere, dissolve 100mmol of hydroxylamine hydrochloride in 100mL of N,N-dimethylformamide. After the solid is completely dissolved, add 100mmol of sodium hydroxide to the mixture, and stir well to form a suspension. Subsequently, the temperature of the mixed liquid was raised to 100°C, and then 150 mesh, 200 mmol polyacrylonitrile powder was gradually added to the above mixed liquid, reacted for 12 hours at a stirring speed of 1000 r / min, and then cooled to room temperature. Finally, the mixed solution was centrifuged to remove insoluble matter, and the obtained supernatant was directly poured into deionized water to...

PUM

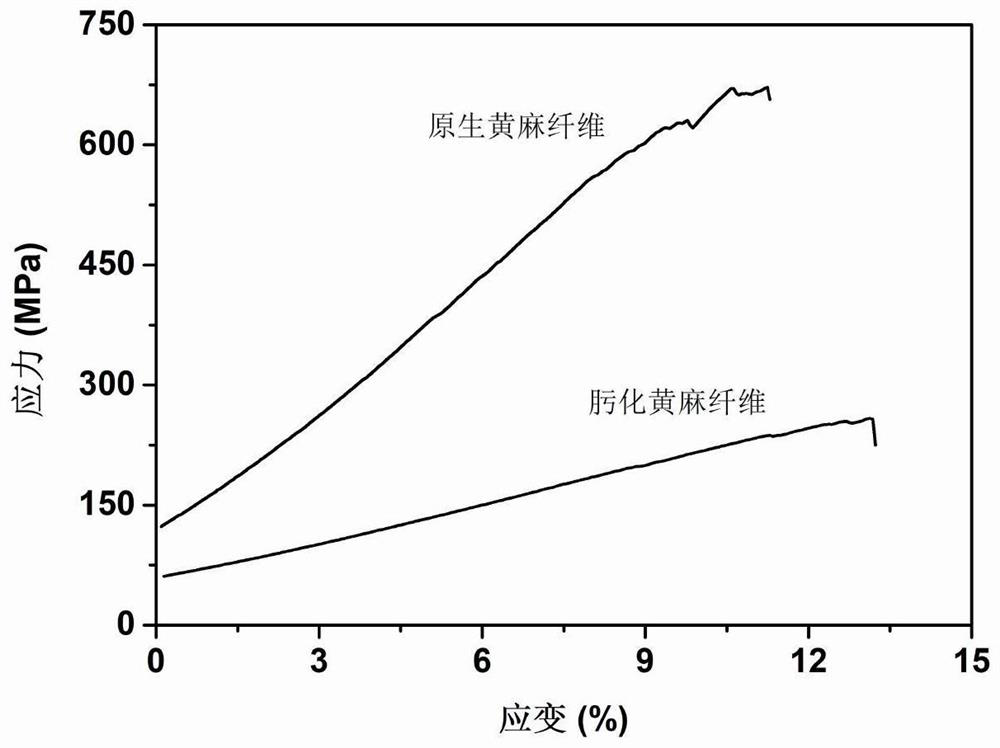

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com