PEG styptic powder

A hemostatic powder, PEG-1 technology, applied in medical science, drug delivery, bandages, etc., can solve the problems of no interaction between tissues, easy to break, and low strength of colloids, and achieve good biocompatibility and increased strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The synthesis of four-arm polyethylene glycol aldehyde group is as follows [1] : P-aldehyde benzoic acid (150mg, 10eq.), 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (191.7mg, 10eq.) and 4-dimethylamino Pyridine (61.08mg, 5eq.) was dissolved in 50ml of anhydrous dichloromethane, four-armed polyethylene glycol (1g, 1eq.) was added and reacted at room temperature for 24 hours. Then the solution after the reaction was extracted and washed with 1M hydrochloric acid (3×40mL), saturated sodium bicarbonate (3×40mL), and saturated brine (3×40mL) respectively, and the organic layer was collected after washing, and then anhydrous MaSO 4 Drying, filtering, and rotary evaporation to remove the solvent, the final product was dried in a vacuum oven with a yield of 90%. 1 H NMR (300MHz, CDCl 3 ): δ3.25(t, 8H; CH 2 ), 3.64 (bs, ~1000H; OCH 2 CH 2 O), 3.85(s, 8H; CH 2 CH 2 OCO), 4.61(s, 8H; CH 2 OCO), 7.95 (m, 8H; Ar-H), 8.24 (m, 8H; Ar-H), 10.03 (m, 4H; CHO); 13...

Embodiment 2

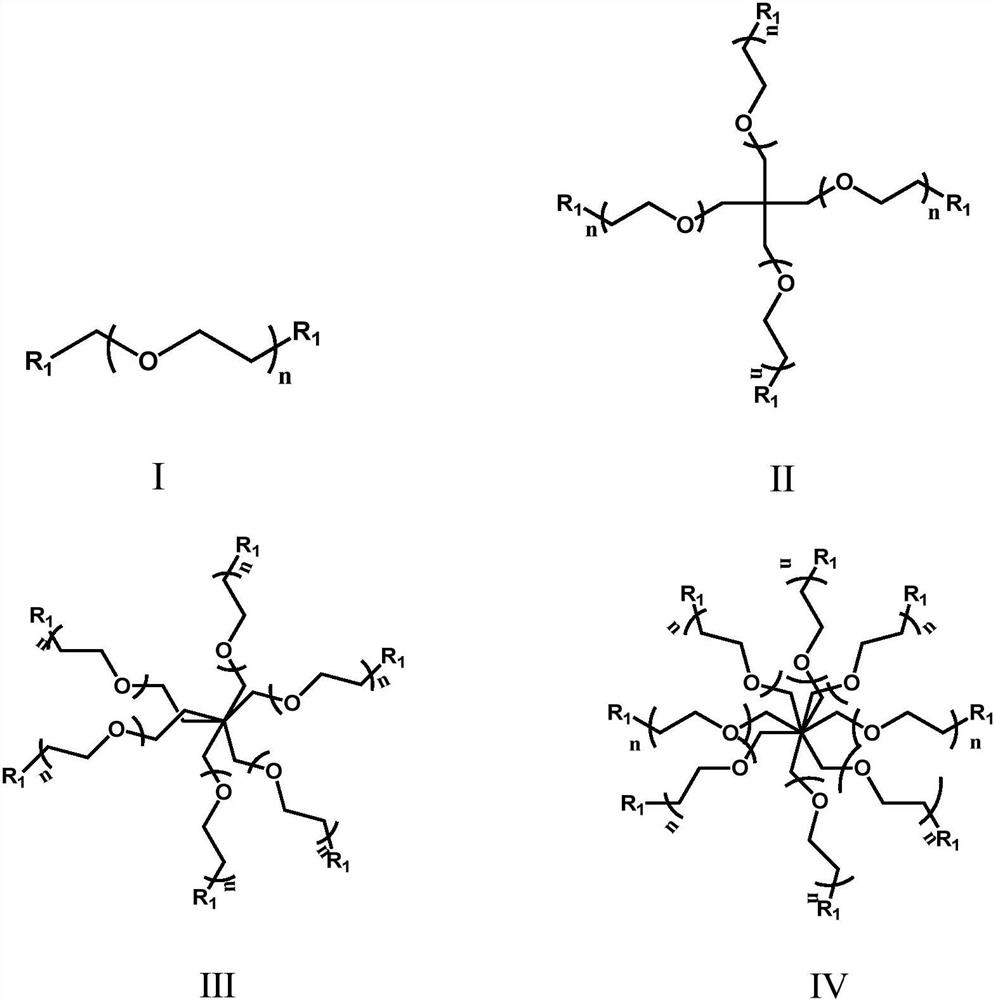

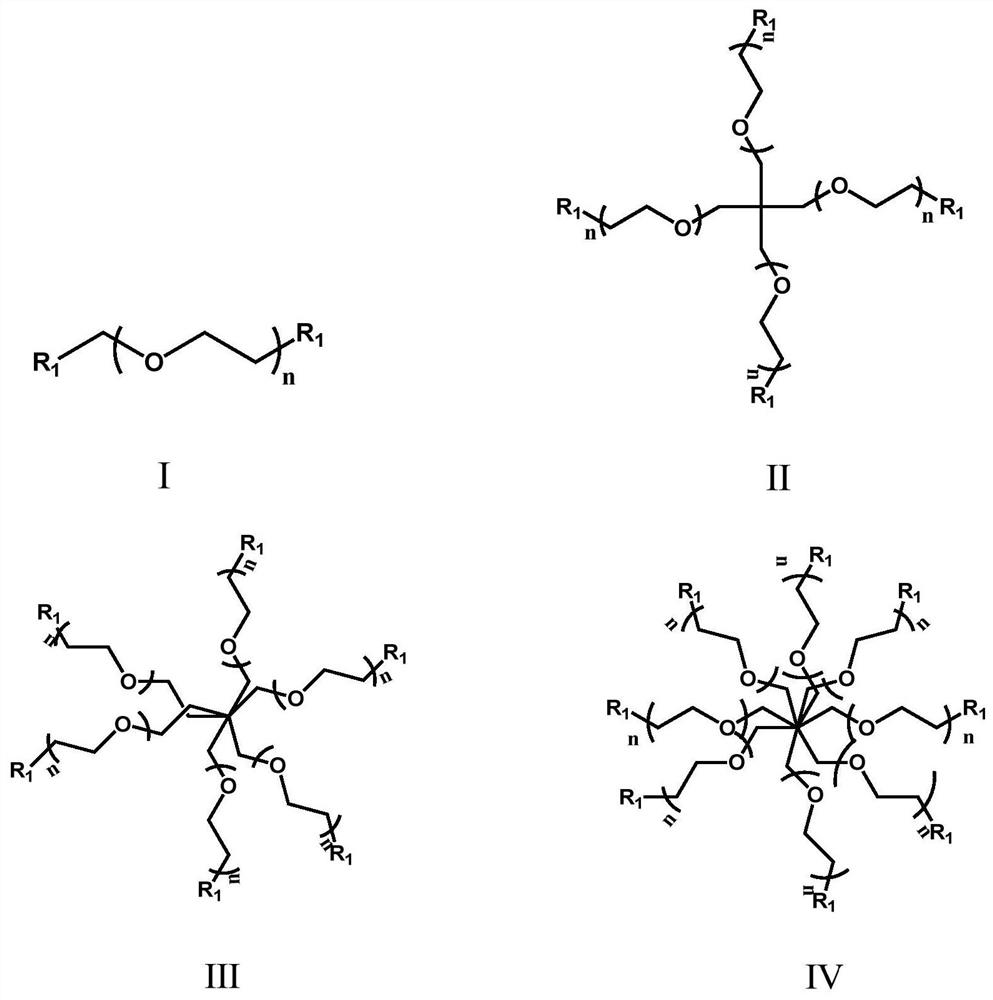

[0046] Take by weighing 200mg four-arm polyethylene glycol amino (as shown in formula II, wherein, n is 112, R 1 is amino), weigh 200mg eight-arm polyethylene glycol succinimide succinimide ester group (as shown in formula IV, wherein, n is 112, R 1 It is succinimide ester group of succinate), and after mixing evenly with a vibrator, the water absorption rate of the system is 45 times.

[0047] According to the method in Example 1, the adhesion strength measured by a universal tensile machine was 46Kpa.

[0048] The degradation performance of the hydrogel prepared in this example was tested according to the method in Example 1, and the degradation time was measured to be 3 days.

Embodiment 3

[0050] Take by weighing 100mg eight-arm polyethylene glycol glutaric acid succinimide ester (as shown in formula IV, wherein, n is 56, R 1 is glutaric acid succinimide ester group), weighed 200mg four-arm polyethylene glycol mercapto (as shown in formula II, wherein, n is 48, R 1 for mercapto), using a shaker to mix evenly, and the water absorption rate is 54 times.

[0051] According to the method in Example 1, the adhesion strength of the system was measured by a universal tensile machine to be 39kPa, which indicated that the gel could be well attached to the surface of pigskin.

[0052] The degradation performance of the hydrogel prepared in this example was tested according to the method in Example 1, and the degradation time was measured to be 10 days.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com