Environment-friendly and energy-saving lime sintering process

A technology of lime sintering, environmental protection and energy saving, applied in the field of lime production technology, can solve the problems of large flue gas pollution, high energy consumption, unfavorable ecological environment protection, etc., and achieve good environmental protection and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

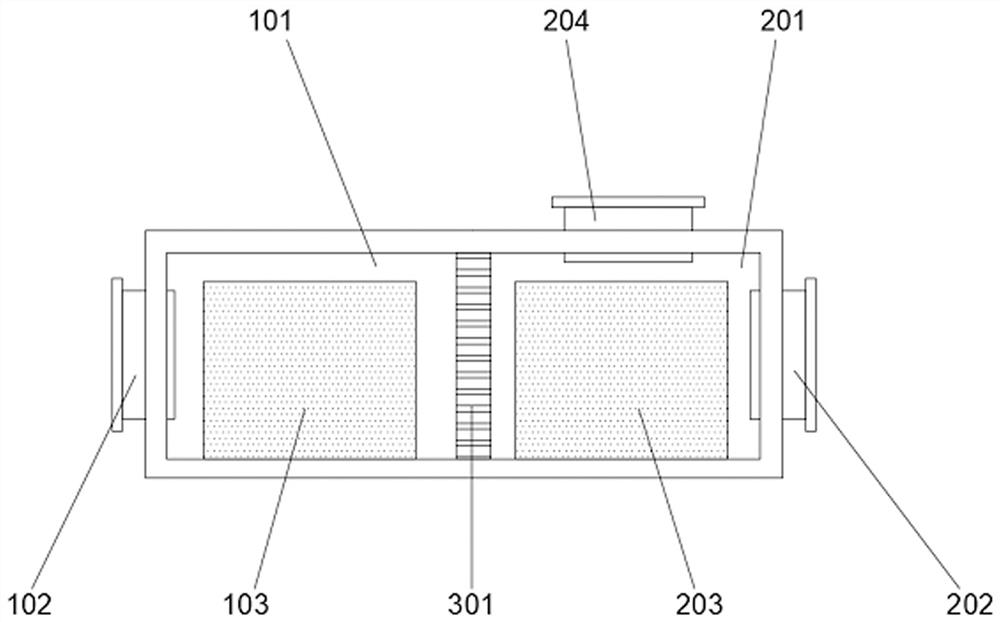

Image

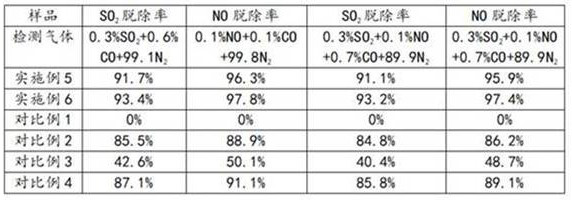

Examples

Embodiment 1

[0037] This embodiment is an adsorption filter element, and the preparation method of the adsorption filter element comprises the following steps:

[0038] A1: Wash the phenolic fiber twice with distilled water and absolute ethanol, then air-dry it, then dissolve zinc chloride in deionized water, then add the washed phenolic fiber, soak it for 1 hour, and place it in a vacuum drying oven. Dry at 65°C to constant weight to obtain pretreated fibers; control the dosage ratio of phenolic fiber, zinc chloride, and deionized water to 1g: 20mL: 8g;

[0039]A2: Put the pretreated fiber into the tube furnace, feed nitrogen and control the flow rate to 50mL / min, raise the temperature to 900°C under the condition of feeding nitrogen protection, control the heating rate to 2°C / min, then keep the temperature for 2h, and cool Take out after reaching room temperature, obtain active carbon fiber;

[0040] A3: Wash the activated carbon fiber with hydrochloric acid solution, and then wash it w...

Embodiment 2

[0043] This embodiment is an adsorption filter element, and the preparation method of the adsorption filter element comprises the following steps:

[0044] A1: Wash the phenolic fiber with distilled water and absolute ethanol three times respectively, then air-dry it, then dissolve zinc chloride in deionized water, then add the washed phenolic fiber, soak it for 2 hours, and place it in a vacuum drying oven. Dry at 75°C to constant weight to obtain pretreated fibers; control the dosage ratio of phenolic fiber, zinc chloride, and deionized water to 1g: 50mL: 8g;

[0045] A2: Put the pretreated fiber into the tube furnace, feed nitrogen and control the flow rate to 50mL / min, raise the temperature to 900°C under the condition of feeding nitrogen protection, control the heating rate to 5°C / min, then keep the temperature for 3h, and cool Take out after reaching room temperature, obtain active carbon fiber;

[0046] A3: Wash the activated carbon fiber with hydrochloric acid solutio...

Embodiment 3

[0049] Present embodiment is a kind of reaction catalyst, and the preparation method of reaction catalyst comprises the following steps:

[0050] B1: Add cerium nitrate and titanium sulfate to deionized water respectively to prepare cerium nitrate solution and titanium sulfate solution, and then mix the cerium nitrate solution and titanium sulfate solution evenly to obtain mixed solution A; control the cerium nitrate solution and titanium sulfate solution The concentration of the substance is 0.2mol / L, the volume ratio of cerium nitrate solution and titanium sulfate solution is 1:3;

[0051] B2: Add ammonia water dropwise to the ammonium chloride solution until the pH value of the solution is 10 to obtain a mixed solution B; control the concentration of the ammonia water to 6 mol / L, and the ammonium chloride solution to a concentration of 1 mol / L ;

[0052] B3: Dissolve polyethylene glycol 600 in deionized water and add it to mixed solution B, mix well to obtain mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com