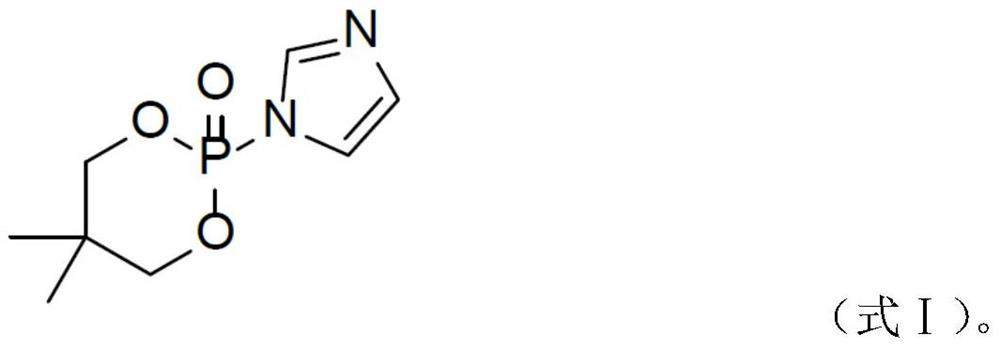

A kind of phosphorus nitrogen flame retardant and its preparation method and application

A technology of flame retardant and phosphorus nitrogen, which is applied in the field of flame retardants, can solve the problems of poor hand feeling and resistance to washing, and achieve the effects of small loss of strength, easy operation, environmental protection and pollution-free application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

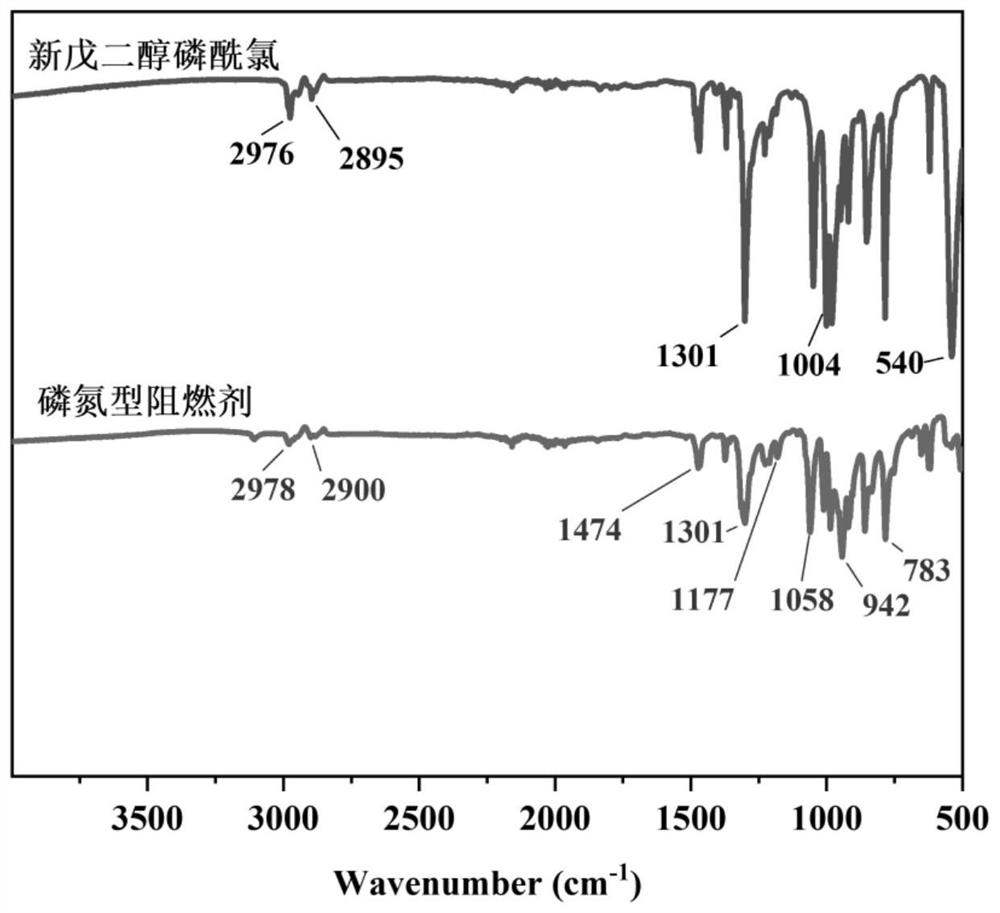

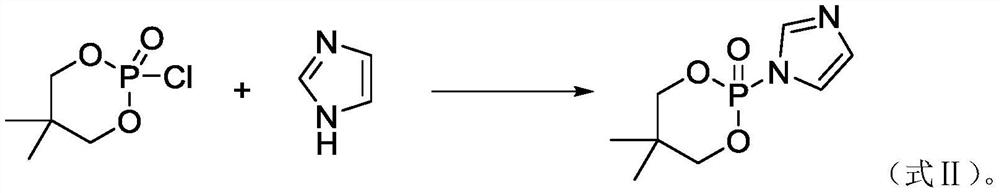

[0035] 1. Synthetic intermediate neopentyl glycol phosphorus oxychloride

[0036] In a three-necked flask equipped with a spherical condenser, a thermometer and a magnetic stirring device, first add 0.1 mol of neopentyl glycol, then add 50 mL of dichloromethane as a solvent, and stir to completely dissolve the neopentyl glycol in the solvent, keeping the temperature at 3 °C , and then dropwise added 0.11mol phosphorus oxychloride, after the dropwise addition, the temperature was raised to 55 ° C, and the reaction was continued for 5 h until no hydrogen chloride was released; after the reaction was completed, it was cooled to room temperature, and the solvent and unreacted trichloride were removed by distillation under reduced pressure. Phosphorus oxide, washed three times with n-hexane, and dried in vacuum, which is the intermediate neopentyl glycol phosphorus oxychloride.

[0037] 2. Preparation of phosphorus nitrogen flame retardant

[0038] Under the protection of nitrogen...

Embodiment 2

[0047] 1. Synthetic intermediate neopentyl glycol phosphorus oxychloride

[0048] In a three-necked flask equipped with a spherical condenser, a thermometer and a magnetic stirring device, first add 0.2 mol of neopentyl glycol, then add 100 mL of dichloromethane as a solvent, stir to make the neopentyl glycol completely dissolve in the solvent, and keep the temperature at 3 °C , and then dropwise added 0.22mol phosphorus oxychloride, after the dropwise addition, the temperature was raised to 55 ° C, and the reaction was continued for 5 h until no hydrogen chloride was released; after the reaction was completed, it was cooled to room temperature, and the solvent and unreacted trichloride were removed by distillation under reduced pressure. Phosphorus oxide, washed three times with n-hexane, and dried in vacuum, which is the intermediate neopentyl glycol phosphorus oxychloride.

[0049] 2. Preparation of phosphorus nitrogen flame retardant

[0050] Under the protection of nitro...

Embodiment 3

[0058] 1. Synthetic intermediate neopentyl glycol phosphorus oxychloride

[0059] In a three-necked flask equipped with a spherical condenser, a thermometer and a magnetic stirring device, first add 0.3 mol of neopentyl glycol, then add 150 mL of dichloromethane as a solvent, stir to make the neopentyl glycol completely dissolve in the solvent, and keep the temperature at 3 °C , and then dropwise added 0.33mol phosphorus oxychloride, after the dropwise addition, the temperature was raised to 55 ° C, and the reaction was continued for 5 h until no hydrogen chloride was released; after the reaction was completed, it was cooled to room temperature, and the solvent and unreacted trichloride were removed by distillation under reduced pressure. Phosphorus oxide, washed three times with n-hexane, and dried in vacuum, which is the intermediate neopentyl glycol phosphorus oxychloride.

[0060] 2. Preparation of phosphorus nitrogen flame retardant

[0061] Under the protection of nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com