Method for preparing high-purity iron phosphate from iron-containing slag

A technology of high-purity phosphoric acid and iron phosphate, applied in chemical instruments and methods, crystal growth, recycling by waste collectors, etc., can solve problems such as environmental pollution and resource waste, and solve serious resource waste and environmental pollution problems and environmental impacts. Small size and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

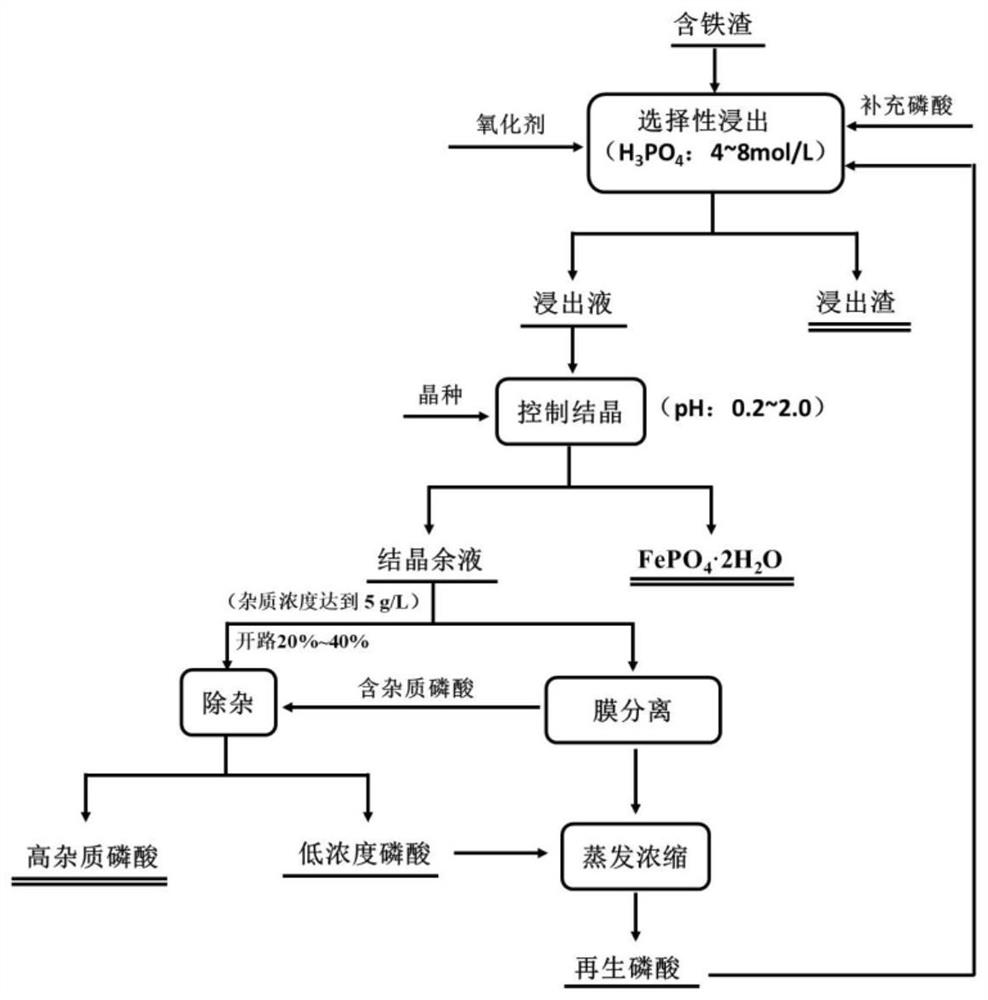

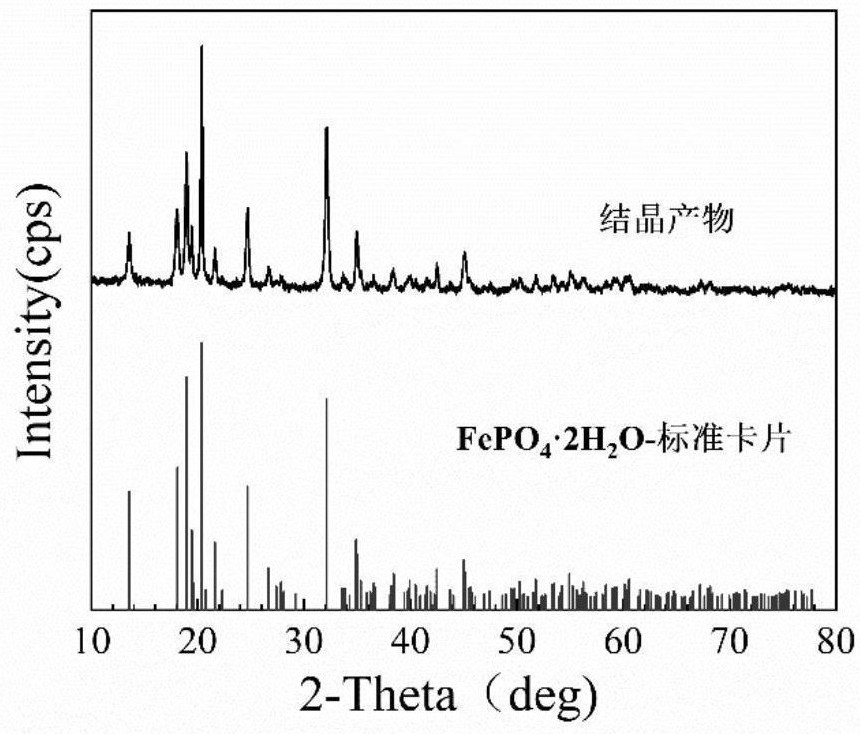

[0053] according to figure 1 In the process flow diagram shown, 7 mol / L phosphoric acid is added to the sulfuric acid pressure leaching residue of laterite nickel ore containing 48.2% iron at a solid-to-liquid ratio of 1:6 g / mL, and the concentration of hydrogen peroxide is 0.1 mol / L. The selective leaching temperature is controlled at 85°C, the leaching time is 3h, and the stirring speed is set at 200rpm; solid-liquid separation, and the leaching slag can be sold as raw materials for preparing cement ceramics. Add 2 times the volume of water to the leaching solution for dilution, maintain the pH of the system at 0.5, and add 80g / L ferric phosphate as a seed crystal and CTAB with an iron content of 0.1% as a surfactant, the crystallization temperature is 80 ° C, and the time is 24h, the stirring speed is 100rpm; after the crystallization, solid-liquid separation, the crystallized product is dried in an oven at 80°C for 12h to obtain ferric phosphate dihydrate, see figure 2 ....

Embodiment 2

[0055] according to figure 1 In the process flow diagram shown, 5 mol / L phosphoric acid is added to red mud containing 25.0% iron at a solid-to-liquid ratio of 1:10 g / mL, the concentration of hydrogen peroxide is 0.5 mol / L, and the selective leaching temperature is controlled as 80°C, the leaching time is 4h, and the stirring speed is set at 500rpm; solid-liquid separation, and the leaching residue can be sold as raw materials for making cement ceramics. Add 5 times the volume of water to the leachate for dilution, maintain the pH of the system at 2.0, and add 50 g / L of ferric phosphate as a seed crystal and SDS with an iron content of 0.2% as a surfactant. The crystallization temperature is 85 ° C, and the time is After 18 hours, the stirring speed was 50 rpm; after the crystallization was completed, the solid and liquid were separated, and the crystallized product was dried in an oven at 80° C. for 12 hours to obtain ferric phosphate dihydrate. The remaining crystallization...

Embodiment 3

[0057] according to figure 1 In the process flow chart shown, 8mol / L phosphoric acid is added to the laterite nickel ore pyro-smelting slag containing 32.0% iron at a solid-to-liquid ratio of 1:8g / mL, and oxygen is passed through the system at a flow rate of 5ml / min, the selective leaching temperature is controlled at 70°C, the leaching time is 0.5h, and the stirring speed is set at 400rpm; solid-liquid separation, leaching slag can be sold as raw materials for making cement ceramics. Add 0.5 times the volume of water to the leachate for dilution, maintain the pH of the system at 0.2, and add 10 g / L of ferric phosphate as a seed crystal and SDBS with an iron content of 0.5% as a surfactant. The crystallization temperature is 90 ° C, and the time is 6h, the stirring speed is 300rpm; after the crystallization is completed, the solid and liquid are separated, and the crystallized product is dried in an oven at 80°C for 12h to obtain ferric phosphate dihydrate. 20% of the remain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com