Color-controllable zeolite modification method

A zeolite and color technology, applied in the field of color-controllable zeolite modification, can solve problems such as affecting the performance of zeolite adsorptive supported photocatalysts, and achieve the effects of good adsorption and photocatalytic performance, convenient operation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

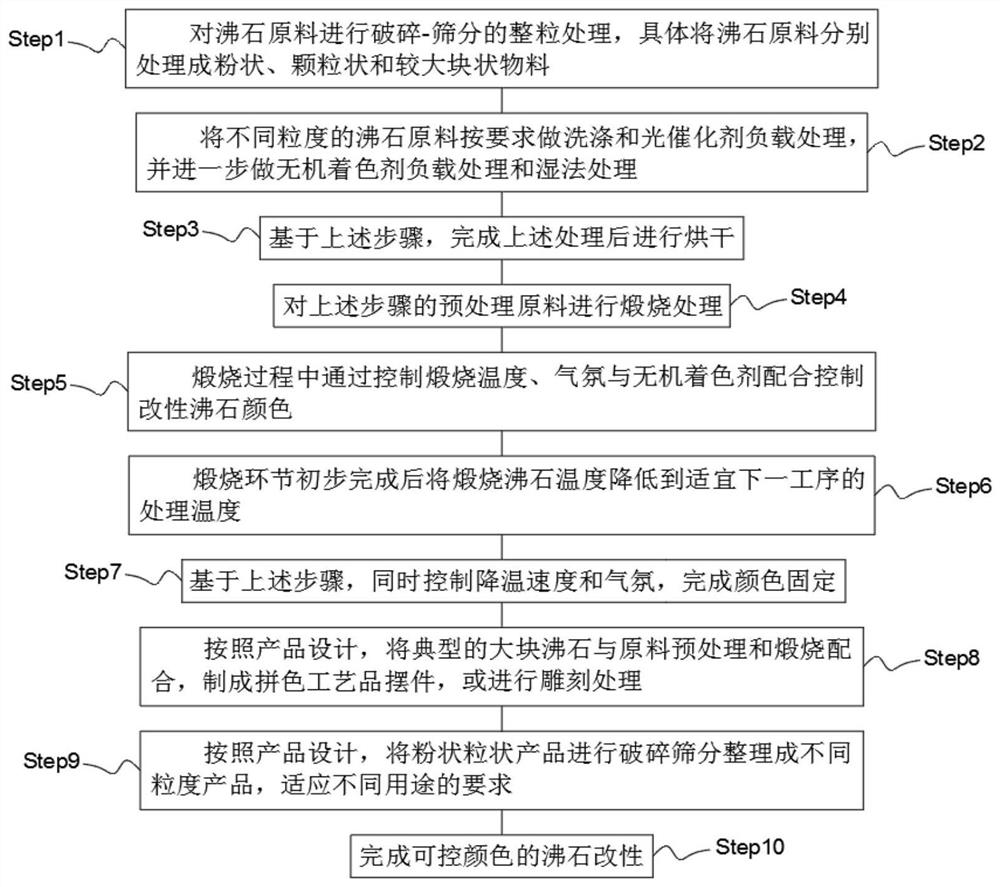

Method used

Image

Examples

Embodiment 1

[0050] Using Liaoning Beipiao turquoise zeolite as raw material, crush and select large zeolite with an average particle size of 300mm, wash with deionized water, impregnate and coat Ti-based photocatalyst with a loading capacity of 5%-25% TiO 2 ;After drying, put it into the furnace for calcination, the heating rate is 10°C / min, the holding temperature is 450°C, the holding time is 3h, calcining in a weak oxidizing atmosphere; the cooling rate is 50°C / min, cooling in a weak oxidizing atmosphere. After calcination, the modified zeolite has the same particle size and orange-red color, and the adsorption capacity increases by about 25%. The 40L photocatalytic decomposition of formaldehyde test shows that the decomposition rate of formaldehyde is 34% after 20 minutes of light.

Embodiment 2

[0052] Using Liaoning Beipiao green zeolite as raw material, 2mm-5mm granular zeolite particles are obtained by crushing, screening and granulation. After cleaning with deionized water, dipping and coating Ti-based photocatalyst with a loading capacity of 5%-45%TiO 2 ; After drying, put it into the furnace for calcination, the heating rate is 5°C / min, the holding temperature is 450°C, the holding time is 2h, calcining in a weak reducing atmosphere; the cooling rate is 50°C / min, nitrogen protection. After calcination, the modified zeolite has the same particle size, turquoise color, and the adsorption capacity increases by about 35%. The 40L photocatalytic decomposition of formaldehyde test shows that the decomposition rate of formaldehyde is 42% after 20 minutes of light.

Embodiment 3

[0054] Using Liaoning Beipiao green zeolite as raw material, 0.5mm-0.35mm granular zeolite particles are obtained by crushing, screening and granulation. After cleaning with deionized water, impregnated and coated with Ti-based photocatalyst, the loading capacity is 5%-45%TiO 2 ;After drying, put it into the furnace for calcination, the heating rate is 5°C / min, the holding temperature is 450°C, the holding time is 2h, calcining in a weak reducing atmosphere; the cooling rate is 50°C / min, natural wind. After calcining, the modified zeolite has the same particle size, off-white color, and the adsorption capacity increases by about 35%. The 40L photocatalytic decomposition of formaldehyde test shows that the decomposition rate of formaldehyde is 39% after 20 minutes of light.

[0055] In this scheme, the raw material pretreatment process includes: granulation, photocatalyst loading, washing, and drying steps to provide raw materials for calcining, modifying and color fixing; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com