A laser additive repair method for 300m steel aircraft landing gear

A technology of aircraft landing gear and laser additive material, which is applied in the direction of additive processing, furnace, heat treatment equipment, etc., can solve the problems of difficult to achieve repair effect, complex structure of landing gear, high repair accuracy requirements, etc., to reduce residual stress and prevent cracking , Improve the effect of surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

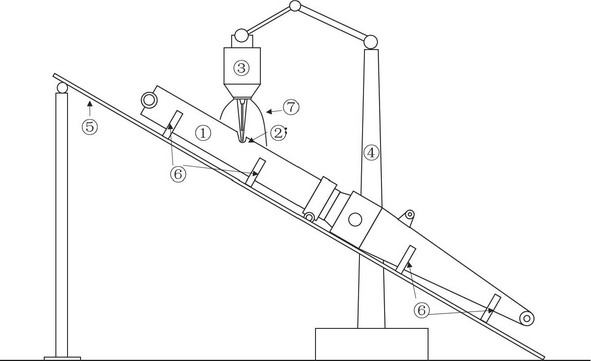

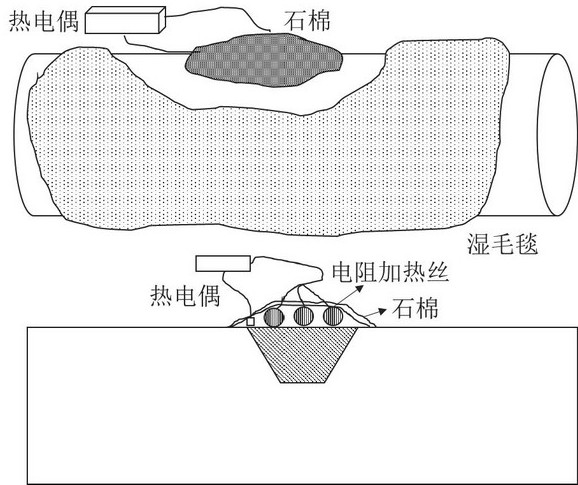

[0028] The technical solutions in the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

[0029] In this embodiment, the substrate to be repaired is a 300m steel landing gear, and the specific laser additive repair process is specifically included as follows:

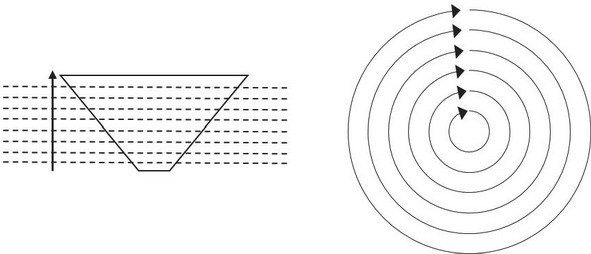

[0030] Slope processing

[0031] There is a need to process the groove in the damage area before the laser add material repair. In the existing repair process, the general grooves are processed in which the heart axis is perpendicular to the landing gear structure (that is, the central axis of the groove is coincident with the normal surface of the landing gear). However, in the case of the actual injury, the cracked expansion direction is not necessarily perpendicular to the surface of the landing gear. At this time, if it still uses the traditional vertical slope processing, it will lead to excessive groove area, and the repair area has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com