Preparation method of cannabis sativa leaf extract water-soluble micro-capsule

A technology of extracts and cannabis leaves, which is applied in the field of preparation, can solve the problems of poor solubility and stability of cannabidiol, and achieve the effects of improving bioavailability and effect, good dispersion, and improving solubility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

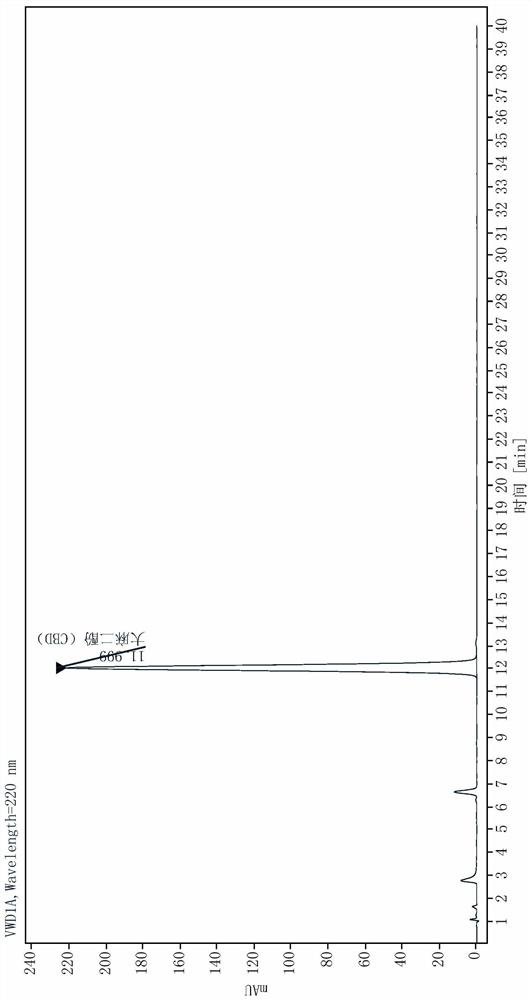

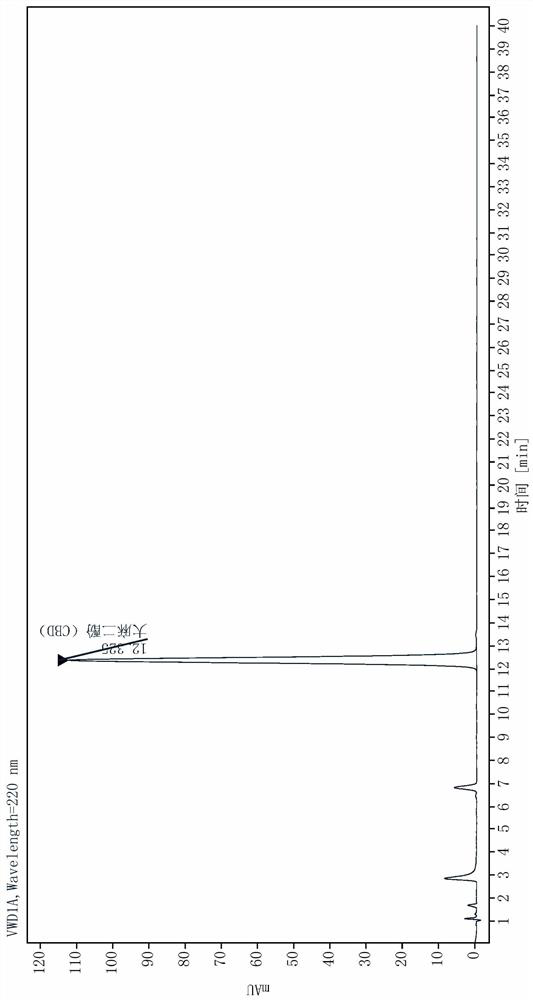

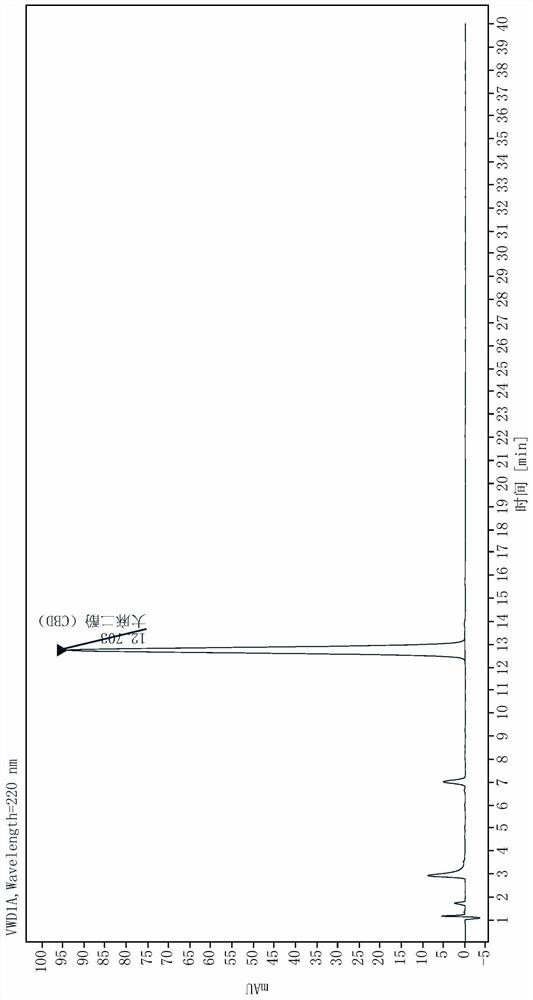

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: This embodiment is a method for preparing water-soluble microcapsules of cannabis leaf extract, which is specifically completed according to the following steps:

[0021] 1. Wall material preparation: ①, emulsifier preparation; disperse glyceryl monostearate in hot distilled water to obtain emulsifier; Essence and gum arabic are added to the emulsifier, and mixed to obtain the wall material mixture;

[0022] 2. Core material preparation: dissolve the cannabis leaf extract in caprylic capric acid glyceride, and mix to obtain the core material mixture;

[0023] 3. Forming: Add distilled water to the core material mixture, then add the wall material mixture, first use a high-speed shearing machine for rough shearing, then high-pressure homogenize for 1 to 3 times, and finally spray dry to obtain a water-soluble cannabis leaf extract Microcapsules.

[0024] β-cyclodextrin has a hole in the center of the ring structure, and there is an oxygen atom in which -C...

specific Embodiment approach 2

[0027] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the mass ratio of glyceryl monostearate described in step 1. to hot distilled water is (2~5)g:(25~30) mL. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass ratio of β-cyclodextrin and gum arabic described in step 1② is (10~20):1; the arabic The mass ratio of glyceryl monostearate in the gum to the emulsifier is (1-2):1. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com