Copper foil as well as preparation method and application thereof

A technology of copper foil and rough surface, applied in the field of electronic materials, can solve problems such as difficult to meet peel strength and signal loss at the same time, achieve the effect of improving peel strength, avoiding short circuit phenomenon, and reducing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

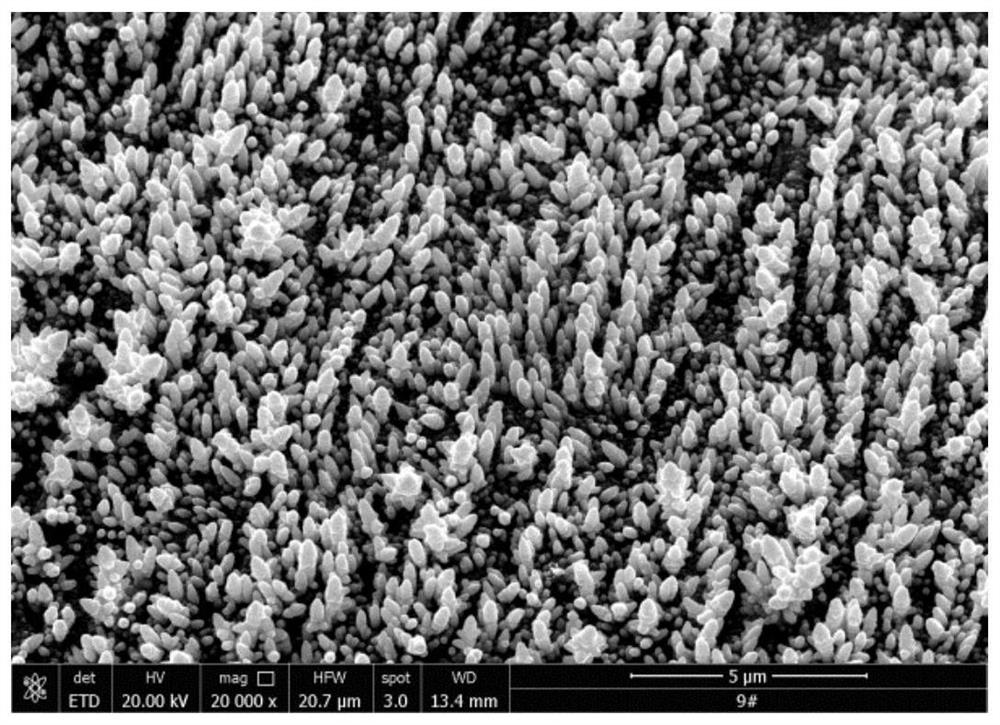

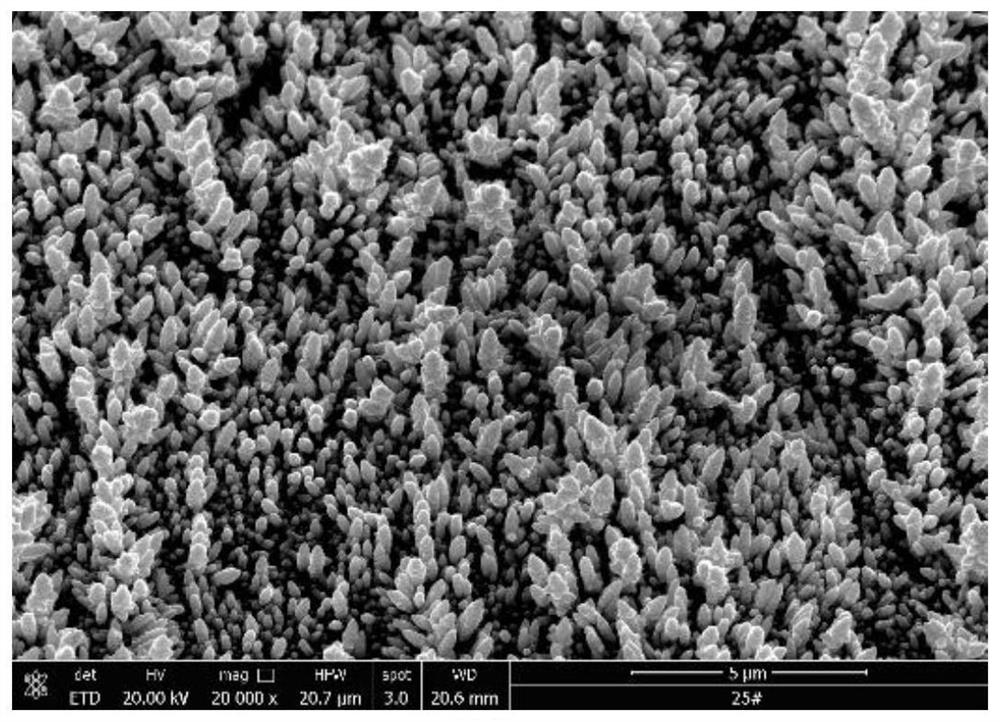

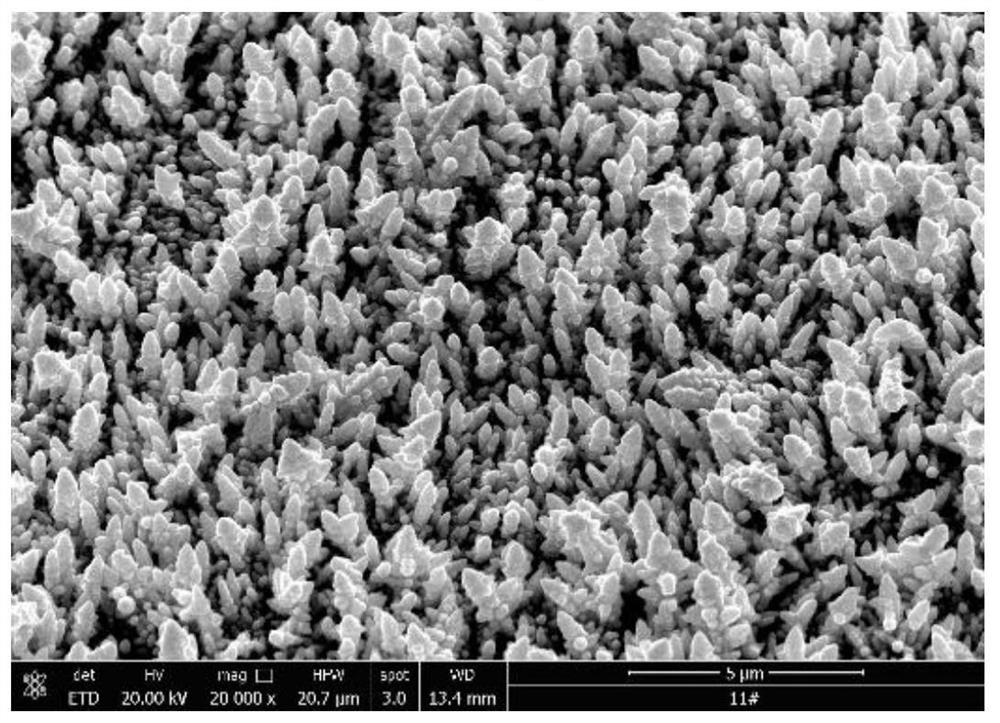

Image

Examples

preparation example Construction

[0030] The second aspect of the present invention provides a method for preparing a copper foil product, wherein the method includes the following steps:

[0031] (1) The raw copper foil is subjected to the first surface treatment in the primary treatment solution to obtain the primary treatment copper foil; wherein, based on the total amount of the primary treatment solution, the primary treatment solution includes copper ions 2- 40g / L, sulfuric acid 50-300g / L, bismuth sulfate 30-400ppm, sodium tungstate 5-250ppm, rare earth salt 20-400ppm;

[0032] (2) Perform a second surface treatment on the primary treated copper foil in the secondary treatment and dosing to obtain a copper foil product; wherein, based on the total amount of the second treatment and dosing, the second treatment and dosing Including copper ion 20-80g / L, sulfuric acid 50-200g / L, chloride ion 50-400ppm.

[0033] In step (1),

[0034] In a preferred embodiment, the raw copper foil has a thickness of 12-70 μ...

Embodiment 1

[0057] (1) Put the raw copper foil with a thickness of 18 μm in the primary treatment solution for the first surface treatment to obtain the primary treatment copper foil; wherein, the copper ions in the primary treatment solution are provided by copper sulfate pentahydrate, and the amount of copper ions Concentration is 10g / L, and the concentration of sulfuric acid is 100g / L, and the concentration of bismuth sulfate is 100ppm, and the concentration of sodium tungstate is 50ppm, and the concentration of terbium sulfate is 100ppm; The condition of described surface treatment for the first time comprises: The limiting current density of surface treatment is 25A / dm 2 , the treatment temperature for the first surface treatment is 20°C, and the treatment time for the first surface treatment is 3s;

[0058] (2) The above-mentioned primary treatment copper foil is subjected to a second surface treatment in the secondary treatment dosing solution to obtain a copper foil product with r...

Embodiment 2

[0060] (1) Put the raw copper foil with a thickness of 18 μm in the primary treatment solution for the first surface treatment to obtain the primary treatment copper foil; wherein, the copper ions in the primary treatment solution are provided by copper sulfate pentahydrate, and the amount of copper ions Concentration is 15g / L, and the concentration of sulfuric acid is 120g / L, and the concentration of bismuth sulfate is 150ppm, and the concentration of sodium tungstate is 20ppm, and the concentration of lanthanum sulfate is 150ppm; The condition of described surface treatment for the first time comprises: The limiting current density of surface treatment is 20A / dm 2 , the treatment temperature for the first surface treatment is 15°C, and the treatment time for the first surface treatment is 2s;

[0061] (2) The above-mentioned primary treatment copper foil is subjected to a second surface treatment in the secondary treatment dosing solution to obtain a copper foil product with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com