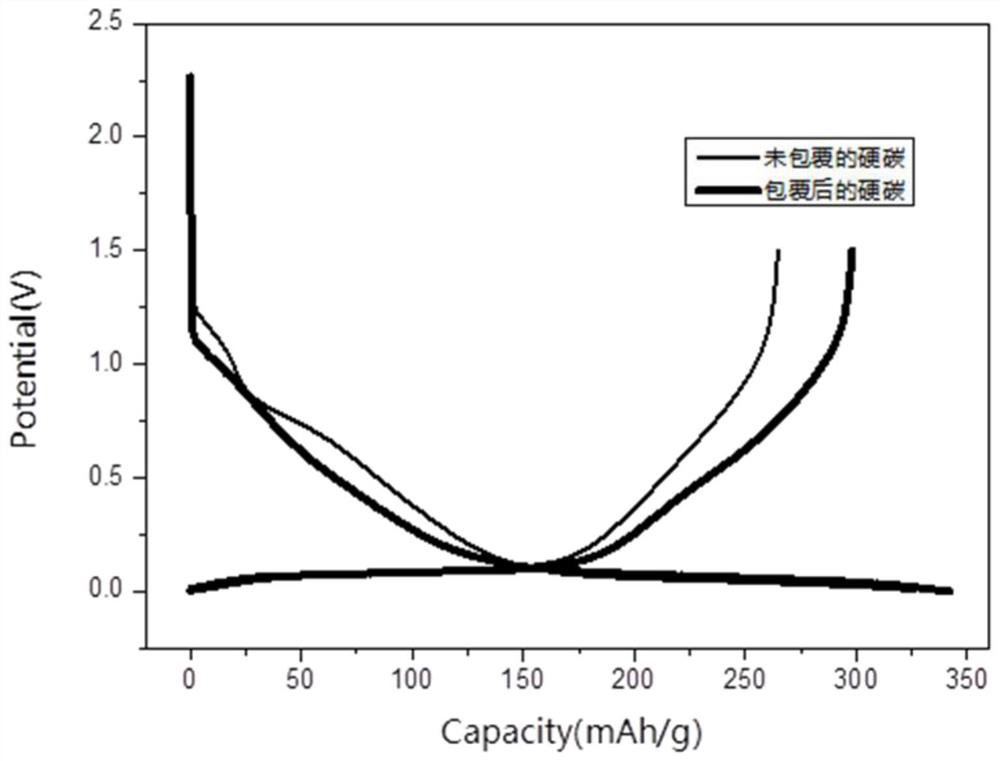

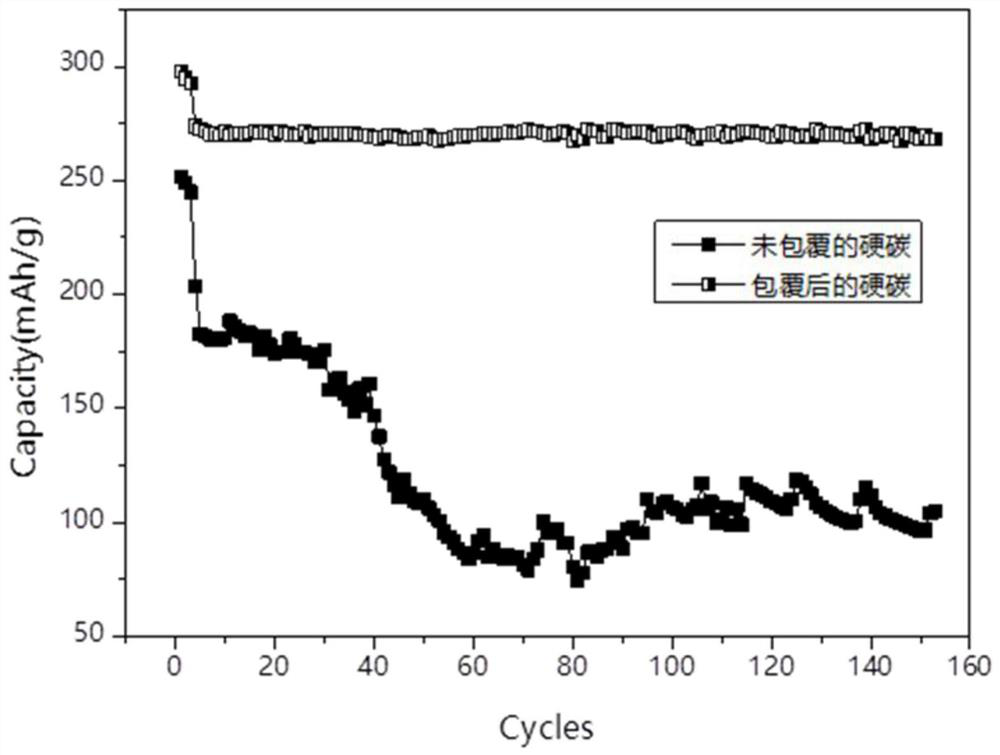

Modified preparation method of hard carbon negative electrode material with high initial efficiency and long cycle life

A technology of cycle life and negative electrode materials, applied in the field of modification and preparation of hard carbon negative electrode materials, can solve the problems of limiting large-rate charge and discharge, low electronic conductivity, low ion conductivity, etc., to improve cycle stability and increase g Capacity, the effect of improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 (comparative example)

[0037] A modification preparation method of a hard carbon carbon negative electrode material for a sodium ion battery, specifically comprising the following steps:

[0038] A: Weigh 10kg of NMP (1-methyl-2-pyrrolidone), 10kg of medium-temperature coal tar pitch and add it to a double planetary mixer, revolution 40r / min, rotation 2500r / min, and stir for 5h;

[0039] B: Weigh 60kg of absolute ethanol and add it to a conical heating mixer with a rotating speed of 160r / min, and simultaneously add 40kg of biomass hard carbon roasted at 1000°C, and stir for 2h;

[0040] C: Weighing 2.4kg of carbon tube slurry with a solid content of 5% will be added to the conical heating mixer of step B in the future, with a rotating speed of 160r / min and stirring for 1.5h;

[0041] D: Add 8 kg of asphalt solution of step A to the mixture of step C, rotate at 160 r / min, stir for 3 h;

[0042] E: Heat and evaporate the mixture in step D to dryness, the h...

Embodiment 2

[0049] A modification preparation method of a hard carbon carbon negative electrode material for a sodium ion battery, specifically comprising the following steps:

[0050] A: Weigh 10kg of NMP (1-methyl-2-pyrrolidone), 10kg of medium-temperature coal tar pitch and add it to a double planetary mixer, revolution 40r / min, rotation 2500r / min, and stir for 5h;

[0051] B: Weigh 30kg of absolute ethanol and add it to a conical heating mixer at a speed of 160r / min, and simultaneously add 40kg of biomass hard carbon roasted at 1000°C, and stir for 2h;

[0052] C: Take 2.4kg of carbon tubes with a solid content of 5% and add them to the conical heating mixer of step B in the future, with a rotating speed of 160r / min and stirring for 1.5h;

[0053] D: Add 8 kg of asphalt solution of step A to the mixture of step C, rotate at 160 r / min, stir for 3 h;

[0054] E: Heat and evaporate the mixture in step D to dryness, the heating temperature is 90°C, the rotation speed is 160r / min, and the...

Embodiment 3

[0058] Embodiment 3 (rotating speed is adjusted to 200r / min by 160r / min in the step B)

[0059] A modification preparation method of a hard carbon carbon negative electrode material for a sodium ion battery, specifically comprising the following steps:

[0060] A: Weigh 10kg of NMP (1-methyl-2-pyrrolidone), 10kg of medium-temperature coal tar pitch and add it to a double planetary mixer, revolution 40r / min, rotation 2500r / min, and stir for 5h;

[0061] B: Weigh 60kg of dehydrated ethanol and join in the conical heating mixer with a rotating speed of 200r / min, and simultaneously add 40kg of biomass hard carbon roasted at 1000°C, and stir for 2h;

[0062] C: Take 2.4kg of carbon tubes with a solid content of 5% and add them to the conical heating mixer of step B in the future, at a speed of 200r / min, and stir for 1.5h;

[0063] D: Add 8 kg of asphalt solution of step A to the mixture of step C, stir at 200 r / min for 3 h at a rotating speed;

[0064] E: Heat and evaporate the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com