Preparation method of pore-adjustable porous activated carbon electrode material

An electrode material and activated carbon technology, which is applied in the field of preparation of porous activated carbon electrode materials, can solve the problem that the energy density of supercapacitors cannot reach that of lithium-ion batteries, and achieve the effect of simple operation and high pore controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

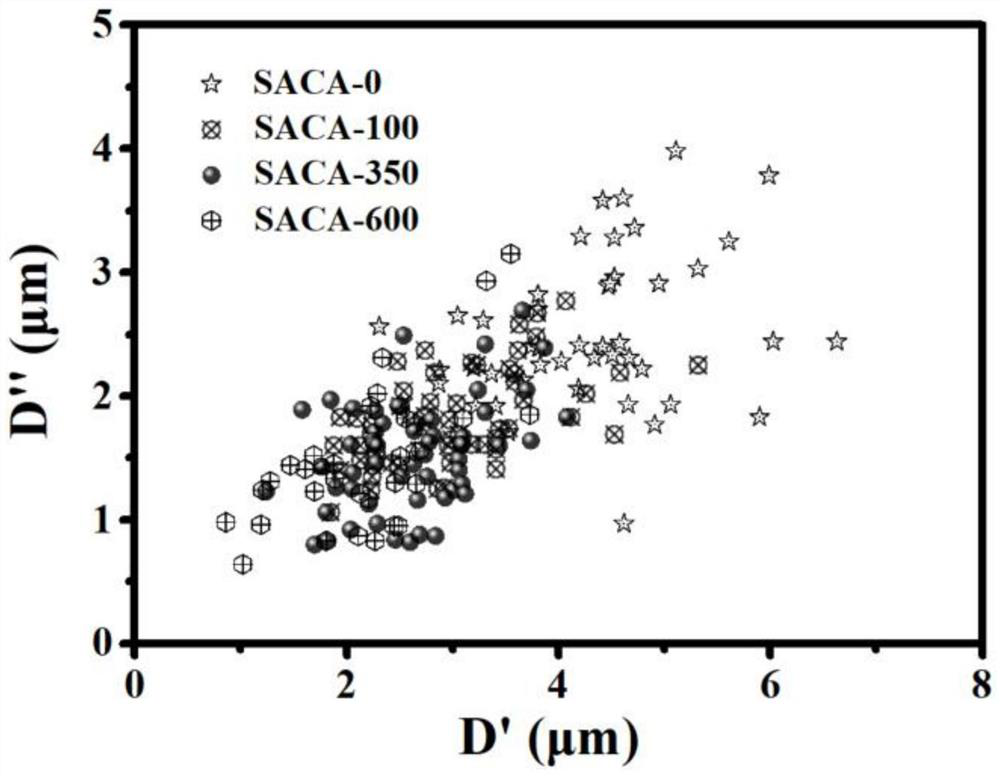

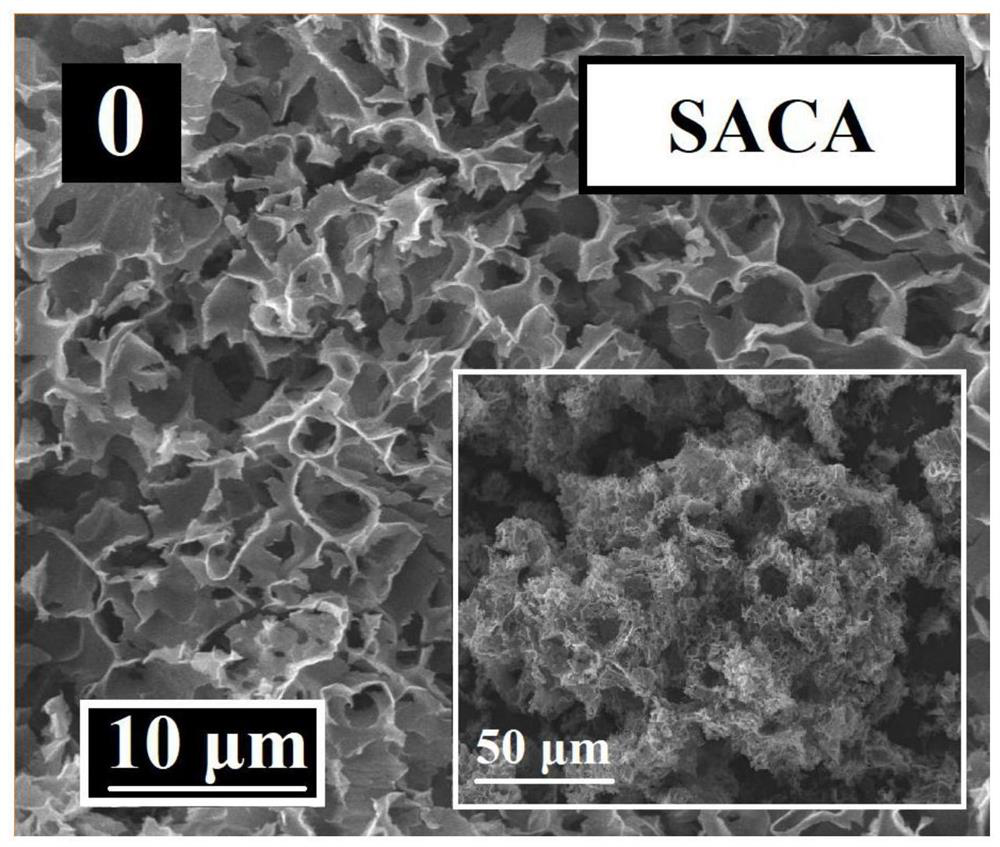

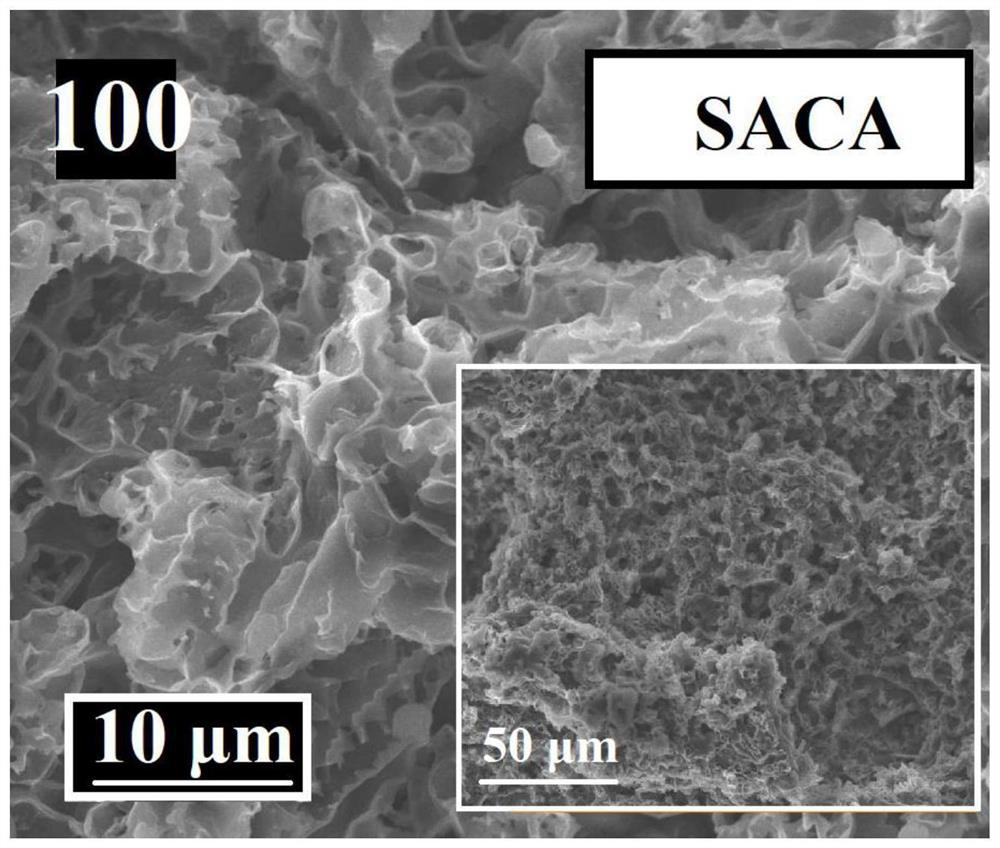

[0049] Dissolve sodium acrylate in water to form a 30% sodium acrylate solution, then add sodium hydroxide to adjust the pH of the solution to neutral, then add starch, polyethylene glycol and K 2 S 2 o 8Carry out graft copolymerization reaction at 25° C. for 6 hours to form starch acrylic acid polymer and dry to obtain starch acrylic acid-based superabsorbent resin. Put the starch acrylic acid-based superabsorbent resin into the cationic dye methylene blue aqueous solution to absorb water and swell. The concentrations of the methylene blue aqueous solution are 0mg / L, 30mg / L, 60mg / L and 100mg / L. The superabsorbent resin is freeze-dried to obtain a superabsorbent resin-based aerogel containing dyes. Mix superabsorbent resin-based airgel and alkali metal compound 1:1 and grind for 10 minutes to obtain a mixture. Put the mixture in a tube furnace to heat up to 800°C at 5°C / min and keep it warm for 60 minutes for carbonization and activation. The obtained product Wash with deio...

Embodiment 2

[0051] Dissolve potassium acrylate in water to form a 40% sodium acrylate solution, then add sodium hydroxide to adjust the pH of the solution to neutral, then add starch, polyethylene glycol and K 2 S 2 o 8 Carry out graft copolymerization reaction at 40° C. for 12 hours to form starch acrylic acid polymer and dry to obtain starch acrylic acid-based superabsorbent resin. Put the starch acrylic acid-based superabsorbent resin into the cationic dye malachite green aqueous solution for water absorption and swelling. The concentration of the malachite green aqueous solution is 0mg / L, 100mg / L, 200mg / L and 300mg / L respectively. The superabsorbent resin after swelling is freeze-dried to obtain a superabsorbent resin-based aerogel containing dye. Mix superabsorbent resin-based airgel with alkali metal compound 1:2 and grind for 10 minutes to obtain a mixture. Put the mixture in a tube furnace to heat up to 1000°C at 8°C / min and keep it warm for 90 minutes for carbonization activati...

Embodiment 3

[0053] Dissolve potassium acrylate in water to form a 50% sodium acrylate solution, then add sodium hydroxide to adjust the pH of the solution to neutral, then add starch, polyethylene glycol and K 2 S 2 o 8 Carry out graft copolymerization reaction at 60° C. for 24 hours to form starch acrylic acid polymer, and dry to obtain starch acrylic acid-based superabsorbent resin. Put the starch acrylic acid-based superabsorbent resin into the cationic dye gentian violet solution for water absorption and swelling. The concentrations of the gentian violet solution are 50mg / L, 100mg / L, 150mg / L and 200mg / L respectively. The superabsorbent resin after swelling is freeze-dried to obtain a superabsorbent resin-based aerogel containing dye. Mix superabsorbent resin-based airgel with alkali metal compound 1:1.5 and grind for 15 minutes to obtain a mixture. Put the mixture in a tube furnace to heat up to 1200°C at 10°C / min and keep it warm for 120 minutes for carbonization and activation. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com